2014 FRC Build Season Blog

Day 45: Autonomous Updates

Over the weekend, the software team was hard at work on 3 ball autonomous routines. Here’s some video.

Also, shooting on the move works quite nicely.

Day 45: Home Stretch

by Dorian Chan and Abhishek Aditham

Programming

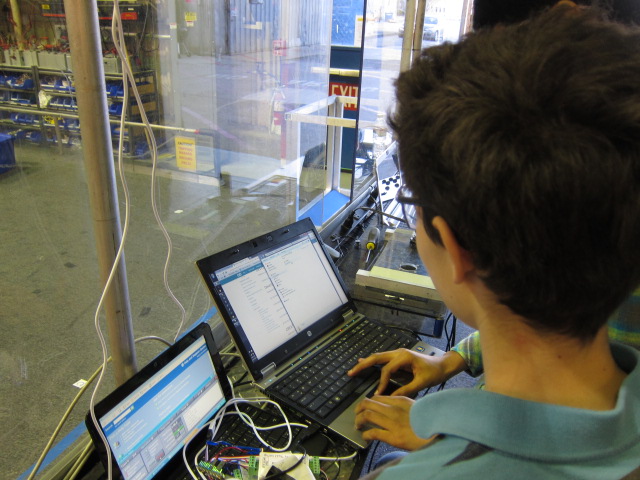

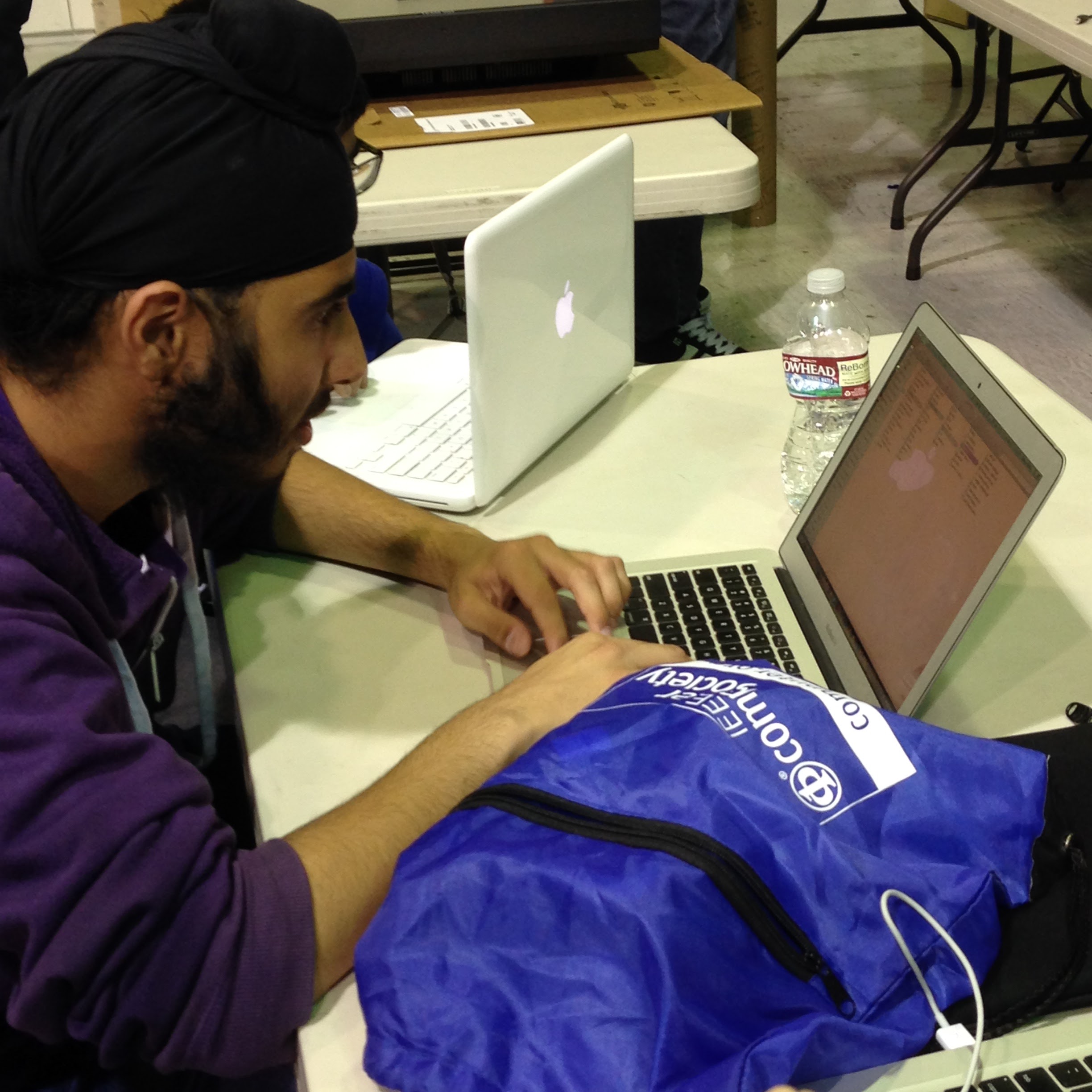

Today the programmers worked on state machines for the shooter on the robot. They have been using state machines for various subsystems on the robot in order to control and interact with them. State machines track what state the robot is in and change the state based on input.

The web guys worked on creating a pit display for competition, where people will be able to view information about the team’s robot.

Parts Organization

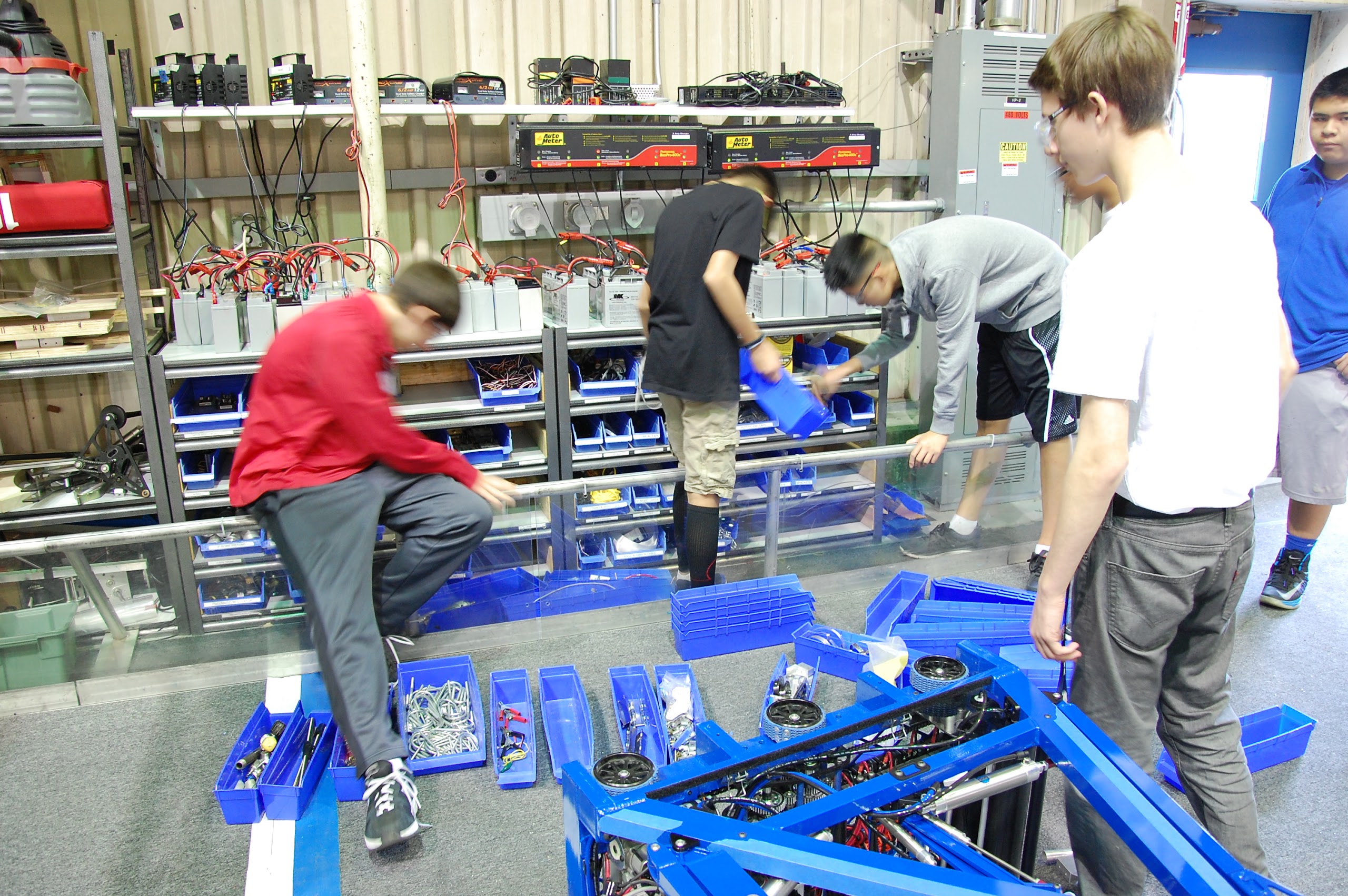

Team members worked on sorting miscellaneous parts into blue bins. By organizing misplaced parts, the team will be more efficient at finding parts it needs.

Machining

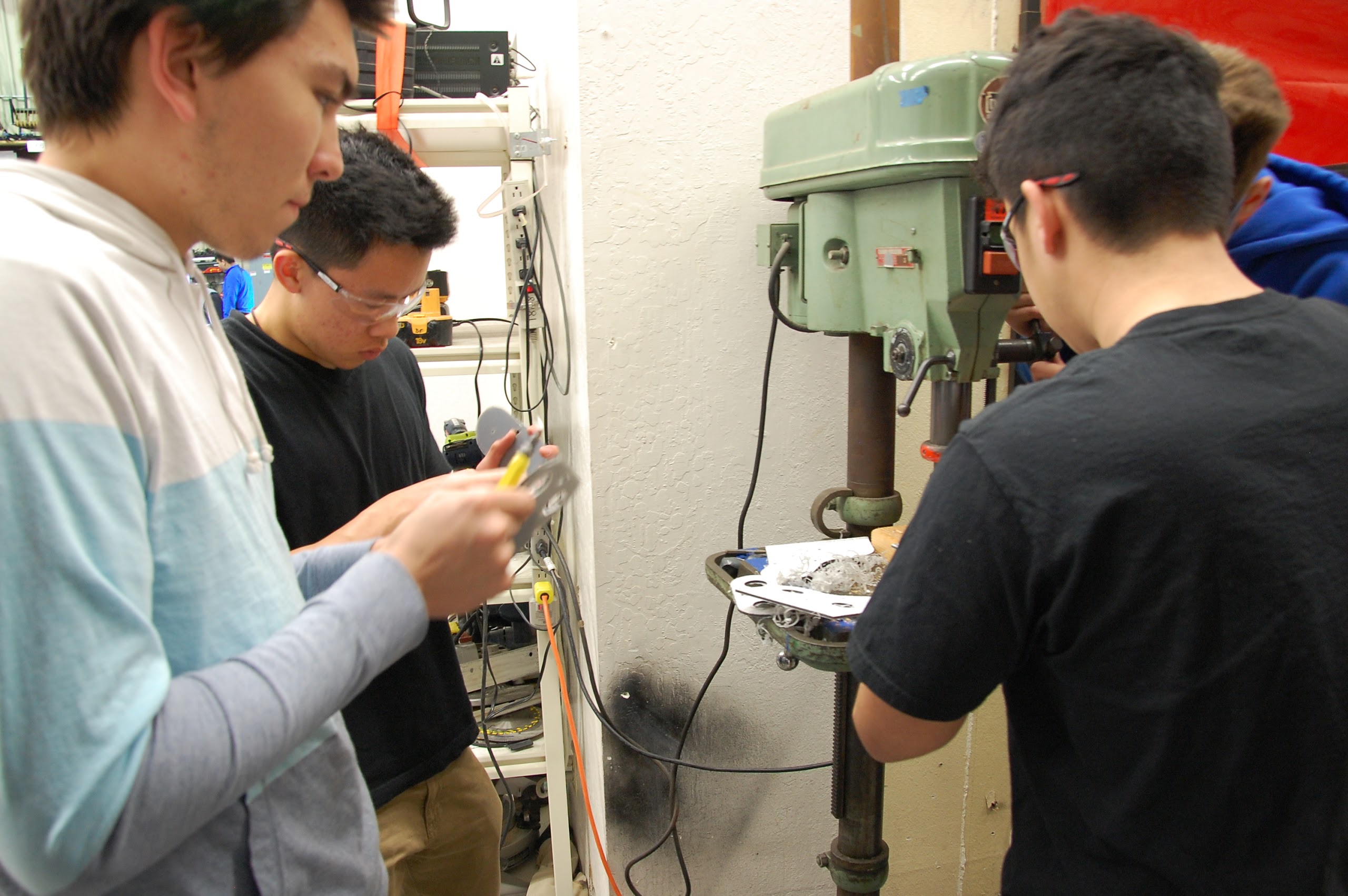

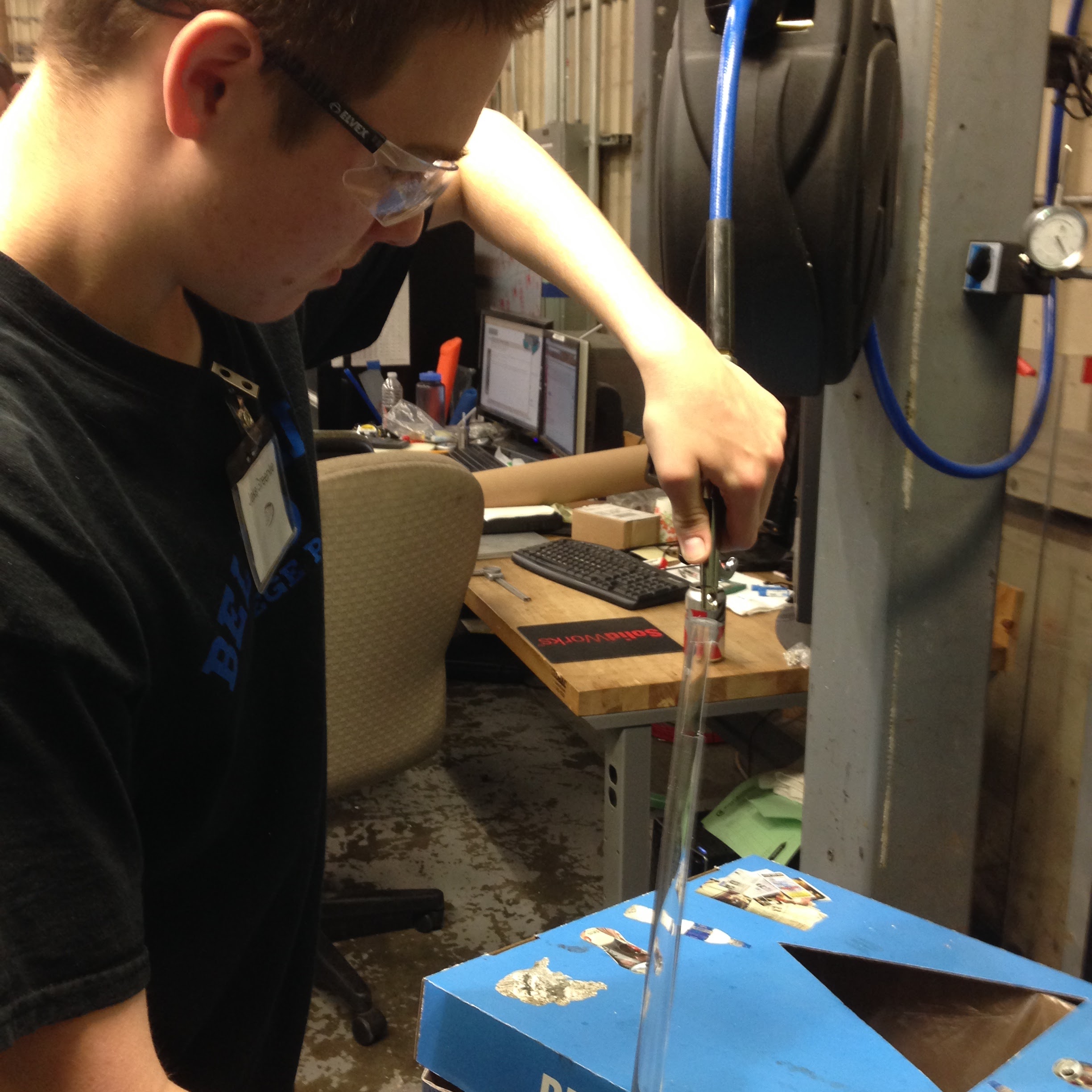

Some students worked on creating mounts made out of polycarb for the robot’s air tanks using the drillpress and the bandsaw. They later put the tanks onto the robot using the mounts and worked on finishing the pneumatic system.

Electronics and Wiring

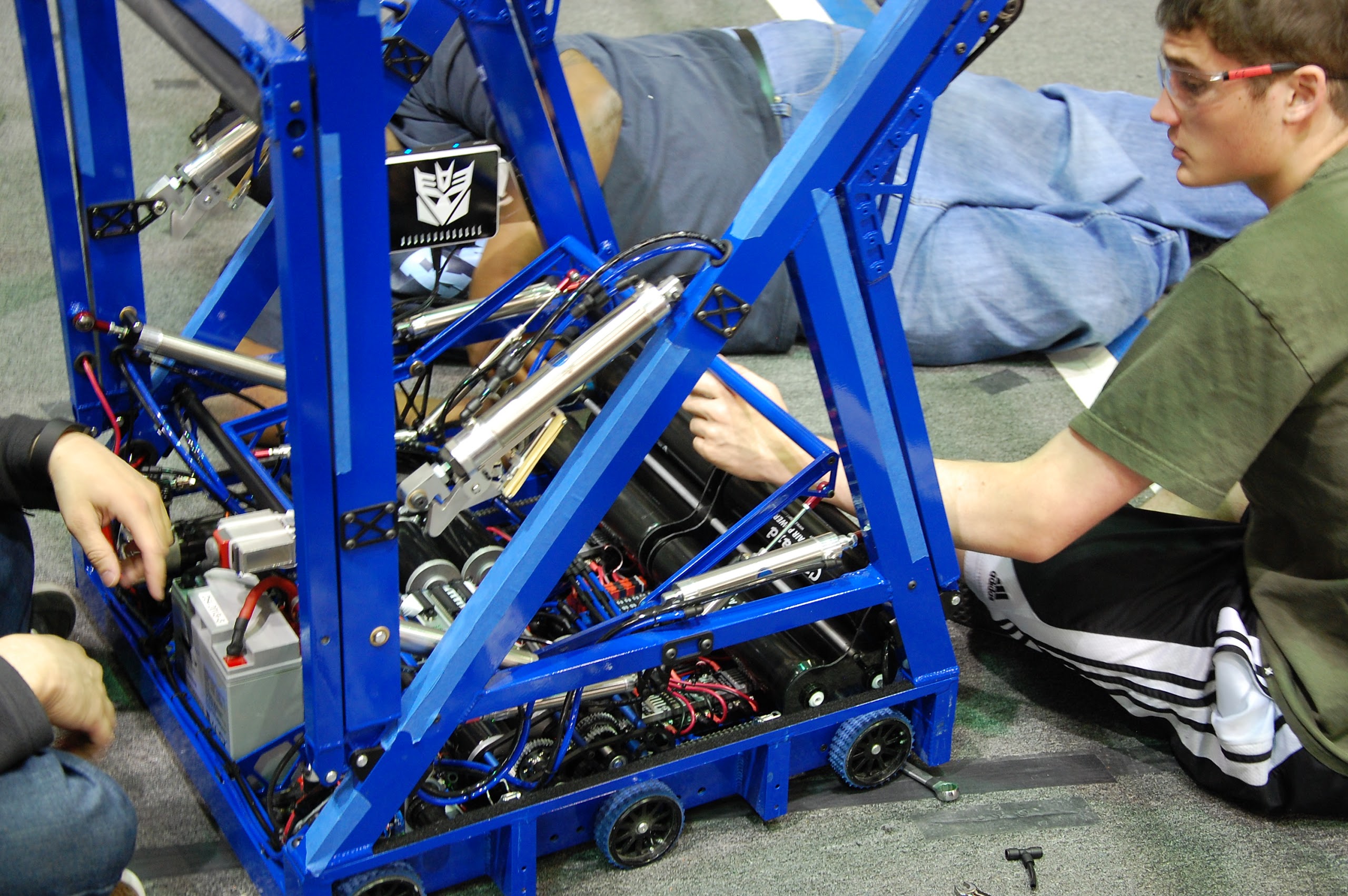

A couple of members worked on mounting and wiring the router onto the robot. This router is the primary means of communication between the driver station and the robot. Members working on the sponsor panels took a break cutting out the stickers for the Decepticon insignia.

Construction

The team also worked on finishing the red bumpers for the robot and one of the blue bumpers. A couple other students created labels of the team’s sponsors for the side panels. The team has decided to put sponsor names on the side panels of both robots, and so far the competition panels have been completed.

The team also worked on replacing the shifter plates for the practice robot’s drivebase.

Flier

The graphics design team continued work on developing a flier to showcase the robot.

Action Items

- Finish sponsor panels for practice robot with Jeremy, Mani and Travis

- Prepare for the photo shoot

- Finish both competition and practice robots

- Programming the hot goal sensors with Tom and Brandon

- Work on the flier and T-shirt with Kevin

Day 46: Bag and Tag

by Chris Powers ’15

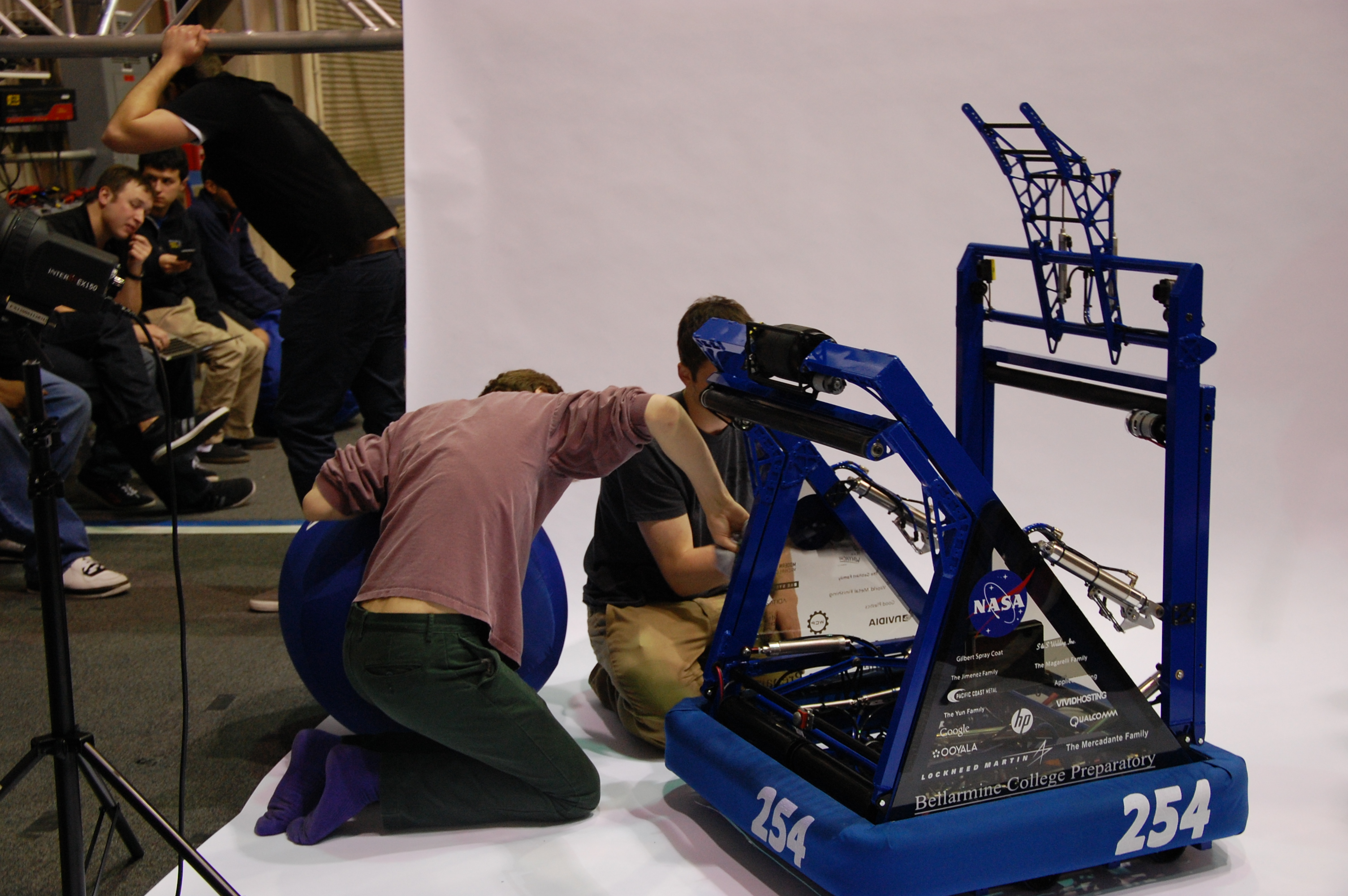

Photo Shoot

Today was bag and tag day, so not much machining or robot work occurred. Most of the team worked on taking multiple shots of the finished competition robot, which was placed in a studio area on one half of the field. The team took photos at multiple angles with different lighting and game objects.

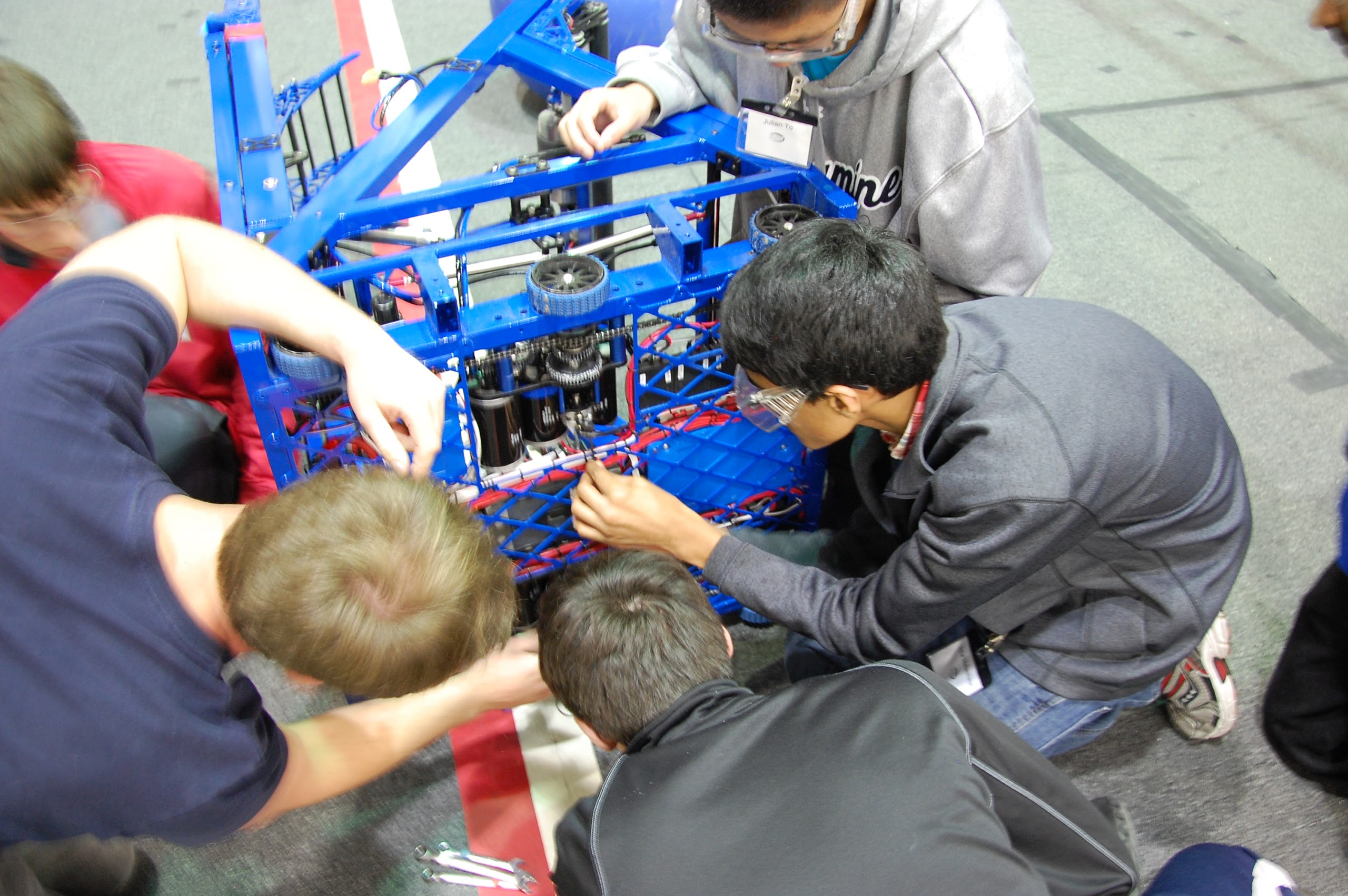

Practice Bot

Other team members worked on improving the practice robot on the other side of the field. A belt broke on the robot, so team members repaired it.

Graphic Design

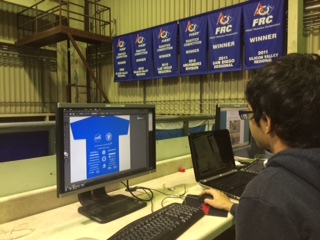

The graphic design team continued working on the T-shirt designs. A design is not yet finalized.

Bag and Tag

The robot was bagged and tagged at approximately 9:30, concluding six weeks of intense fun and work and ushering in six weeks of regional competition preparation.

Action Items

- Rest day tomorrow- no build.

- Continue working on T-shirt and flier with Kevin.

- Continue working on practice robot.

Day 47: Rest!

Everyone took the day off today as a reward for all the hard work we put in over the past 6 weeks to get the robot bagged!

Day 48: Organization and Writing

by Matt MacDonald ’17

Assembly

Today, students worked on replumbing the locking pistons on the practice robot to make sure it functions to the best of its ability.

Organization

The team also organized the Box of Pat. Students cleaned out the case and made sure the parts inside the shelves were placed in proper order. The parts were put in different compartments that would allow students to find what they need easily.

Pit Display

The team also improved pit lighting controls. A mentor worked on the Arduino code that can be used to control the lights and students also worked on the website that controls the lights.

Writing

Students also prepared for the Chairman’s award presentation.They also wrote about the team’s outreach events and its basic information to display at tournaments.

Action Items

- Continue driver practice

- Reorganize lab

- Finish the pit display

- Finish Chairman’s presentation

Day 49: Chairman’s and Driver Practice

Chairman’s Award

Today students brainstormed and storyboarded the 2014 Chairman’s Award Video. This video is required with all Chairman’s entries and the winning team’s video is shown at the end of each tournament. Also, another group continued work no a Chairman’s Powerpoint template that will be used during the presentation. Finally, the three presenters continued to flush out the script and got to practice 2 times before mentors and get their thoughts on what information should be added.

Driver Practice

Drivers worked on receiving the ball from the human player without utilizing the rear intake. They rigorously practiced pinning the ball to the side wall to force the ball into the intake, in an attempt to lessen ball transfer time.

Field Construction

Students finalized the field construction today by adding the human player boundaries on the side of the field. This boundary tell the human players exactly where they are allowed to stand, which help make driver practice more realistic.

Programming

Programmers were brainstorming ideas for a possible Team 254 mobile app that will feature all the web products 254 has to offer. This includes the hours tracking systems, various resources (handbook, identity standards, tutorials), and the home page with a simple calendar.

Graphic Design

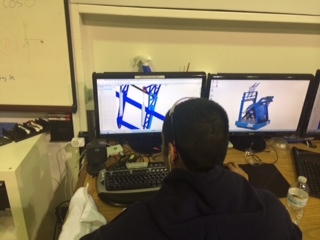

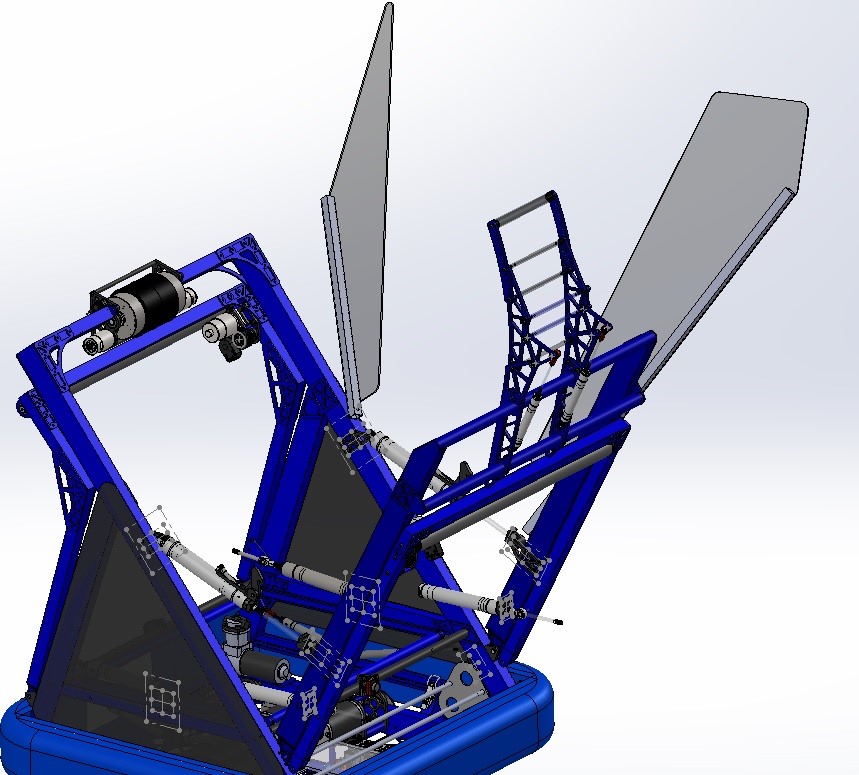

Students continued to program the team’s new pit display. Others were adding sponsors to the 2014 T-shirt. Students were also rendering specific assemblies in of the CAD for use in the Technical Binder. These renders all people to more easily see the functions of each mechanism of the robot and they all work independently and then come together into one finished product.

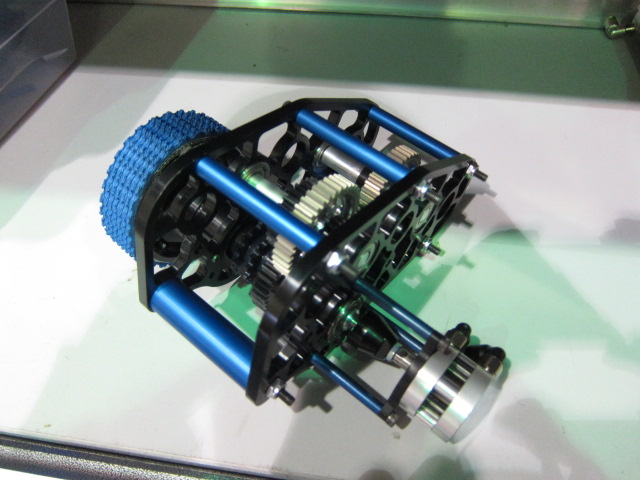

Assembly

Students began to assemble the 5th, display gearbox. All the parts have been found and the gearbox simply needs to be assembled. In addition to being a useful display piece to explain the 3-CIM shifting gearboxes we are using this year, this will also serve as a spare gearbox we can use or at least scrap for parts if something breaks at competition.

Miscellaneous

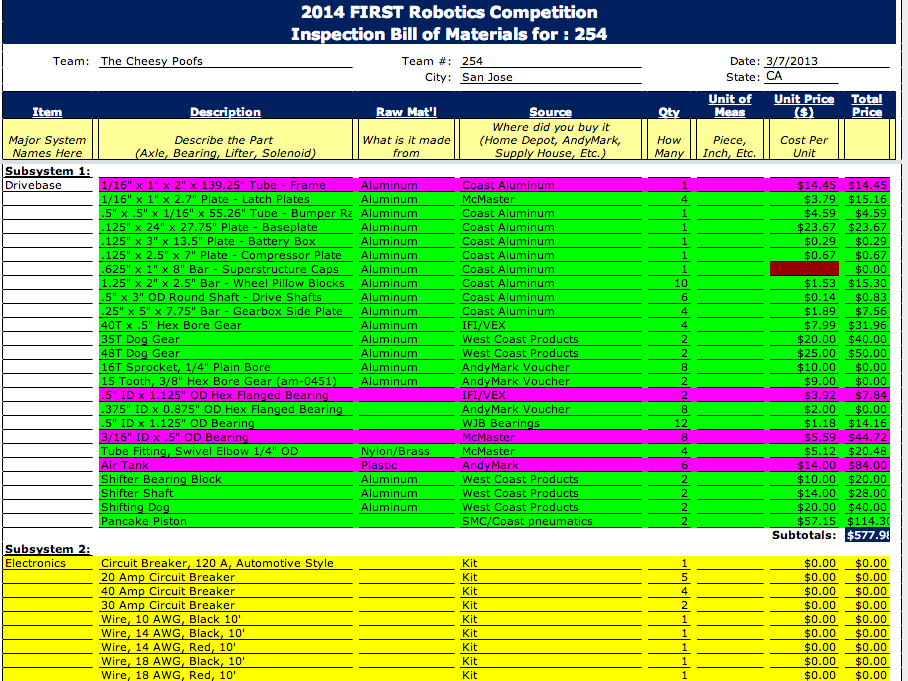

Students continued to work on the Bill of Materials (BOM) by using the CAD and Parts Management System to figure out what parts we ordered and what actually made it onto the robot. Currently the drivetrain is finished and electronics and intakes subsystems are in progress.

Work on the release video made significant progress. A first draft was made featuring “Light em Up” with shots of the robot and the double-3-ball-autonomous. This draft can be viewed at this link: //video.team254.com/watch/hhZjlzazqf4JTKXlP62-pq2Q3vi1pTBQ

As this is only a draft and not the final copy, don’t share this yet!

Action Items

- Finish assembly of demo gearbox

- Continue working on the BOM

- Continue driver practice

- Continue improving Chairman’s Script

- Finalize Chairman’s Video storyboard

- Begin work on compiling the technical binder

- Begin work on compiling the Chairman’s binder

- Create Chairman’s PowerPoint

- Decide what spare parts need to be made, including for demo

- CNC the new rear VEX bump sensor mount

- CNC new wheel hubs

Day 50: More Pre-Comp Preparations

Driver Practice

Today, students continued to practice driving the robot on the field. Obstacles were set up on the field earlier in the day to test the new drivers’ capabilities.Later, students practiced driving with other students in the human player boundaries feeding the robot balls.

Demo Gearbox

Students finished assembling the display gearbox.

Chairman’s Award

Students added pictures to the Chairman’s Award PowerPoint. Finding the right pictures is a big process in creating the presentation.

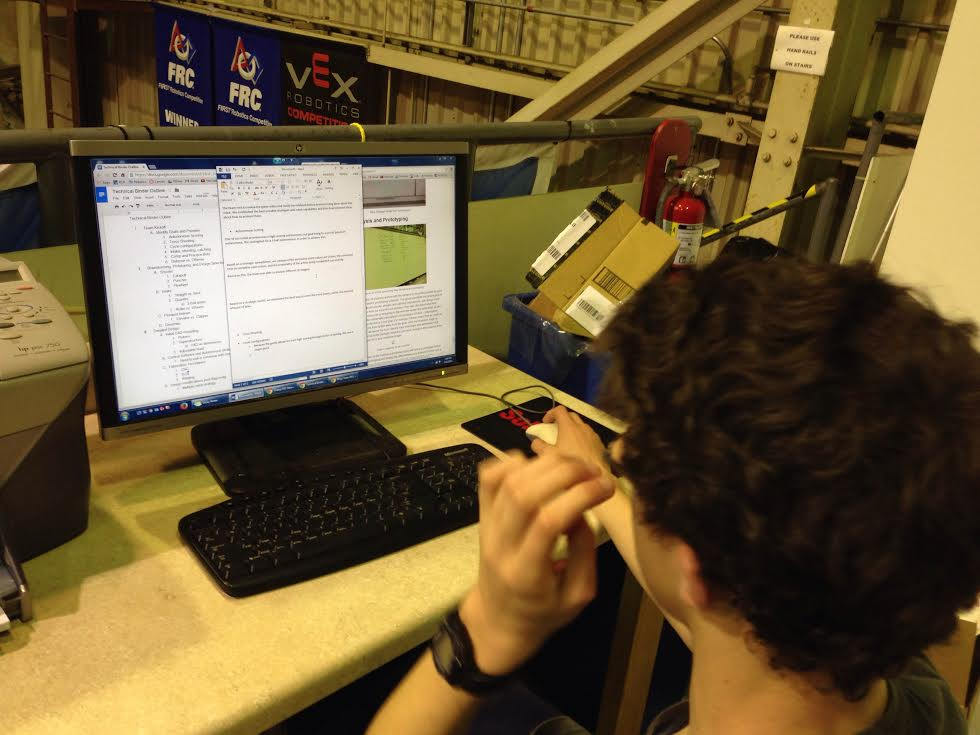

Technical Binder

Students worked on updating the technical binder for the Chairman’s award. This binder contains all of the specifications for the robot.

Team Flyer

Students continued to work on drafting the Team Flyer. The flyer is an easy way toinform other teams and passersby during tournaments about the robot and theteam. This is a simplified version of the technical binder. However, after some further discussions we decided to try remaking the flyer with a shot of the robot with the intakes opened. That photo is being photo shopped now and will be used soon.

Programming

Programmers continued to work on the pit display. Currently, they are working on fixing the team page.

Field Optimization

Students started to improve the field by configuring the scoring lights. These lights indicate whether the robots are in autonomous or in tele-op mode. This will help simulate a real game for driver practice.

Assembly

Students began constructing an intake on-top of the Overkill Practice Drive-base made of wood for a drivers to face-off against.

Bill of Materials

Students continued working on the Bill of Materials. Today they finished recording data for the intake, electronics, and are currently working on the hood.

Action Items

- Continue working on the BOM

- Continue driver practice

- Continue improving Chairman’s Script

- Finalize Chairman’s Video storyboard

- Improve Chairman’s PowerPoint

- CNC the new rear VEX bump sensor mount

- Finalize the Team Flyer

- CNC new wheel hubs

Day 53: Rain Won’t Stop Our Excitement and Preparation for Madera

Co-Authored by Tyler Cuff and Robert Lim

Testing

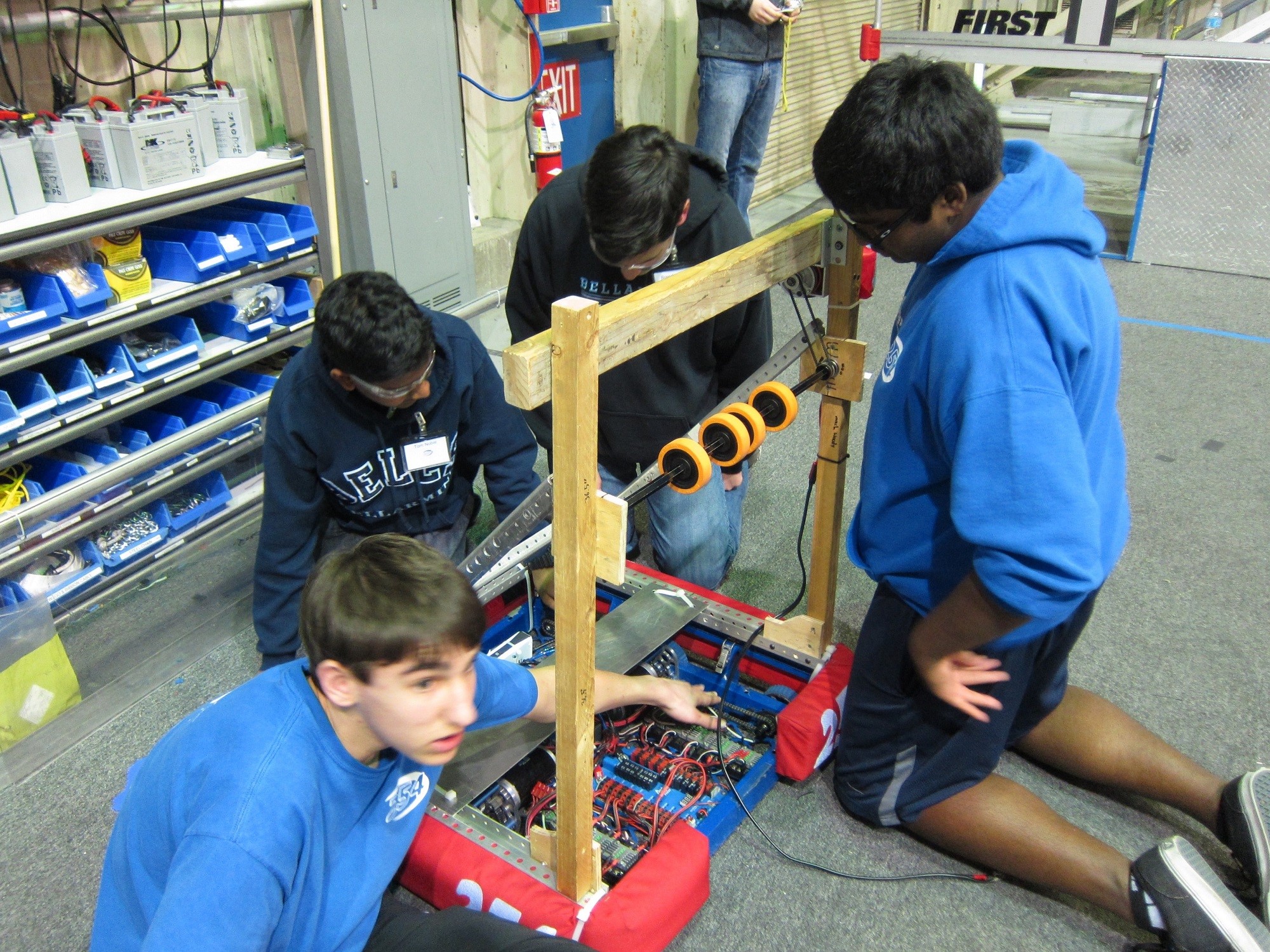

The day began with students and the drive team practicing and troubleshooting the robot. The drive team traversed the field and practicing scoring goals as quickly as possible.

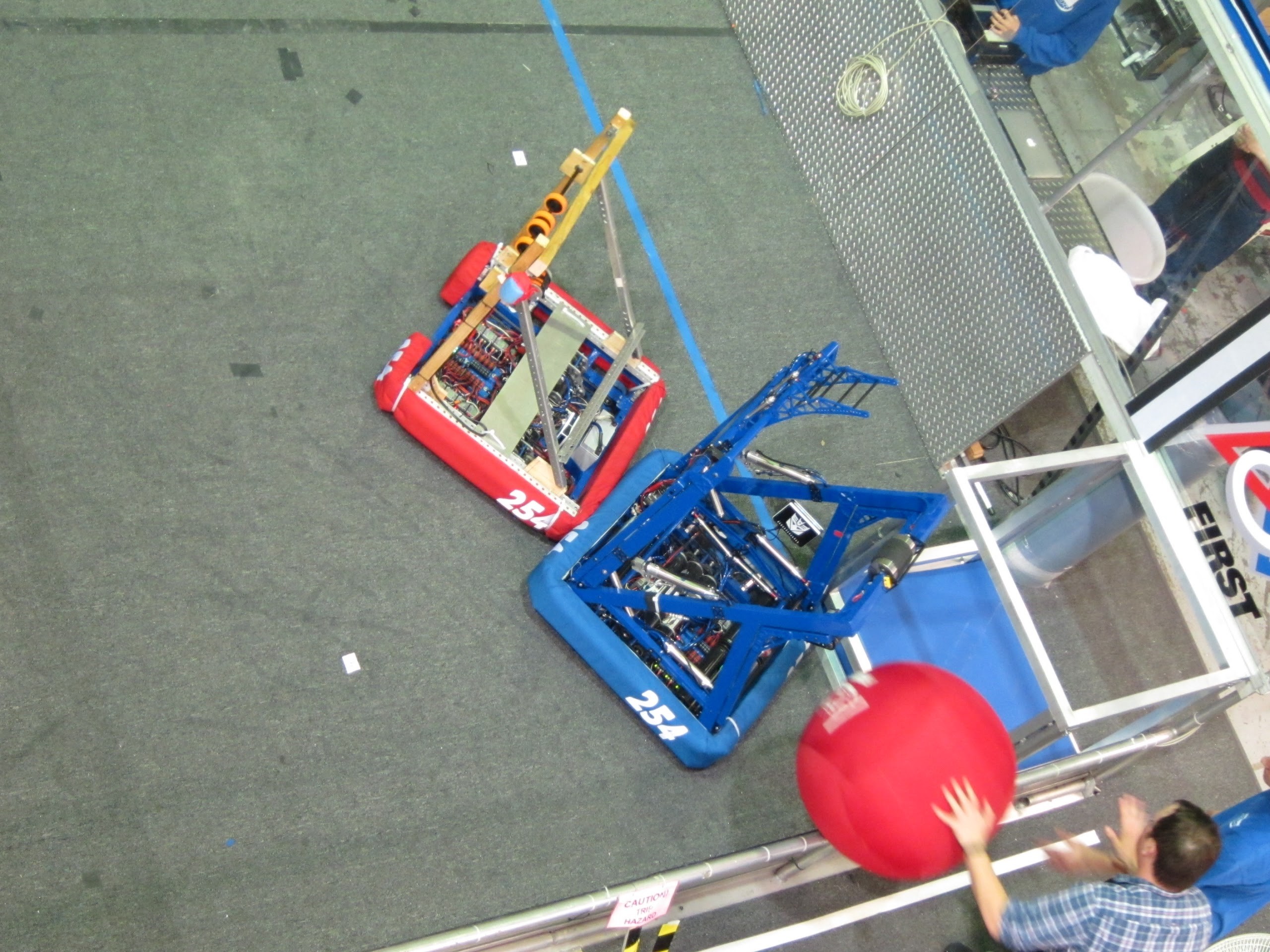

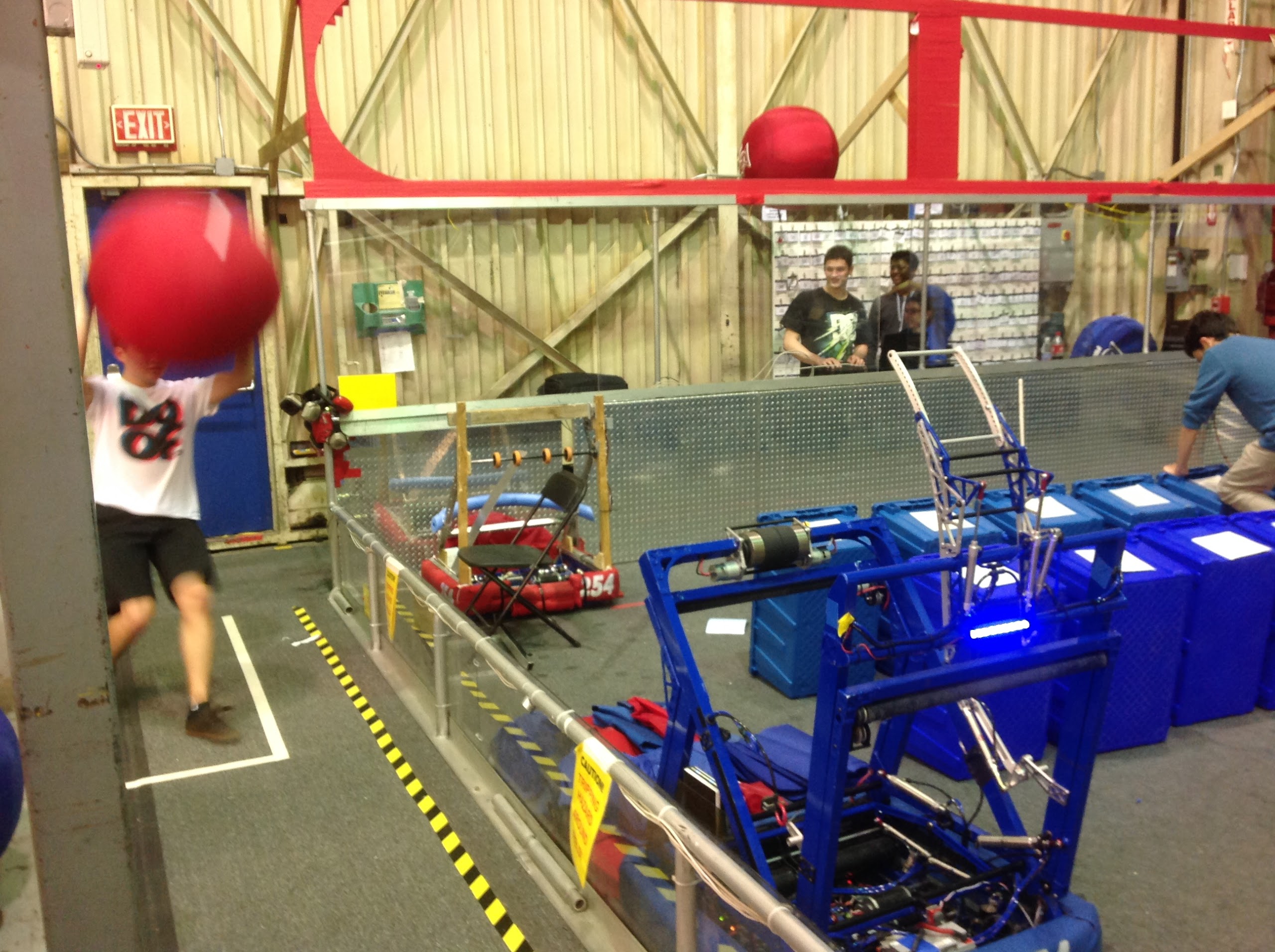

After Skystalker, the surrogate opponent robot, was up and running, the driver practiced scoring with its uncooperative counterpart playing defense (see image below) This accustomed the driver to moving around the field with an opposing robot attempting to block movement and impede shooting.

Electronics and Wiring

During a half hour window of robot downtime, students attended to other projects. Students installed lighting in the battery cart and added a vinyl finish. Meanwhile several other students worked on improving the wiring of Skystalker by loosening its chain for the drive train.

Parts Organization

The main piece of organization was the continued efforts on the Bill of Materials, pronounced Bom in airports, needed for Madera. The BOM will describe a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts and the quantities of each needed to manufacture an end product).

CAD

Several student worked on completing the SolidWorks CAD tutorial to improve their practical knowledge of CAD. The majority of them created sketches while others put together assemblies.

Awards

A team worked on the Chairman’s Award presentation PowerPoint for the upcoming Madera tournament in March. A leader began to finalize the script. Remember that our Chairman’s presentation is confidential and should NOT be shared or discussed outside of the team. Another team worked on the Media and Technology Innovation Award that is due tomorrow. Its content was finalized with approval throughout the team and the graphic design and layout format will be finished tonight.

Design

Upstairs, students had a discussion on how to improve the robot and what will definitely will happen. We will be adding the side panels for giving proper recognition to all our amazing sponsors. Two suggestions were adding triangular plates onto the side of the robot to assist in catching, and another involved the addition of surgical tubing to strengthen the catcher.

Miscellaneous

The lab received a new printer, scanner/copier, and 24″ monitors. With the recent rain, a few students noticed a small leak in roof on the east side of the lab. The team also played some pick-up volleyball with an exercise ball and the truss.

Action Items

- Driver practice

- Build control board

- Machine, anodized, and then remachined

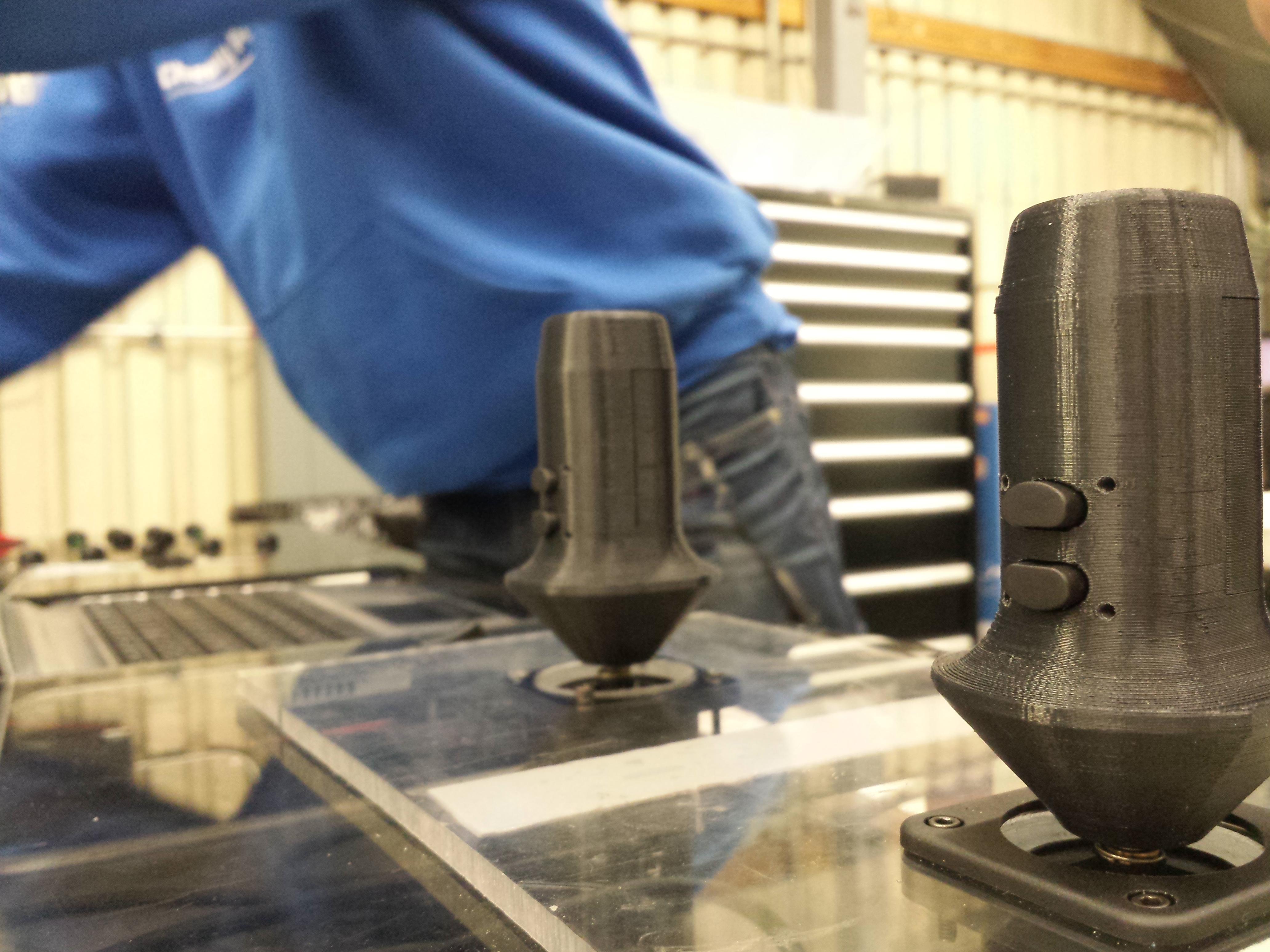

- Print handles

- Make control board standoffs

- Prototype catcher

- New accumulator standoffs

- Drill Grommet holes on spare intake

- Set up us up the BOM

- Film fly through scene

- Technical Binder

- Wire Batteries

- Test Batteries

- new pinniped standoffs

- cut, weld, and powder

- Mentor Castle prep

- Autonomous vision targets and lights

- Make wheels

- Redesign catcher pistons

Day 54: More Testing

by Ian Chiu and Tyler Cuff

Testing

At the NASA lab, the drivers have begun to practicing to operate the robot for the upcoming tournament at Waterloo. One group of students used a defensive robot to block Barrage, while the other group used Barrage to score.

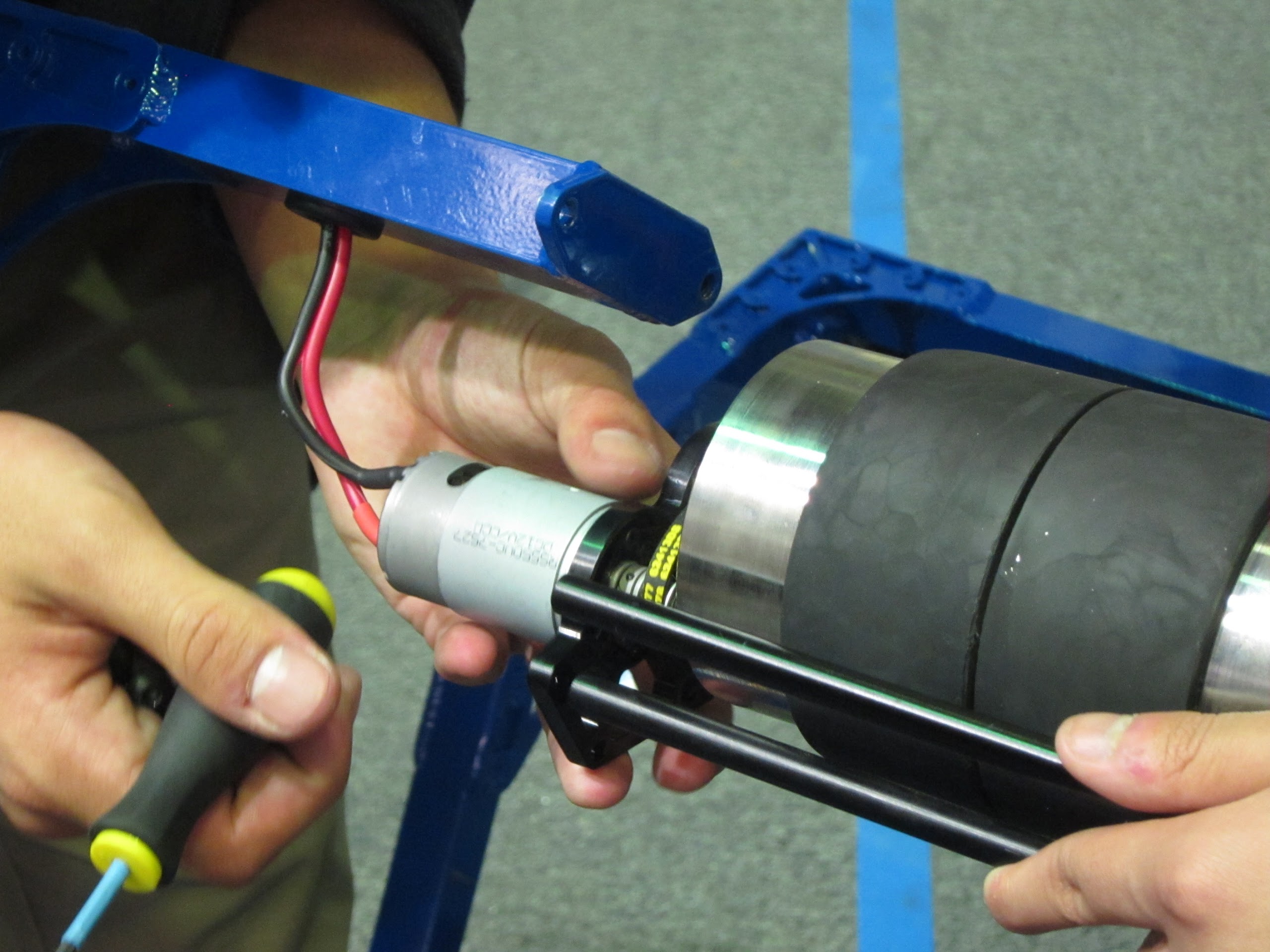

Construction

The drive team decided to create a drill board to hold their drills so they could keep all their drills in one place, allowing them to keep the lab a much more organized place.

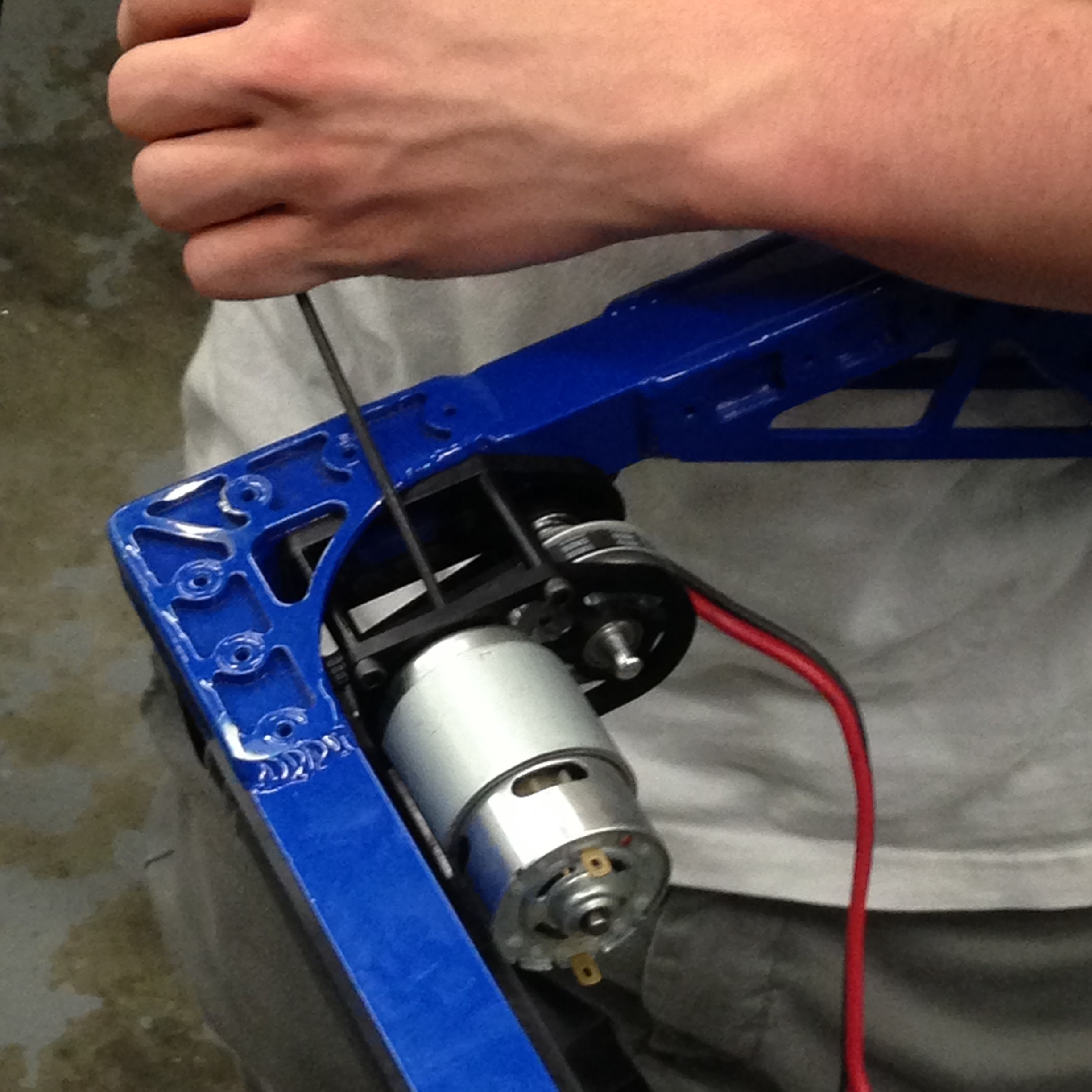

The drive team had to get off the field when the belt on Barrage broke. They removed the flywheel so that they could replace the belt.

Several members began treading the wheels for the robot, beginning by putting the treads into the tread gauge.

Awards

Some of the mentors and members were working on the screen together to create a successful scene to film for the Chairman’s Video. Soon, they will edit the filmed material to create a final product to submit for the Chairman’s Video. A few members also worked on the Media and Technology submission

Action Items

- Clean up – Everyone

- Driver Practice – Pat/Kevin/EJ

- Film the catcher – See Collin if you want to help

- Build Control Board – Cory

- Prototype catcher

- New accumulator standoffs

- Set up the BOM – Ryan/Louis/Clay/Vidur

- Film flythrough scene – Alex

- Wire batteries – Mani

- Test batteries – Pat

- New pinniped standoffs: cut, weld, powder

- Mentor castle prep – Mani

- Automate vision targets and lights – Bruno

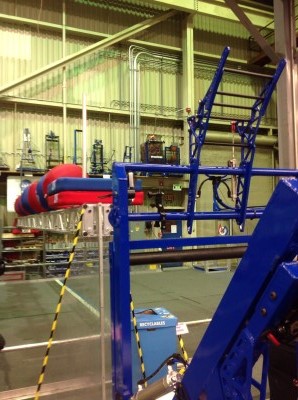

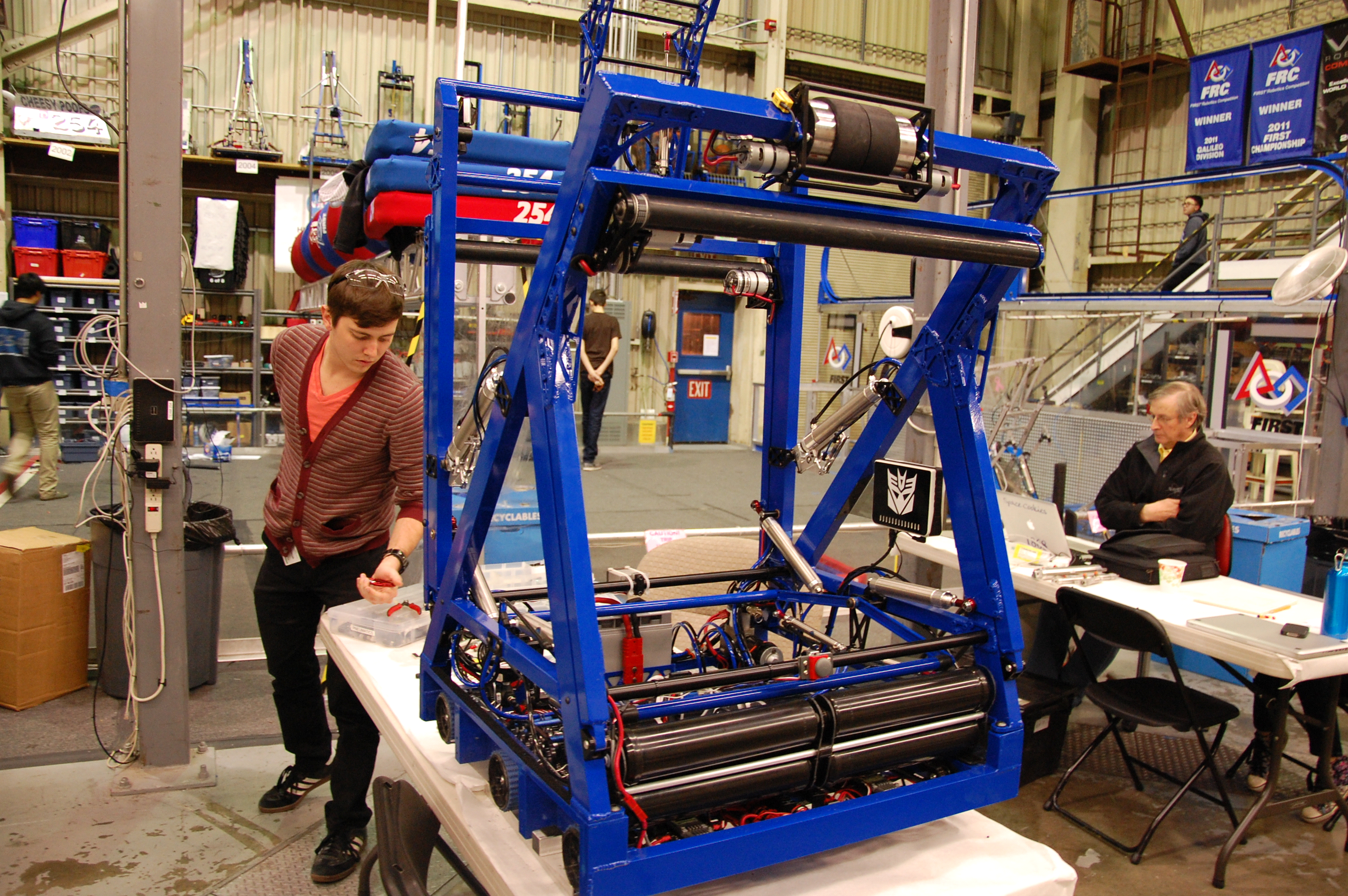

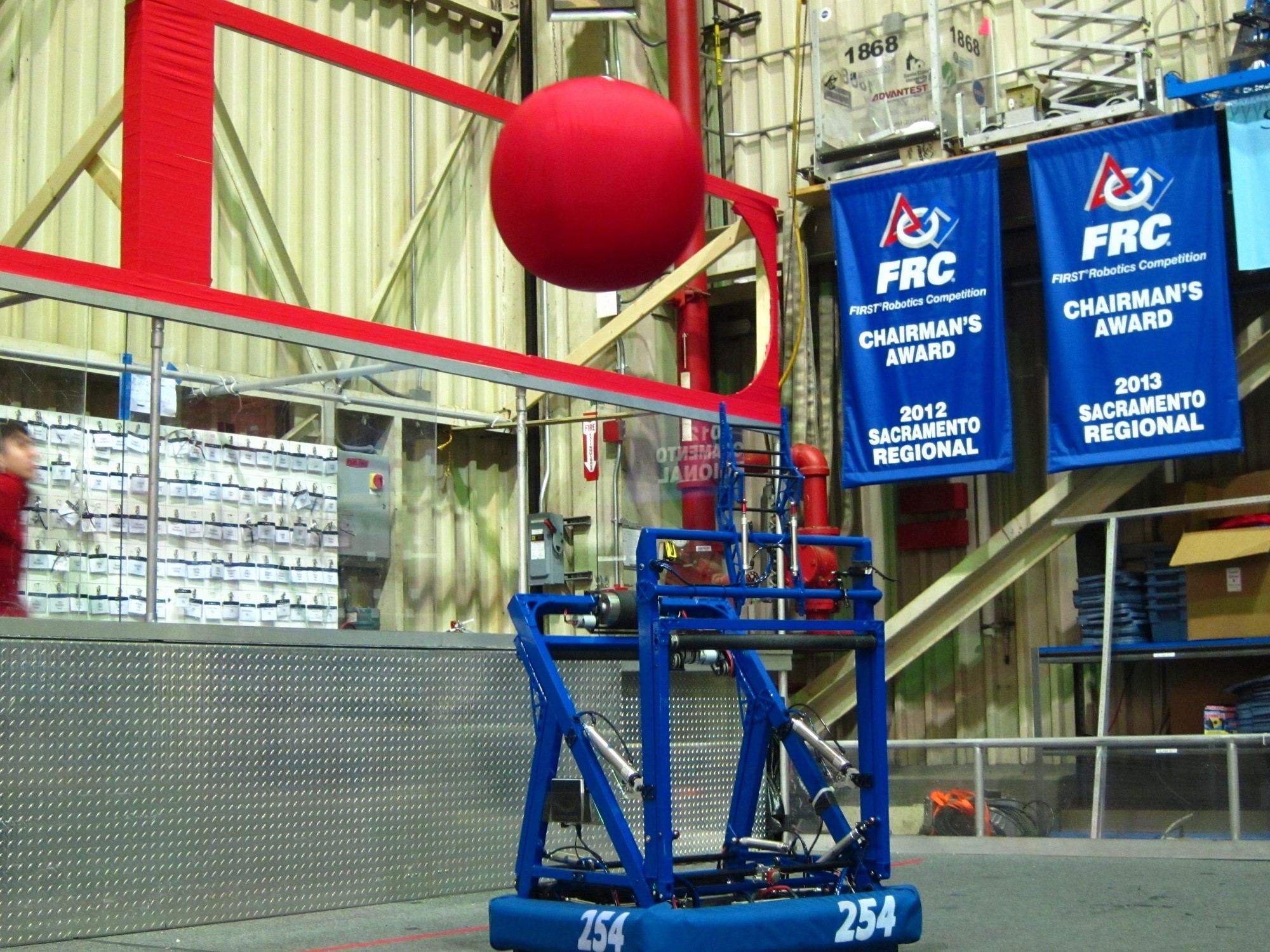

Team 254 Presents: Barrage

Team 254, NASA Ames Robotics “The Cheesy Poofs”, proudly presents our 2014 robot: Barrage.

Barrage will compete at the Central Valley Regional, Waterloo Regional, Silicon Valley Regional, and FIRST Championship.

Team 254 is sponsored by NASA Ames Research Center, Lockheed Martin, The Mercadante Family, Ooyala, TR Manufacturing, Qualcomm, HP, West Coast Products, The Magarelli Family, The Yun Family, Google, Modern Machine, The Gebhart Family, Aditazz, Cisco Meraki, Vivid-Hosting, Nvidia, BAE Systems, Gilbert Spray Coat, Pacific Coast Metal, S&S Welding, Good Plastics, Team Whyachi, Applied Welding, World Metal Finishing, The Jimenez Family, Hy-Tech Plating, and Bellarmine College Preparatory.

Day 58: Competition Homestretch

by Dan Ngo ’17

Competition Preparation

Driver practice continued today in preparation for Madera, with the same format as before. One driver controlled with practice Barrage, while the other driver played defense with Skystalker.

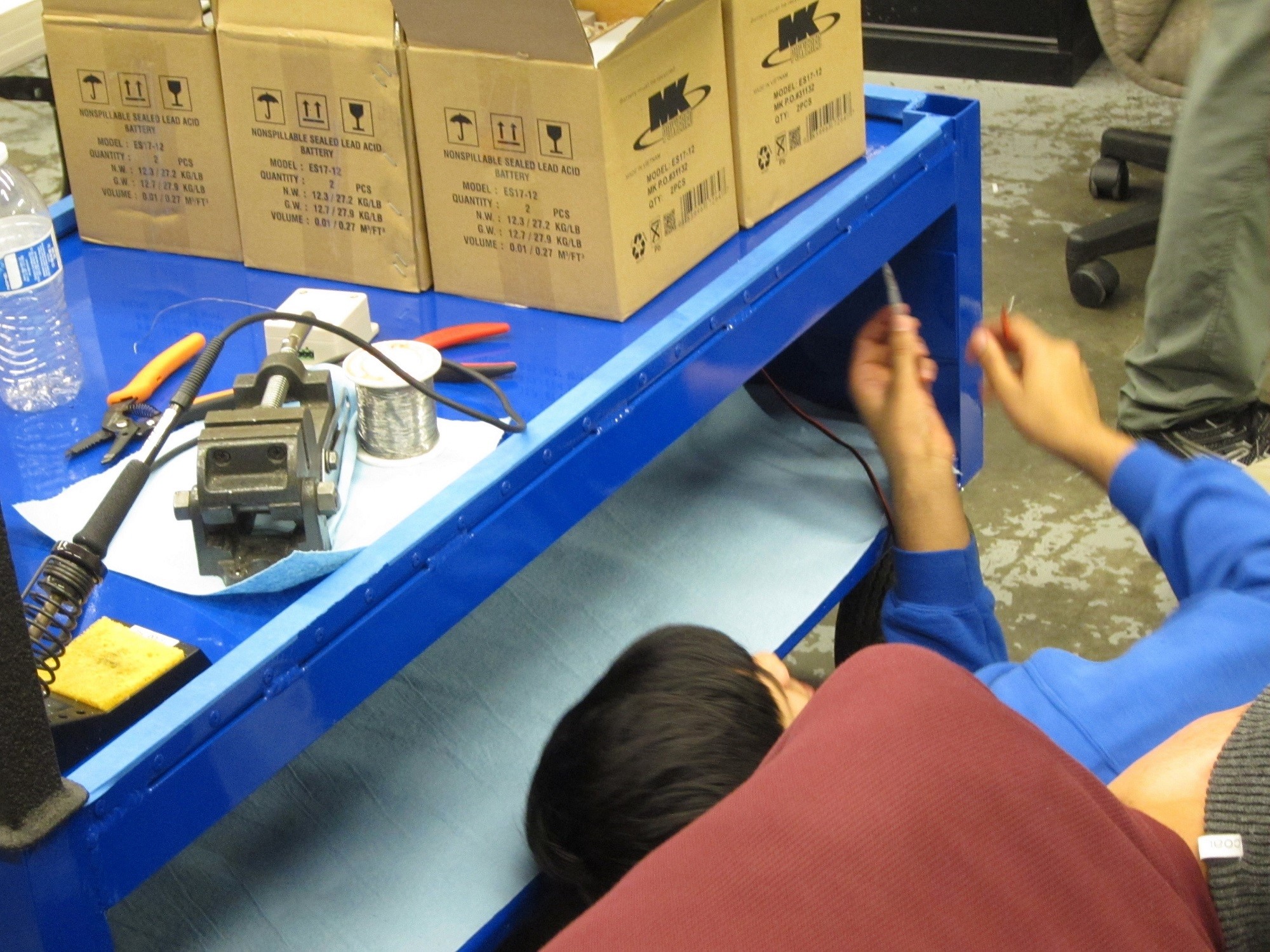

Members worked on attaching power cables to fresh batteries, to be used as soon as possible.

In addition, competition materials were packed, including the custom-made drill holder, various tools, and spare parts.

Awards

Today, the team also worked on crucial parts of the Chairman’s Award, including the binder, video, and presentation. Progress was made on the binder’s graphic design, and finished in time for the competition. The video was filmed beforehand at school, and one of the members will work on the editing. The presenters practiced the Chairman’s presentation to get feedback from the mentors.

Pit Display

The video team crammed work on the competition pit display on the 20″ screen. Next week the team will receive a 42″ monitor.

Action Items

- Technical BinderBill of MaterialsChairman’s Binder: History, Images

- Chairman’s Video EditingDriver PracticePrepping BatteriesPacking Materials

Day 59: Pre-Madera T-1

by Brendan Conaway ’17

Testing

Today the team did some driver training for Madera by driving around the field, scoring some goals, and practicing passing over the truss. Skystalker functioned as an opponent bot for driver practice. The air was refilled on Barrage several times and the wiring was fixed once or twice.

Awards

A few of the members worked on the Chairman’s Award binder. The presentation is done and awaits finishing touches. The presenters will be the head of competition (human megaphone), the programming director, and the director of outreach. It is highly encouraged to nag them to practice the presentation. Team members should know who they all are.

Madera

Madera is this weekend! There was a shipment of supplies that came in, and it was packed into the black boxes that will be brought to Madera. Those going will be leaving on Friday, March 7th, right after school and returning on March 9th later in the evening. Be ready for a 2 hour drive. Let’s win this!!

Pit AV

Some students worked on making the pit display for use at competitions. Other students worked on the touchscreen display to be used in the pit.

Pre-Waterloo Day 2

by Ford Hooper ’17 and Brendan Conaway ’17

VEX State Championships

Since much of the team is busy preparing for the VEX state championships, the number of team members attending was below average today. Even so, the team was able to make critical improvements in working towards becoming prepared for the Waterloo regional.

Technical Binder

Today, most of the members at the NASA lab were focused on reconstructing the technical binder. This binder is the summary of the robot and the steps the team has taken to design it. The binder is a large part of the judges’ decision on the winners of the Quality Award.

CAD

Other members were working on designing a new CAD for the hood piece of the robot.

Post Madera

Several members wrote 7 articles about the team’s experience at the Madera Robotics Tournament this past weekend.

Action Items

Pre-Waterloo Day 4

by Jose Moreno ’17

Machining

Today several students were machining several tubes and rods to be made into multiple extra intakes.

Most of today, the team focused on making a new hood extender, which is now able to reach the third bolt hold, and extends an extra inch for a new shot angle.

Writing

Today students edited the Madera articles for the Carillon Online News Source, the Cardinal Newspaper, the Bellarmine Website, and others. They also edited the script for the Chairman’s Award Video.

Pre-SVR Day 4: Preparation

by Nathan Duong ’16 and Josh Fluegemann ’17

Pit Display

The programmers of the team worked on the pit display; they primarily sought to improve the quality of the display through cleaning up the HTML and CSS of the web application. Today, they added lightbox capabilities to the web box.

Pit Lights

In addition, notches were made in the pit lights tubing for soldering.

Chairman’s Binder

Research is being done for the chairman’s binder; members are compiling a list the alumni’s colleges.

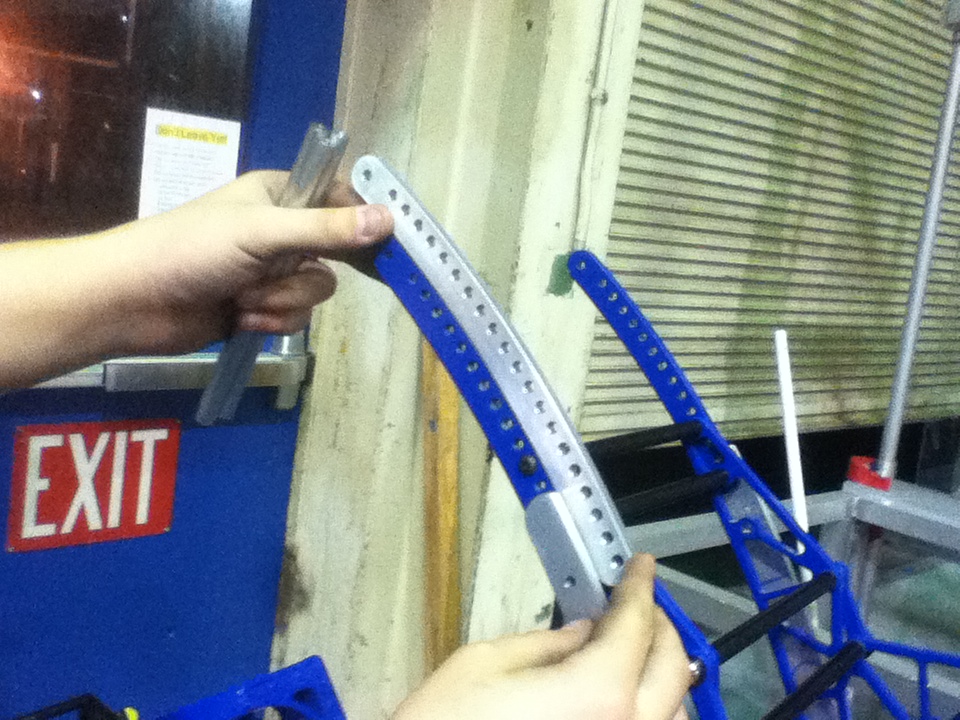

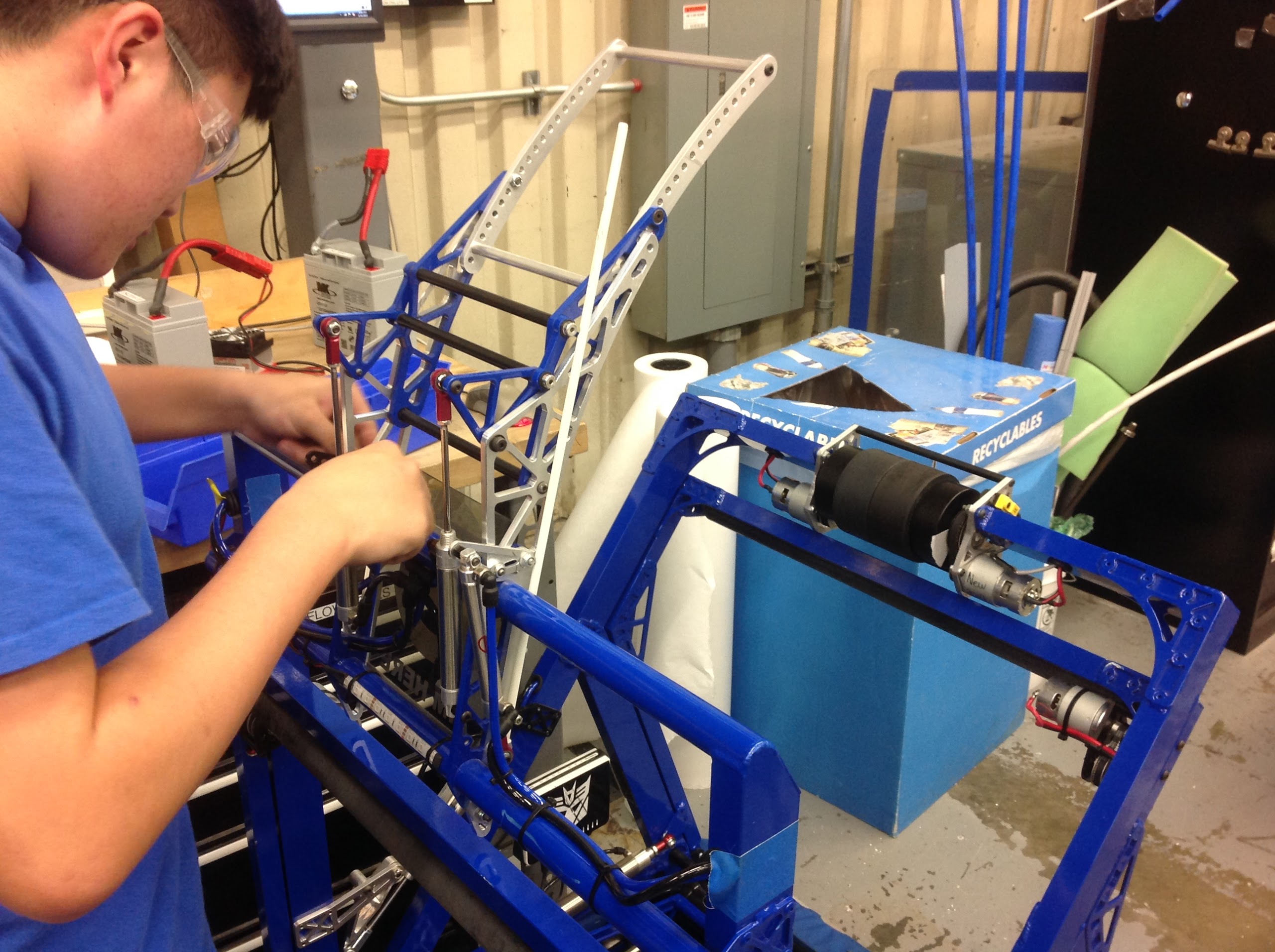

Intake

The intake is being put back together after individual parts were sent back from Waterloo. To do so, the plate, motor, and intake roller were reconnected with the skeleton of the intake.

Action Items

- Manufacture above parts and install on robot (all McMaster parts required have arrived) – Travis/ Colin

- Finish shooter redesign (SDP and VEX parts are on order) – Paul

- Prepare sponsor welcome packets for when sponsors come to SVR – Stephen

- Work on pit-lights and finish assembly – Ken

- Cut/install vinyl labels on hinged-lid totes (light blue, dark blue and black all need new vinyl) – Travis/Mani

- Test LCD mounts – test installation on trussing – Travis/Ken

- Finalize video banner – Ryan

- Improve Pit Display and test with new monitors and projector – Ryan

- Design projector mount for video banner – Travis

- Finalize video banner mount – Travis

- Fix/create hand sanitizer mount – Mani

- Design/build new bumper hangers for truss – Travis/Mani

- Improve technical binder – Andrew

- Improve Chairman’s binder – Jeremy/Andrew

- Improve Chairman’s video – Jeremy/ Kevin

- Re-print all binders and sponsor packets with correct bleeds and page splits – Jeremy

Pre-SVR Day 7

by Samuel Buxton ’16

Scrimmage

Today was an eventful day at the lab. In preparation for the SVR (Silicon Valley Regional) our drivers trained against some of the best teams in the region, including 1868, 971, 192. and 776.

SVR Prep

Upstairs the team fixed “Barrage’s” intake, and a separate project using some colorful LEDs light up the pit.

The “Minion Project” reached a milestone with the completion of a mini mascot costume, which was unveiled this weekend. The costume is based on the original “Cheesy Poof” costume from South Park.

Work continued for the pit display and drivers got the opportunity to sharpen their skills for the upcoming tournament.

Pre-SVR Day 8

by Brendan Farrer ’17

This lab day was mainly dedicated to preparing for the SVR tournament and finishing up the Chairman’s binder and Technical binder.

Pit Display

The final touches were made to the pit display, including fixing the remote light controls and adding a carousel effect for when it is inactive. While programmers edited the code, other members finished the content for the display, such as re-writing the technical page.

Machining

To assist in collaborative gameplay, a polycarb backing was created to mount on the hood. This allows the human players from other teams to inbound more accurately.

Practicing

To continue driver and human player practice, the pinniped pistons were added back to the robot and the modifications were finished to the catching system. These modifications allow the robot to catch balls thrown by a human player without opening the intake. Several team members were also trained to be human partners for the robot.

Writing

Several team members contributed to the completion of the Tech Binder along with the Chairman’s Award Binder. Although the majority of the work was completed, they continue to format and edit the content.

SVR Packing

With only two days until SVR, the necessary tools and materials for the competition were prepared to be packaged for travel. Mentors and students went through travel crates, re-labeling and organizing for the optimal set up.

Pre-STL Day 1: Going Forward

by Dan Ngo ’17

Tasks

Today, the team started with a discussion about our performance in SVR, between all of the mentors and members at the lab. During that, the team addressed most of the issues that the robot had during the tournament, which mainly consisted of getting stuck by T-boning from an opponent, which would cause too much friction escape, as well as improving and testing new autonomous, to cover new possibilities and better reliability. The other issues include general fixing, testing, and making of parts and possible ways to improve our alliances.

Programming

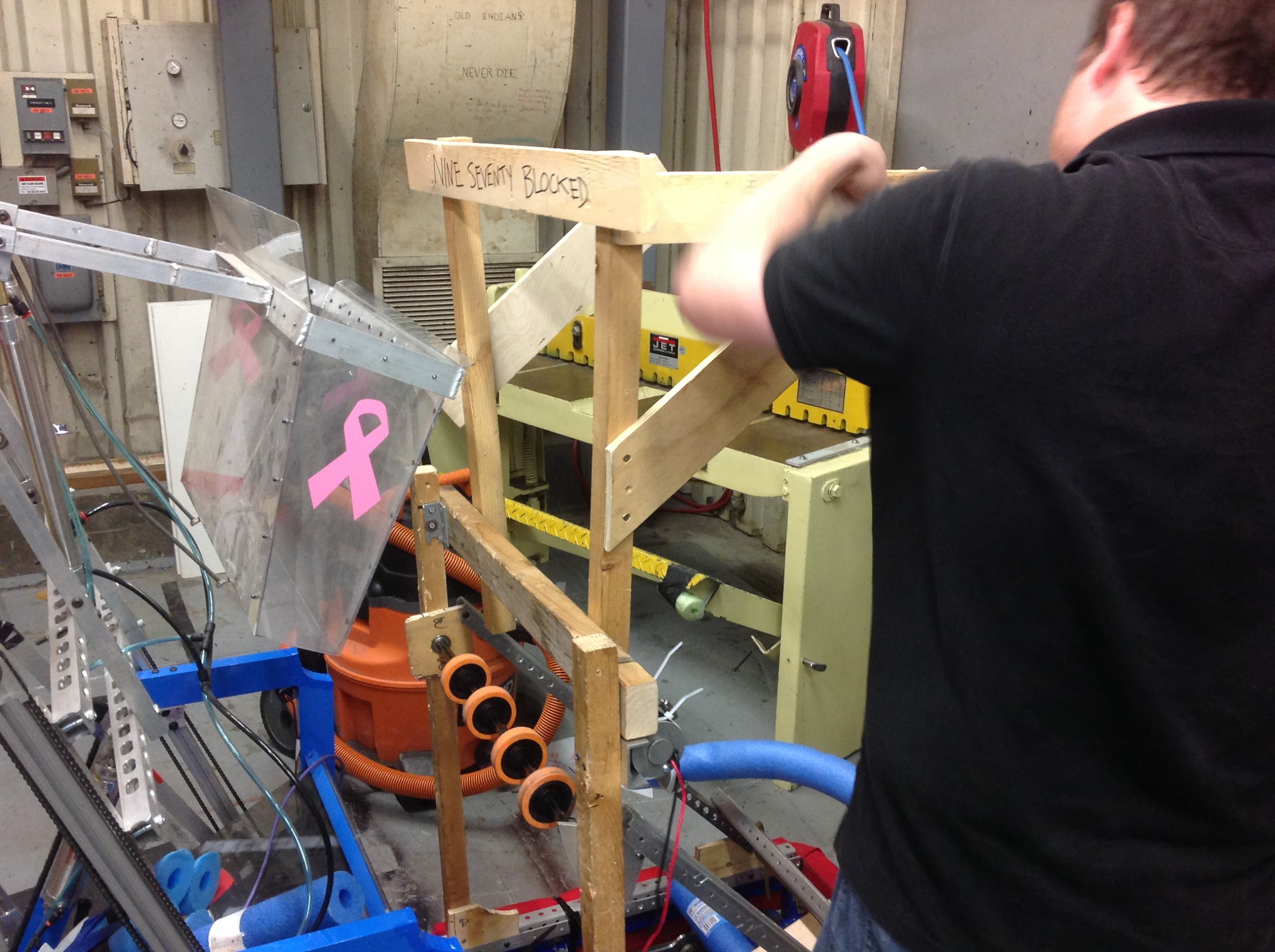

During the present team meeting, concerns were raised about possible robots blocking the goal autonomous, so it was decided that another autonomous would be made to suit this situation, shooting immediately instead of waiting for a hot goal. Before we could do this, however, Skystalker had to be fixed, with the router unable to connect to our computers.

Maintenance

Thus, Skystalker had to be fixed up and made taller to test the new autonomous that accounted for goal blocking. For practice, the practice Barrage was also updated and fixed, to catch it up with the competition Barrage at SVR. Then autonomous testing began.

The team additionally had to unpack and reorganize all the parts brought back from SVR, as well as general reorganization of the shelves.

With a large amount of untested batteries, the team also decided to test all of them in preparation for Worlds. This was done by hooking the batteries up to a computer, drawing current, and and calculating the condition of the battery once the current drops in value. Additionally, leads were added to new batteries.

Public Relations

Returning from SVR, the team flyer had to be updated to be current with the SVR version of Barrage. The technical binder also had discrepancies and errors to be fixed.

Action Items

- Continue autonomous testing

- Continue upgrading Skystalker

- Continue testing batteries

- Build new bumpers

- See picture and/or whiteboard

Pre-STL Day 2: Robot Repairs

by: Brenden Farrer

Today at the lab, other FIRST teams, such as Spartan Robotics, came to practice with our field. The primary focus was on fixing the practice robot and Skystalker to continue driver practice with the other teams.

Skystalker

A “hat” was built for Skystalker that allows it to block and carry a ball. The wheels were retreaded, as the previous ones have worn down. Hopefully these new defense capabilities will provide more practice for the drive team.

Practice Robot

Today students began discussion and planning of future projects. However, a second ball settler was attached to reduce the motion of inbounded or caught balls to increase accuracy when shooting. Adding a powerslide wheel was discussed, no changes were implemented today.

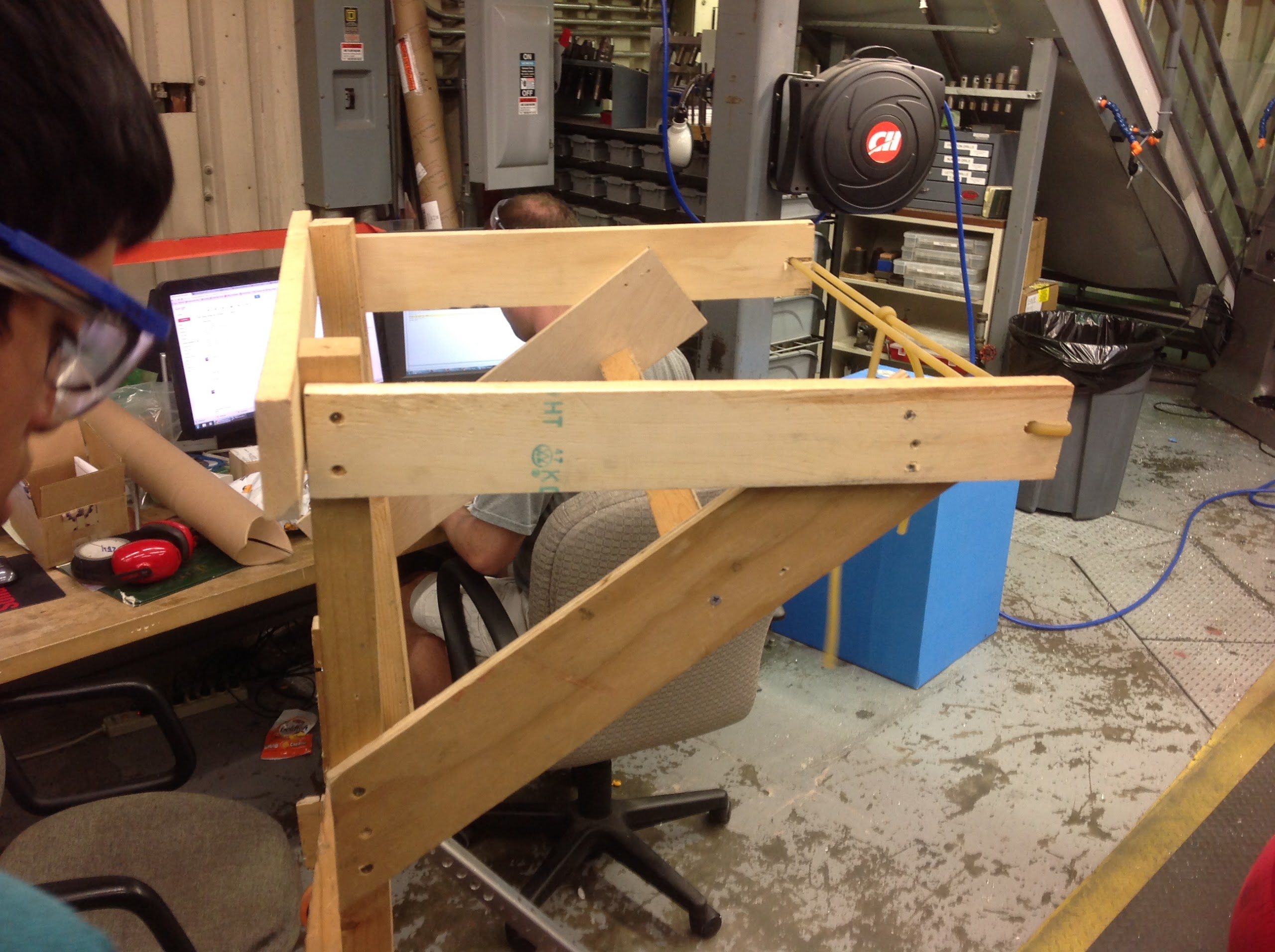

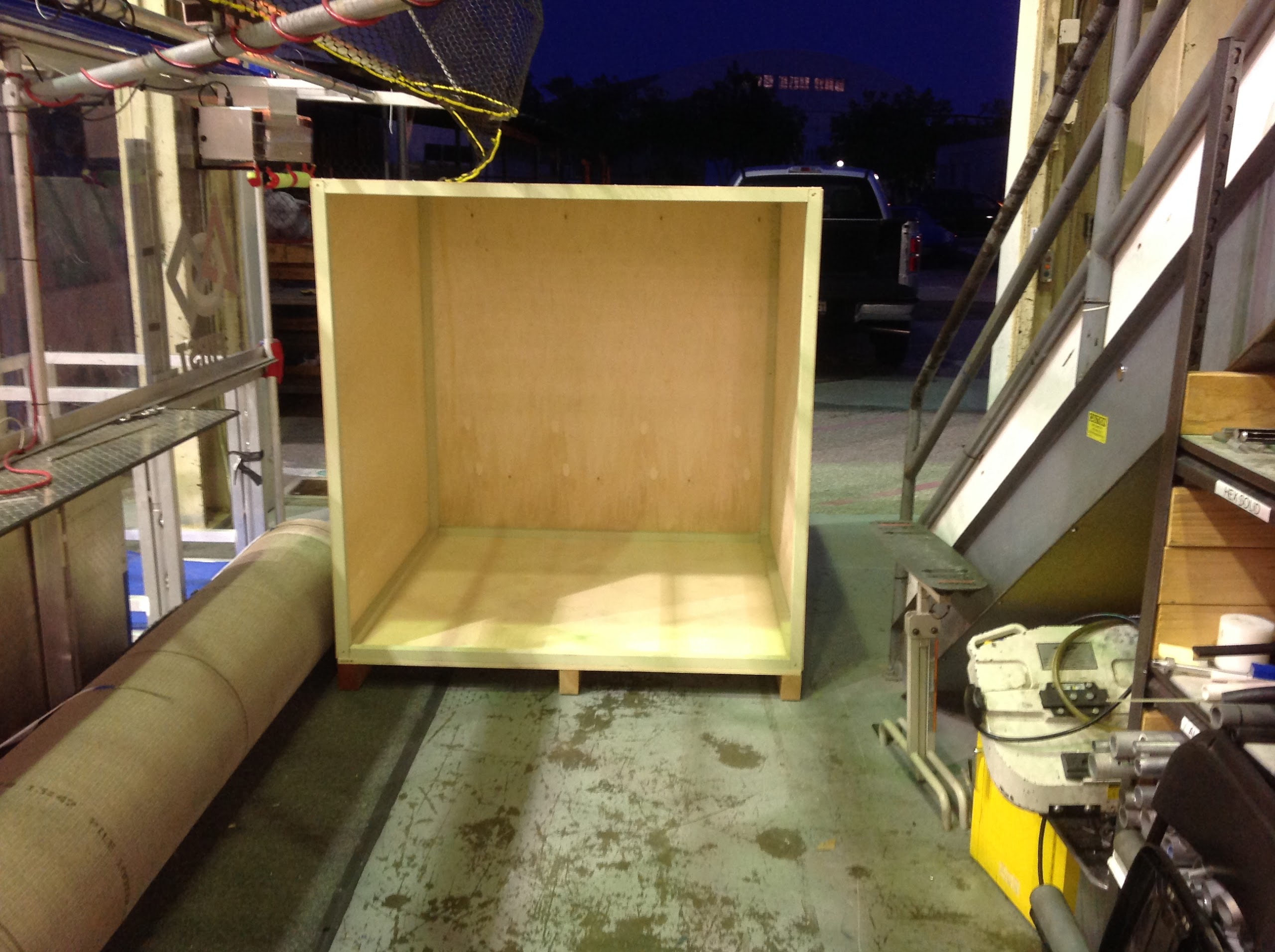

Prep for World’s

For the trip to St. Louis, all of the tools will be shipped in a 5’ x 5’ x 5’ wooden crate. Using the measurements from the CAD designed yesterday, the wood pieces were cut and assembled.

Action Items

- See board