Build Blog Days 16 and 17 (2/2/18 & 2/3/18)

Elevator

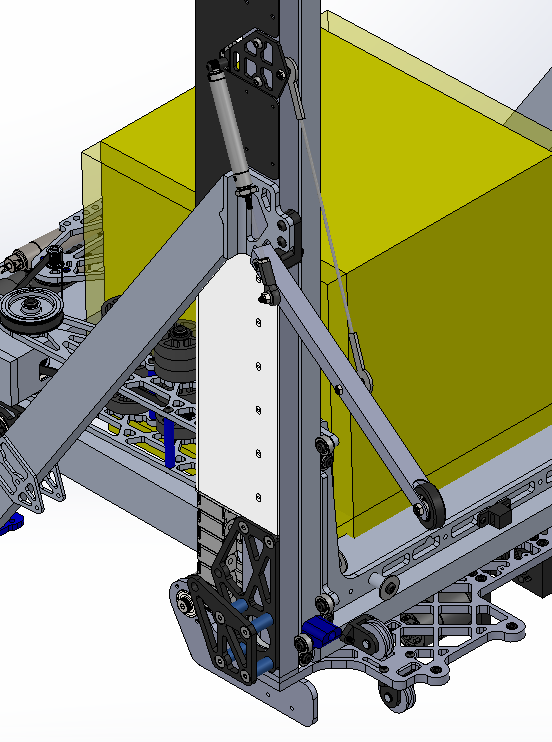

Task: Design Elevator Cartoon CAD

- We decided to offset the A-Frame from the frame rail to allow more space for the intake to open and close in between. To do so, this also required moving the frame rail closer to the elevator such that it would not interfere with the omni followers. We finalized the outer stage and A-Frame of the elevator, manufactured all the parts, and sent them out to be welded. We decided to have the igus chain ride on a polycarb guide on the same plane as the outer face of the upright. The igus chain will attach to the top of the polycarb guide, will curl around the side tube of the carriage weldment, and will bolt to the inside of the carriage. We also moved the pulleys in a little on the bottom side of the horseshoe to make space for our pit crew members to easily put in the thumbscrew bolting the bumpers to the back of the frame rail.

Forklift

Task: Design Forklift CAD

- We adjusted the forklift pivot and piston to work around the A-Frame by using a larger bore piston with a smaller stroke. We had initially planned on using a 3/4″ bore piston with a long lever arm, but because we decided to move it within a protected area and closer to the elevator, the lever arm decreased and thus required a larger bore piston to hold the forklift upright. We also finalized the tensile member which will be a steel wire bolting from the elevator to a-frame gusset to a standoff on the forklift and added a crossmember between the two forks.

Rollercoaster Wheels

Task: Complete Rollercoaster Wheels CAD Design

- We completed the design of the rollercoaster wheels. We decided to use metal lanyards as the deploying hardstop. In addition, we chose to use a ball bearing with a 3D printed cover to increase the size of the wheel without increasing the thickness.

Electrical

Task: Wire the Practice, Programming, and Competition Robots

- Over the past two builds, we completed wiring the practice, programming, and comp bots. We also installed all necessary gearboxes and chains on each drivebase. So far, the practice and programming robots are set with pneumatics. At our next build, we plan to finish plumbing the pneumatics on the comp bot.