Day 17: Design, Manufacturing, Prototyping & Programming Progress

Design

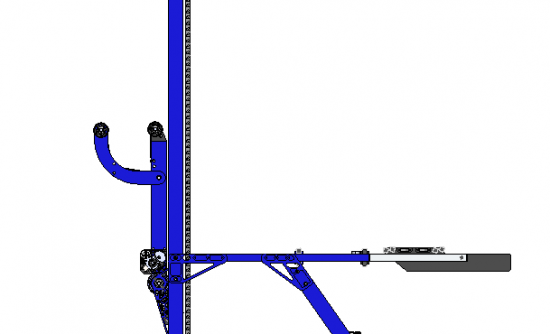

The design of the robot is coming along spectacularly. Since Saturday, we have continued the detail work on the various robot gearboxes and have continued on into Subsystem #4: Minibot Deployment. We have decided to build a secondary linear slider that will extend out the back of the robot, very similar to a horizontal version of our elevator.

We are building this instead of buying COTS linear sliders because off the shelf aluminum linear sliders cost upwards of $150 each and will struggle to get the kind of extension that is needed to get outside of the robot bumper zone.

Furthermore, we have begun the long and painstaking process of going through the models and picking out each and every fastener that is needed. We then must search the lab for the fasteners and if needed, add them to an order list.

Manufacturing

The manufacturing team was very busy today working on a myriad of parts. From tube standoffs to spacers and plugs, a number of parts came off the production lines on the bandsaw, shear, mill, lathe and CNC mill.

His name is El Sides and he likes to boogie. You may see him at the lab in his zip-up hoodie, turning parts on the lathe and he's like "Oh Goody!"

Prototyping

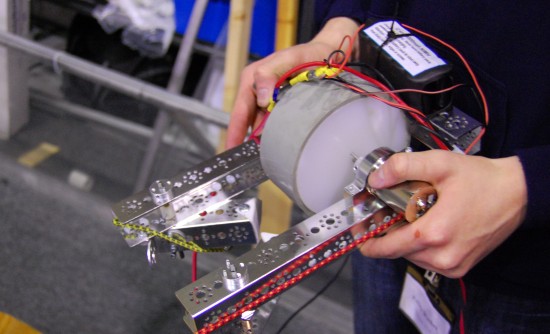

The minibot prototyping group was hard at work today changing up the design of the minibot. They are experimenting with different tread to see how it affects the climbing. Unfortunately, they blew a fuse on the minibot battery, so they are testing with an underpowered VEX battery for now.

Programming

The programming team has been hard at work! The robot team is working to implement PID control of the robot to ensure perfectly straight driving during autonomous. Furthermore, today they started looking at implementing control of the pneumatic systems of the robot.

Furthermore, the simulator team has successfully added a 3D view to the robot simulator and modeled the entire playing field and a mock-up of our robot with an elevator and an arm. The mock-up has the ability to hold on to tubes and score them on scoring pegs in all three dimensions of beautiful wireframe rendering.