Build Blog Days 18-27 (2/9/18 to 2/20/18)

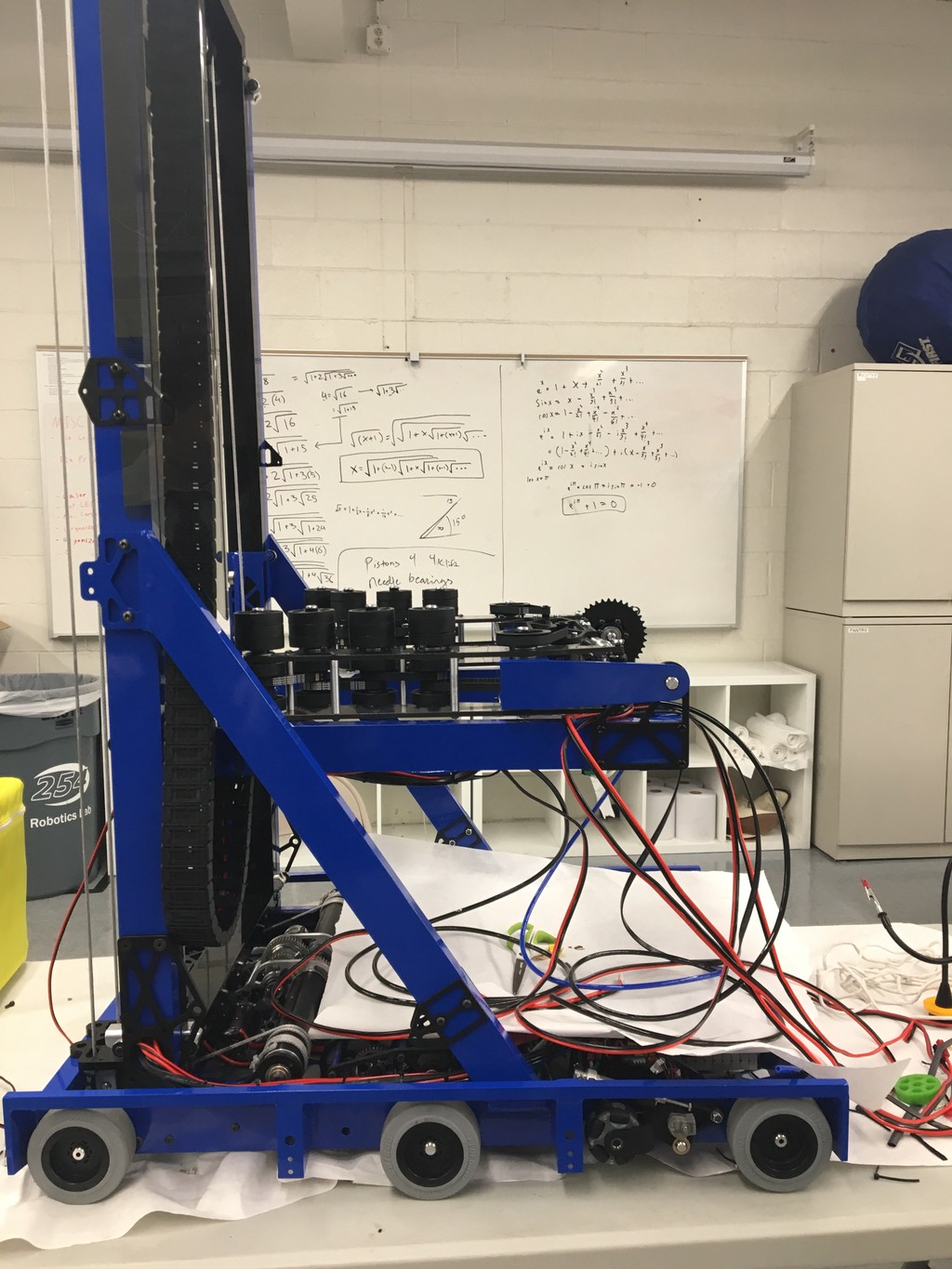

It's assembly time!

Part 1

-

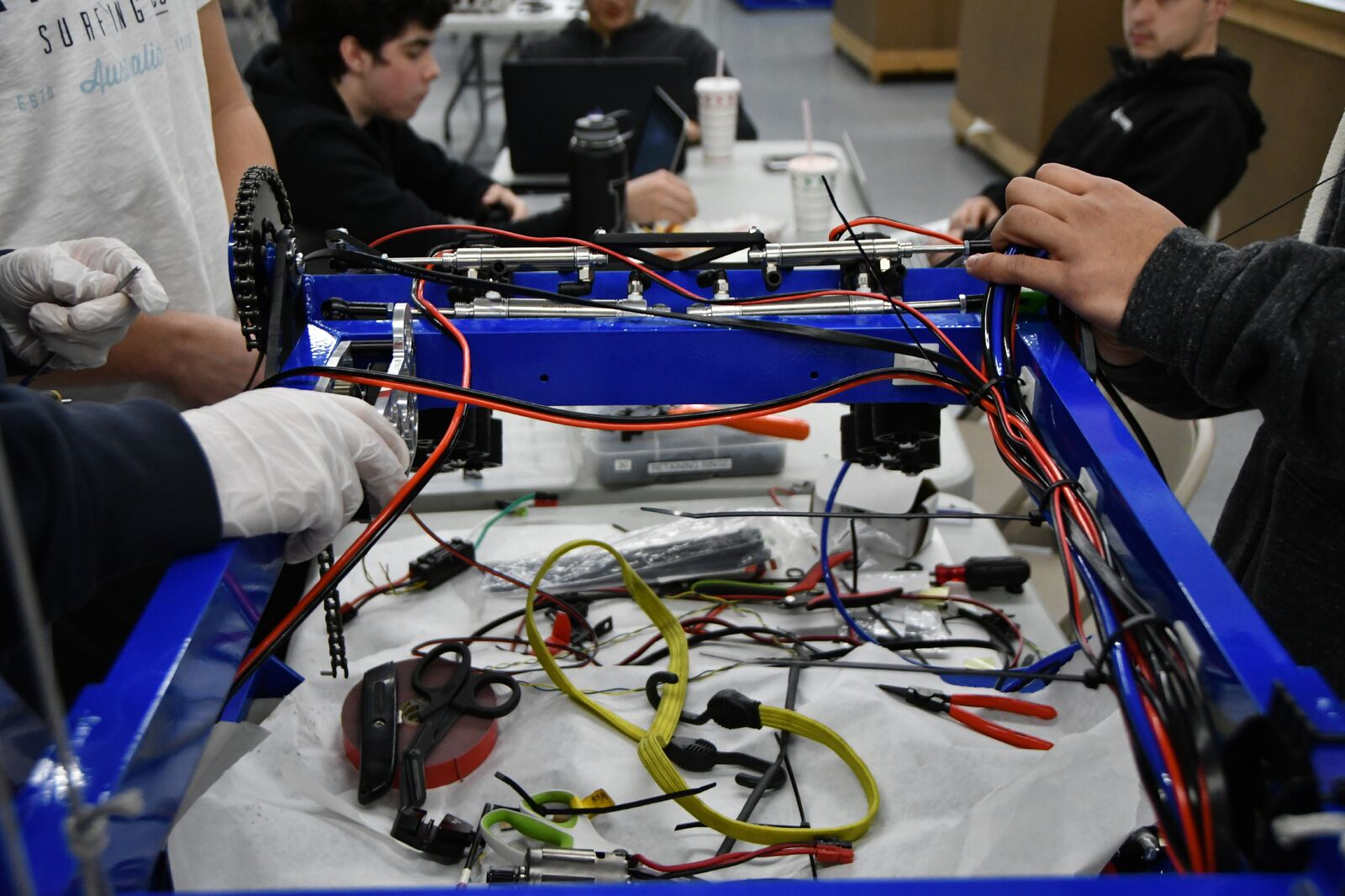

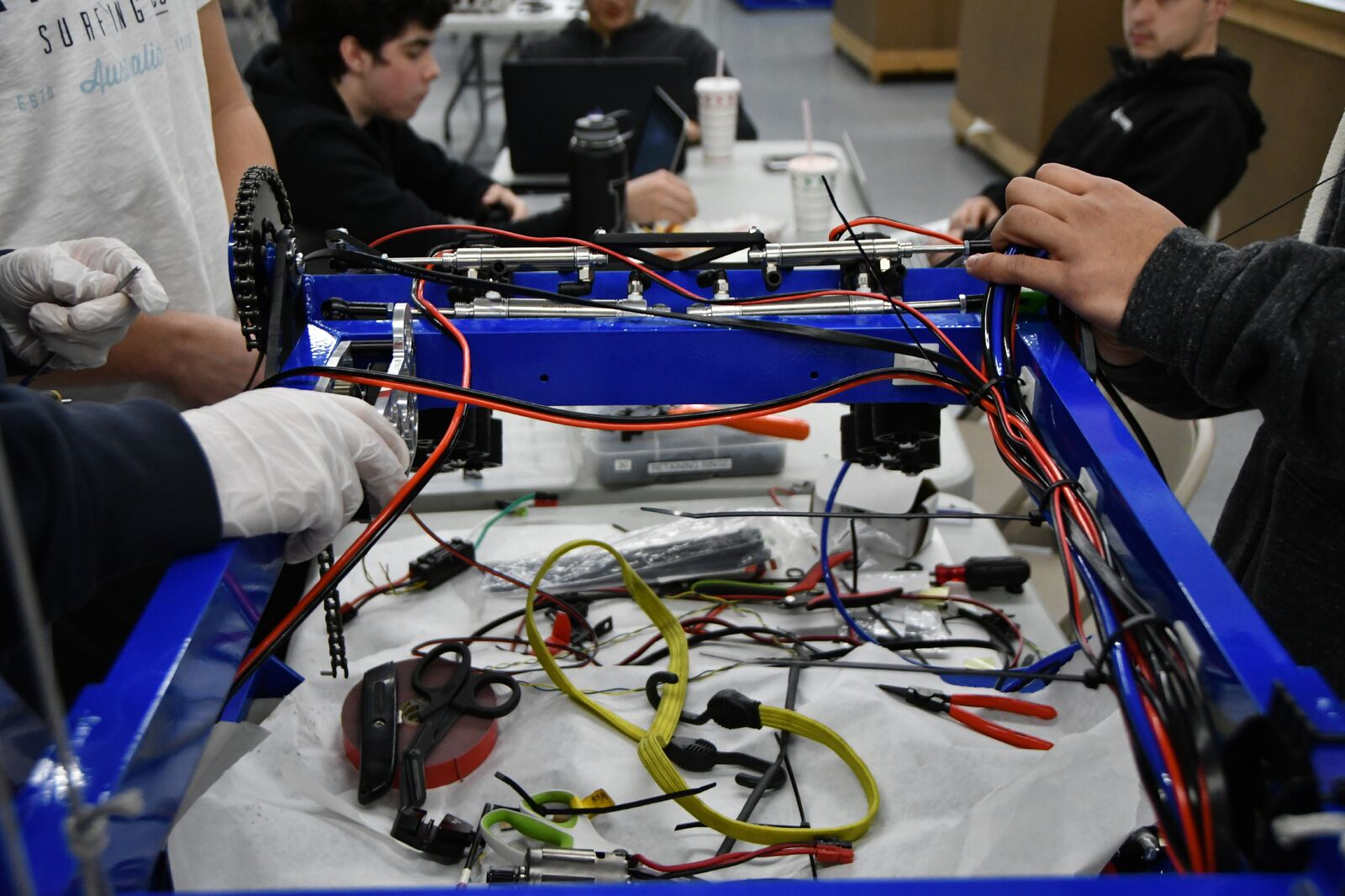

On Friday, 2/9, we assembled together the elevator on comp bot and tested out how wheel the intermediate stage and carriage slid with the bearing blocks. As we were sliding the stages, we noticed that the carriage was ripping off the powder-coating on the intermediate stage, so we decided to manufacture new inner stage uprights to be anodized for comp bot. We also assembled all 3 carriages and sanded down the welds. On Saturday, 2/10, we started putting everything together on all 3 robots. We installed all the bearing blocks and forklift brackets, and began wiring up the comp bot with the IGUS chain. We also decided to hook up a magnetic limit switch to the top of the horseshoe to detect the distance between it and the carriage. That switch will be connected to the encoder on the elevator gearbox. We also assembled an intake without the pivot arms and mounted it to programming bot to test out how well it works. On Sunday, 2/11, we worked on manufacturing more parts to send out for anodizing on Monday, 2/12, and we cabled up the elevator on practice bot and tested it out. We noticed that the elevator moves slower than we thought which may require a change in gearing, and we also noticed that the cable runs are too close together which may prove problematic for spitting the cube out the back.

- On Wednesday, 2/14, we began assembling the programming bot and competition elevator gearboxes. After testing the elevator on Sunday night, we realized that it moved much slower than expected. To fix this, we swapped out the last stage gear reduction from an 18:50 to a 24:44 which theoretically allows us to climb 78.5" within 0.76 sec. We got back the intake pivot weldments from powder-coating and assembled them on practice bot.

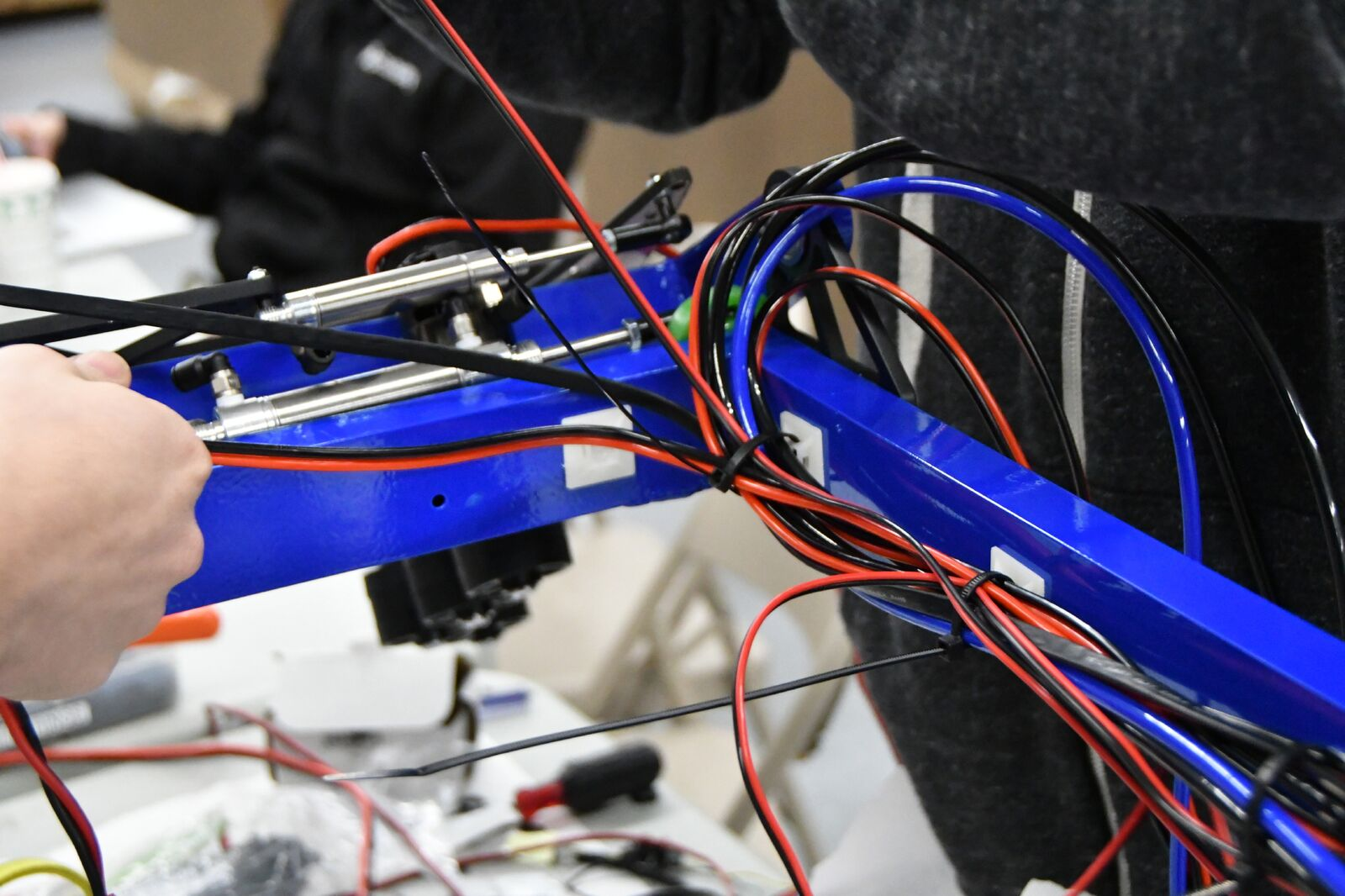

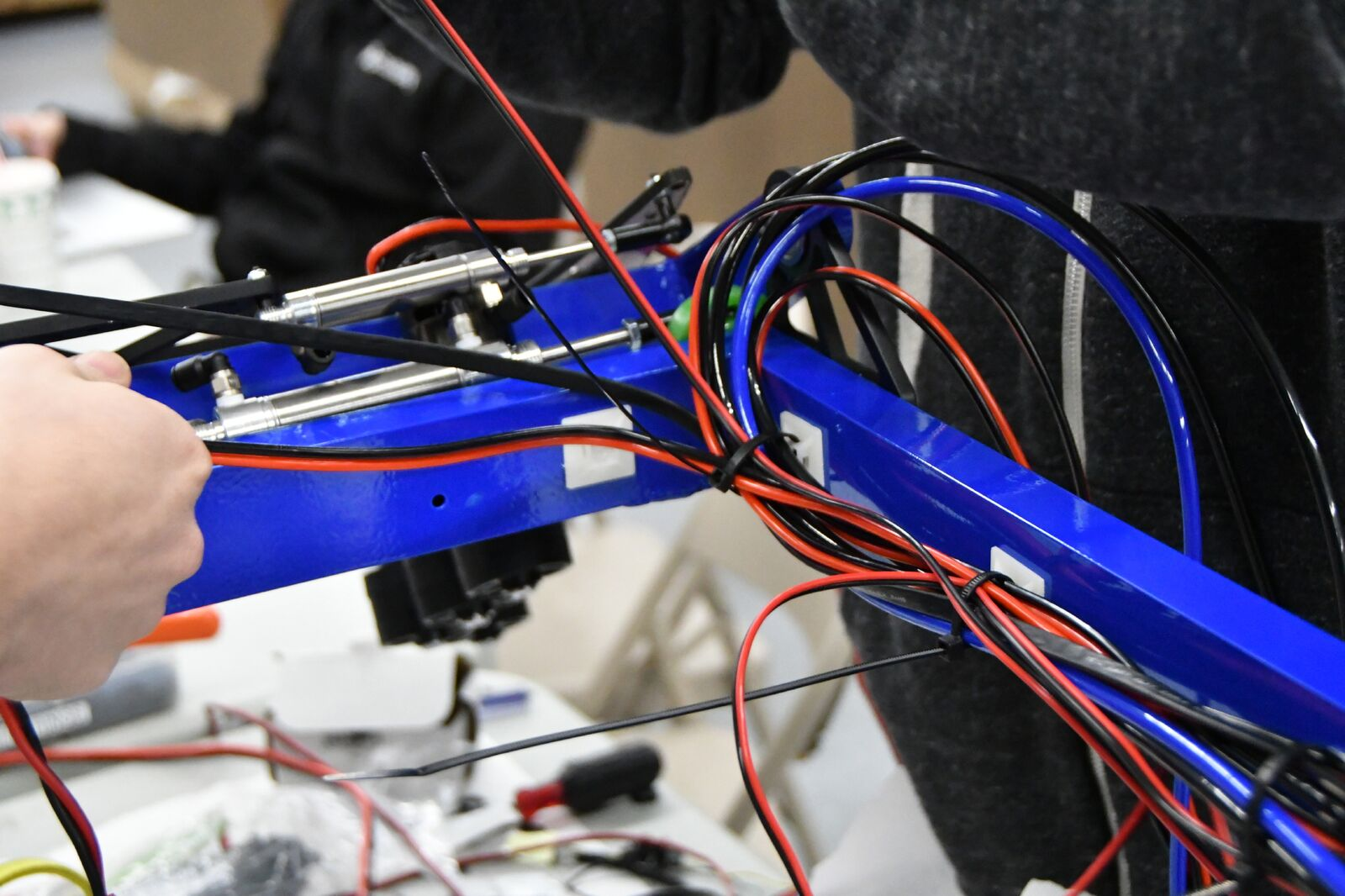

- On Thursday, 2/15, we continued work on assembling the intake. We wired up the CAN coming up from the PDP into the talon, then had the CAN daisy chain from the talon to the canifier, and then had the CAN terminate after the canifier with a 120 ohm resistor. The canifier will be used to breakout various DIO sensors we plan on placing on the intake such as magnetic limit switch sensors for soft stops for the intake pivot and beam break sensors for cube detection. We wired up the motors and pneumatics on the intake, and tested it out.

- After 4 intense days of early mornings and late nights, we bagged and tagged our completion robot last night! Thank you to all the students, mentors, and parents who made this build season possible!

- Saturday, 2/17: We handed off the the practice bot to the programmers to begin tuning the wrist pivot and the elevator.

- We wired up the carriage on competition bot by drilling in holes in the box tubing to channel the wires. We mounted the intake on the carriage and placed the magnetic limit switch sensor on the carriage pivot gearbox

- Sunday, 2/18: The programming team continued tuning practice bot. We continued assembling and wiring competition bot.

- Monday, 2/19: The programming team took competition bot to tune the mechanisms while the assembly team took practice bot to mount the forklift and hanger. We tested out both the forklift and hanger and saw that the sneaky hang with a partner was able to support two robots. While doing a solo sneaky hang, the robot did swing in which we expected to happen. We mounted a rollercoaster arm on practice bot hoping to counteract that swinging, but rather it only caused the robot to now pivot around where the rollercoaster arm contacted the scale. After all this testing, we decided to remove the partner hang and only mount the sneaky hang on competition bot.

- Tuesday, 2/20: Stop build day! We finished up all the wiring and assembly on competition bot and took pictures of it. In the last hour, the programmers took the robot to test it, and we noticed a few issues arising with the intake, Omni followers, and sensors which will need to be corrected at competition. We bagged the robot at 115.9 lbs as well as a tote full of spare parts.

Part 2

Our Final Robot