Day #15: Improved Shooter

Prototyping

Shooter

Students continued to make modifications to the shooter prototype. They removed the polycarbonate cover on the top of the shooter and replaced it with an aluminum bar to guide the frisbee through. In testing, the frisbees that are shot seem to consistently go through the high goal. The team expiremented with different shooter positions and angles in the testing, and measured the speed at which the frisbees were fired out. It was found that the frisbee’s velocity upon exiting the shooter was roughly 15 to 20 mph.

The updated shooter design

Intake

Not much work was done on the shooter today. With the current intake prototype, the frisbee seems to get stuck high on the intake ramp, not touching any vertical rollers. As of now, the intake has been taken apart so that the students can add metal supports (as opposed to wood).

Manufacturing

The team continued to manufacture parts for the drive chassis and prototypes.

Student making parts on the lathe

Programming

Sensor Testing

The programmers had a particularly productive day. First, they tested the S4 and S5 encoders. The team realized that the encoders or wiring appeared to be defective yesterday because the encoders kept returning 0. They finally realized that it was indeed a code problem, as they needed to call the start() function on the encoders to start recording clicks. After testing all the S4 and S5 encoders in the 254 electronics bin, all of the encoders were deemed as “functional”, with the exception of one S4 encoder. The broken encoder was promptly labeled as “bad” with the help of some blue duct tape.

Programming the sensors while wielding pool noodles

Reading Constants

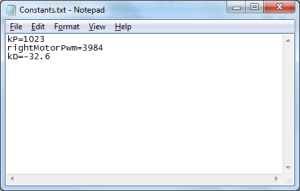

Meanwhile, the programmers tested out a method to read a text file from the robot (Constants.txt) and update the constants accordingly. At first, the team had problems with finding the text file on the robot. Previously, they had been using getResourceAsStream and InputStreams, but switching over to FileConnection and DataInputStream solved the null pointer exceptions. This was a major breakthrough for the programmers. Now, with a Smart Dashboard extension to send text files to the robot via FTP and a way to read and update constants from that text file, the programmers have achieved nirvana.

The Constants text file looks like this: a constant’s name = its updated value

CAD

Students began designing the intake mechanism in Solidworks. Though the intake prototype is not yet completed, this step is important because it helps to visually map out the prototype for future assembly.

Action Items

- Continue improving and testing shooter

- Reassemble and work on intake