Day 22: Programming, Prototyping, Manufacturing

Programming

Today, the programming team was hard at work on a number of projects. Their PID control of the robot is starting to work aweseome and the robot is at the point where it can traverse the whole field while only turning 1° (this translates to a ~1″ left-right difference from perfectly straight)

Furthermore, Daniel was able to implement motion control as a new method of controlling the robot. Using a PS3 controller, he has full control of the robot’s drivetrain, as demonstrated in the video below.

Prototyping

The prototyping group was hard at work today working on a completely new minibot prototype. After a review of the engineering design process, they worked on a new design that should deploy onto the pole even easier than any of the other prototypes. The design is slow and climbs the pole in about ten seconds, but is a step forward as far as deployment goes.

Manufacturing

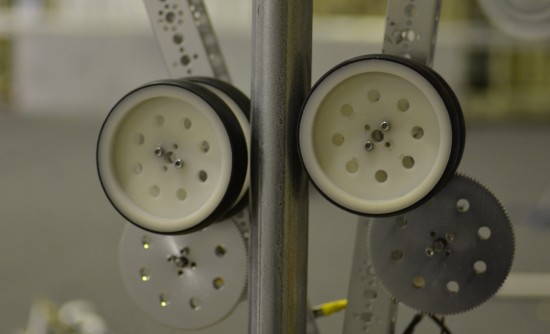

Today, the manufacturing team was working on a number of parts. They finished the carriage bearing blocks and grabber piston mount pieces. Furthermore, the group was able to machine the short plugs for the arm pivot tube and the arm pivot tubes. Finally, they turned the polycarbonate spool body for the elevator spool.