Day #32: Bumpers and Machining

Bumpers

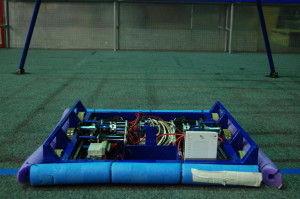

The wood and end-brackets for the bumpers were finished and assembled today. Afterwards some students worked on taping pool noodles to the sides of them (pool noodles are required by FRC as the official compressant in bumper assemblies). With the pool noodles on, the students worked on cutting cordura (fabric) to length and marking spots that the 254 logo would go.

Cutting the bumper fabric to length

Bumper skeleton

Manufacturing

The team worked on making shafts for the intake and conveyor. Meanwhile, Cory worked on CNC'ing the intake side plates. Students also used the mill to create wooden supports for field assembly. They are currently working on a way to mount the frisbee goals on the field walls.

Manufactured wooden supports

The wooden pieces attached

Programming

The programmers worked on fixing/tuning drive code to be more responsive both at lower and higher speeds. Later, the programmers also tested autonomous commands. The robot was able to drive for a certain distance and stop; the drive was controlled by a new PID controller. In addition, students implemented a second PID controller for turning.

Robot driving under the pyramid

The programmers also started tinkering with sending values over the internet to graph on a web browser. Some students worked on the web side, which dealt with getting the graph to display and plot points in a browser. They based their program off of last year's code. Meanwhile, other students were working on getting the robot to send the data via UDP. However, it was discovered that the JVM the cRIO is running doesn't support the 'datagram' protocol. The programmers will look into TCP to accomplish this goal.

Programming and researching the web grapher

Driver Practice

Towards the end of the day, the team's primary driver, Abhi Kumar, continued driver practice. He practiced navigating the robot around frisbees on the floor, as well as making 180-degree turns after driving forward.

The view from the control board

Action Items

-

Continue driver practice

-

Continue manufacturing for intake and conveyor

-

Continue bumper assembly

-

Fix/tune drive code

Lab closing time for the night was: 4:20 am