Day #33: Field Assembly and Programming

Field Assembly

Today, students set up the support structures at the two ends of the field to mount the high and medium goals. They finished milling holes into the wooden support blocks and attached them to the metal and PVC pipe frame. The "blue" side of the field's goal frame has been set up and aligned with the center of the blue pyramid on the field. The "red" side's goal frame is almost completely built, but requires alignment.

The red pyramid was positioned on the field today as well. The metal leg plates and the wooden floor plates have been set, but the carpet has not yet been cut and laid down over the pyramid base.

The goal support frames

The aligned red pyramid

Manufacturing

Students continued work on manufacturing the conveyor by cutting shafts to length.

Meanwhile, students stapled and stretched the cordura over the bumper skeleton to make the edges and corners thinner, as well as to place markings on it with tape. They measured and positioned the "254" logo on the bumper fabric by printing out a real-life size of the logo, which will help for embroidering the logo later. Afterwards, the red and blue bumper fabrics were brought to Mrs. DePalmo (a parent of a Team 254 alumnus) for embroidering the numbers onto the cordura.

Conveyor plates began being machined and are half complete.

Programming

Today, the programmers implemented a profiled PID controller for the drive train. Essentially, this lets the robot accelerate at a constant acceleration to a set "peak velocity", then drive at that velocity for a while, then decelerate at that same acceleration. When graphing velocity versus time, the graph looks like a trapezoid. This is useful for driving a set distance without too much overshooting.

In addition, the programmers wrote up a PID tuner that would send data from the robot via TCP (instead of UDP). As discovered before, UDP is not supported by the cRIO's JVM, so the students rewrote the code accordingly. When completed, the robot can send values such as current distance, target distance, etc. to a web browser, which can then graph the values. This would be useful later for PID tuning the drive, turn, shooter, and other subsystems. The sending method has not yet been tested.

Testing the profiled PID controller on the drive

Driver Practice

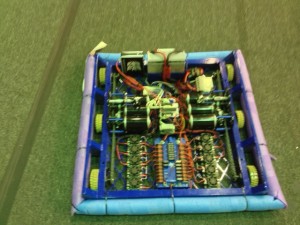

The team's driver got a bit of practice time today. Abhi Kumar, this year's primary driver, practiced navigating around the legs of the assembled pyramids. At first, the robot was in "low gear" and was making turns with a substantially large radius. However, with a flip of a switch on the turning joystick, the robot switched over to high gear, which was more sensitive and offered a much lower turn radius.

Action Items

-

Lay carpet over red pyramid base

-

Continue manufacturing of conveyor

Lab closing time for the night was: 4:30 AM