Day 3: Field Construction, Programming, Design & Manufacturing

Field Construction

The field construction team was hard at work today working on the two elements of the game field that we are building this week. We have constructed a shopping list and hope to buy the remaining materials tomorrow.

Programming

The programming team was working hard today on teleoperated and motor control code. They have designed an interface to separated the control system (joysticks, arrow keys, etc) from the code so that the robot can be easily modified to be driven by a variety of controllers. Furthermore, they performed experiments to measure how linear the Victor Speed Controllers are in their outputs. Using MatLab, they will be able to analyze this data and derive a function to linearize the Victor outputs.

Design

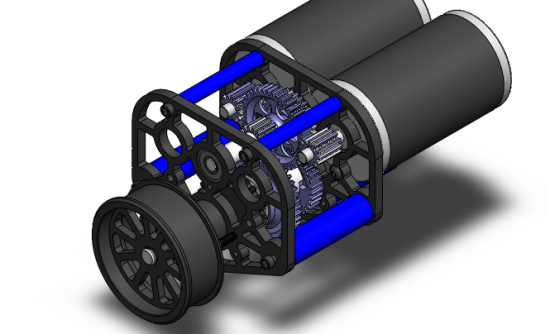

The design team was hard at work today. The first order of business was the drive gearbox. After the gear ratios were finalized last night, we were able to move forward with the drive gearbox CAD which his now completed. When doing the design, we were able to develop a new way of retaining the shifter shaft between the bearings to ensure that we can shift reliably. Without motors, the wheel and bearing housing, the gearbox is less than two pounds.

In addition to working on the gearbox, a group of students worked to design and CAD the drivebase frame. After careful review of the bumper rules, we decided on a design that would support the bumpers all along the back while still being extremely lightweight. We added a heavily pocketed baseplate and put the whole thing together for a design that weighs about 30 lbs.

Manufacturing

Production continued on the first operations of the bearing housings. We hope to finish the bearing housings by Wednesday.

Lab Improvements

Today, the wired network between the lab computers was completed so that they can all share printers.