Day 14: Prototyping, Manufacturing, Programming & Design Progress

Prototyping

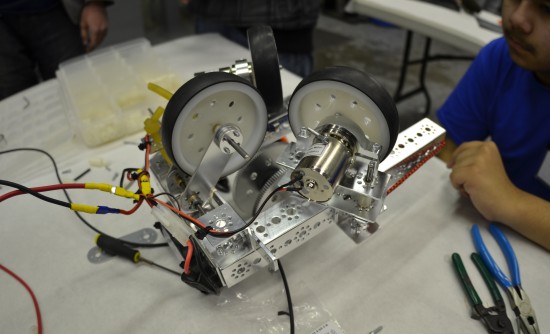

Today, the prototype group worked very heavily on the minibot design. Towards the beginning of the day, they successfully finished Minibot Prototype 1 and it climbed the pole.

After building the first prototype, the group started to discuss how improvements could be made to lighten the whole robot while making it climb faster. They decided that having a single concave wheel driven by both motors could potentially improve the design.

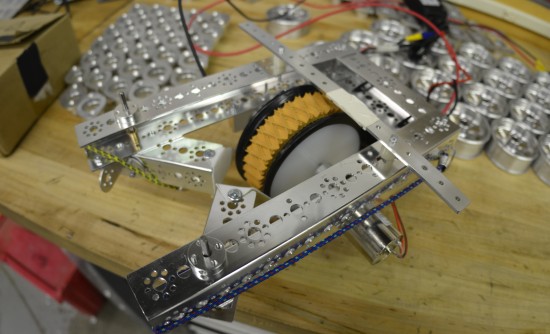

Minibot prototype 2 was built with one large wheel covered in tread and two stabilizers covered in slick teflon pads. It was not a significant speed increase over prototype 1 but it was much more stable.

In the next few days, we will work on ways to make it clip onto the pole more reliably and climb faster.

Manufacturing

Today, the manufacturing team was hard at work on several tasks. We began by finishing the front and rear bumper supports.

Furthermore, the team was hard at work starting on the tapped inserts for the elevator tubes.

Programming

Today, many programmers were hard at work both improving on the simulator and trying to refine their control of the robot. Recently, the simulator team worked to add a 3D view to the simulator so that the field can be better visualized. The robot team was working on using PID control to allow the robot to drive precise distances.

Most of the members of the programming team were present today, working hard on the simulator and the robot.

Design

Today, several members of the design team worked on the arm pivot gearbox. The gearbox is mostly complete.