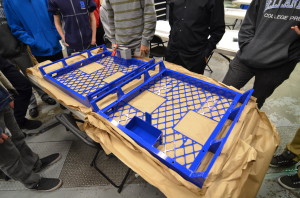

Day #18: Powder-Coated Parts

Prototyping

Intake & 2010 Robot

Students continued to develop an intake prototype, now attached to Onslaught, and the intake will be completed as soon as possible. However, due to the arrival of the chassis, students removed Talons from Onslaught to be placed on the new drive chassis. This transfer means that we do not know which robot (Onslaught or Skyfire) that the drivers will practice on, but Onslaught will still be used for testing sensors.

Manufacturing

Today, GIlbert Spray Coat returned the powdercoated chassis a day earlier than expected, and students began working on putting electronics onto the frame, such as the power distribution board, ten Talons each, digital sidecar, the Spike relay, the power switch, and solenoid. Additionally, Pacific Coast Metals returned other anodized parts, such as gearbox plates and spacers.

If the shafts are returned from Modern Machine Company tommorrow, work on assembling the gearboxes will begin. However, there are a few missing parts that still need to be aquired. The 40T gears, shifting dogs, shifter shafts, and a few other parts from West Coast Products are still missing.

The bearing housings were received from Pacific Coast. Mentors and students worked on pushing the bearings into these housings

The two powdercoated chassis

Programming

Today, the students spent most of the time trying to make a VEX ultrasonic sensor work on an FRC robot, in order to determine the orientation of a Frisbee. Most of the time was spent debugging the sensor, as the sensor was returning arbitrary and random values. The programmers discovered that the two port numbers should be switched in the code, which made the ultrasonic sensor work. However, during testing, the sensor seemed to be able to detect surfaces a maximum distance of around 3 inches away. This is a problem, as the VEX ultrasonic sensors are designed to be able to detect distances of up to 115 inches away. The team thinks that interference from the surroundings could possibly affect the sensor’s abilities, but more tests and debugging will be done tomorrow to get to the root of the problem.

In addition, a couple of the robotics laptops were transfered to the lab for programming use; however, the nature of the Bellarmine servers prevented work from being done on the laptop. Currently, the team needs to reinstall the wireless card driver on the laptop.

Action Items

- Debug and test ultrasonic sensor

- Continue working on the intake

- Continue adding electronics to the chassis

- Continue designing the shooter, climbing mechanism, and intake

- Start wiring