Day #28: Auto Scripting and Bumpers

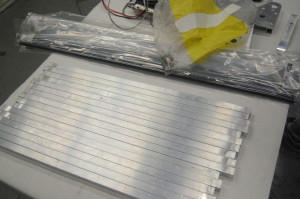

Bumper fabric

A few members measured fabric for the bumpers and measured where to properly place the team logo on them. They were careful with measurements because the ideal bumpers are more compressed than actual ones that will be.

Measuring the cordura

Wiring

Members starting wiring the cRIO on the competition robot. They also started wiring the encoders on the practice robot.

CAD

Members and mentors looked through all parts in the CAD and placed the rest of the part orders.

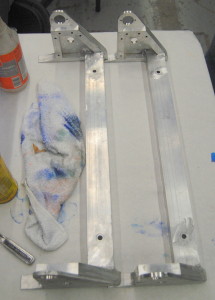

Parts

The team received the welded intake mounts and crossbars from sponsor Central Concrete. The welding left some rough edges, so some members and mentors used the pneumatic grinder to smoothen sections on the intake mounts. Overall, the welds turned out great and the assembies seem to be extremely strong. The team was a little disappointed in the welding on the intake mounts. It was very “globby” and had a lot of excess metal that didn’t seem necessary. After a bit of cleanup, it looked better. Hopefully the intake mounts will maintain their structural integrity throughout the competitions.

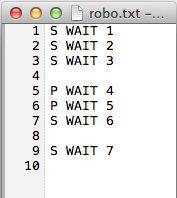

Programming

The programmers worked more on the autonomous scripting. They added a feature to the auto command file reader that allows the user to denote whether commands should be executed sequentially or in parallel.

They also began work on a testing system that cycles through and briefly runs each of the six drive CIMs of the robot. The purpose of this is to test these motors of the robot and isolate problems before competing, allowing the team to diagnose and act on the problem. For example, the pit crew could activate this to verify that the drive motors function properly before matches.

Action items

- Finish wiring the competition robot

- Finish wiring encoders on the practice robot

- Cut bumper fabric

- Document auto script file format

- Finish code to cycle through subsystems