Day #29: Bumper Construction

Bumper

Over twenty students and two mentors collaborated on measuring and cutting the wood for the bumper. Students measured the bumpers to be 5" in height and lengths of 28.25", 28", and 8" for all of the sides of the perimeter. They then went outside to cut it with a miter saw. Students later brought the pieces to the mill to fine-tune the lengths to be precise. They will be assembled together next.

Milling wood frame to length

8" wood

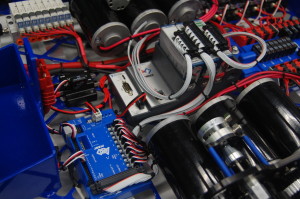

Wiring

EJ and Jonathan Lee led other students to continue wiring on the drivebase. They then stripped, crimped, and soldered the encoder wires to the digital sidecar through PWM cables.

Encoders

Programming

Today, the programmers conducted more tests with the autonomous scripting command parsing. The team had a discussion at the whiteboard and talked about the sequence of excecutions of a mix of parallel and sequential commands in a CommandGroup. One topic that came up was the ability to treat a group of commands as one group that runs parallel to each other, and will not move on to the next command until all the grouped parallel commands were completed. However, it was decided that this logic should be used in the writing of the autonomous script, using a clever mix of parallel, sequential, and wait commands.

Meanwhile, students also implemented the Indexer class, which represents the system that grabs a frisbee from the intake and prepares it to load into the shooter. The indexer has two Solenoids as instance variables, and has getter and setter methods for the states of the two pistons.

Action Items:

-

Finish wiring the competition robot

-

Release more parts for manufacture

-

Mill pockets in bumper wood

-

Wire Pneumatics

Lab Closing Time: 12:30