Blog - January 2010

CAD and Prototyping Progress

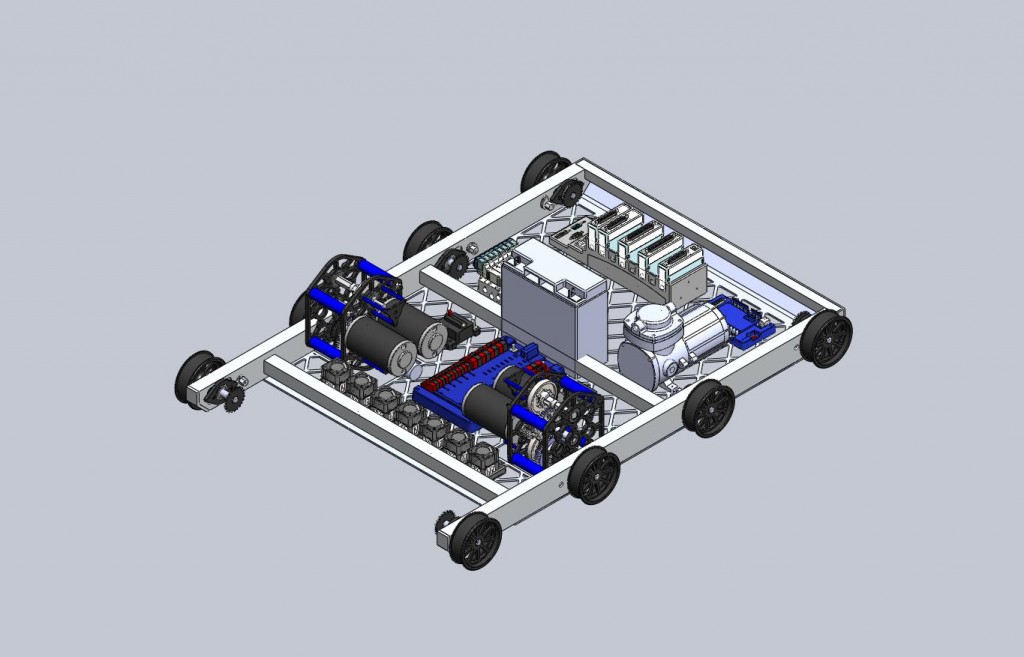

Today, Team 254 prototyped a mechanism that keeps the ball in place while kicking and helps the release of the ball. We also mounted the kicking prototype onto our drive base prototype, and began to mount the holding mechanism. We completed the CAD of our basic drive base, and came up with possible placements of the electronics board, as seen in our earlier post.

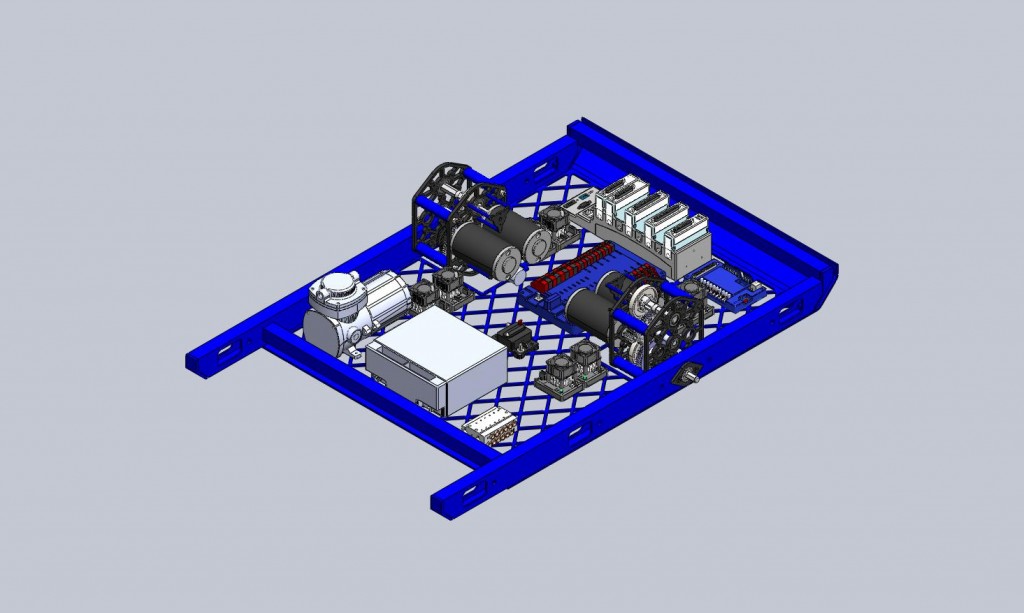

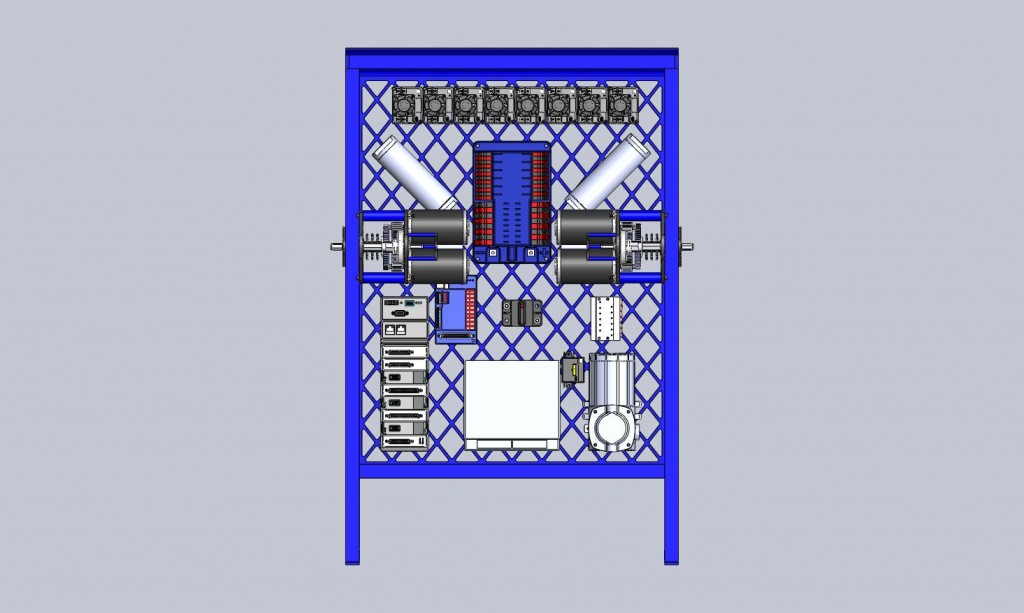

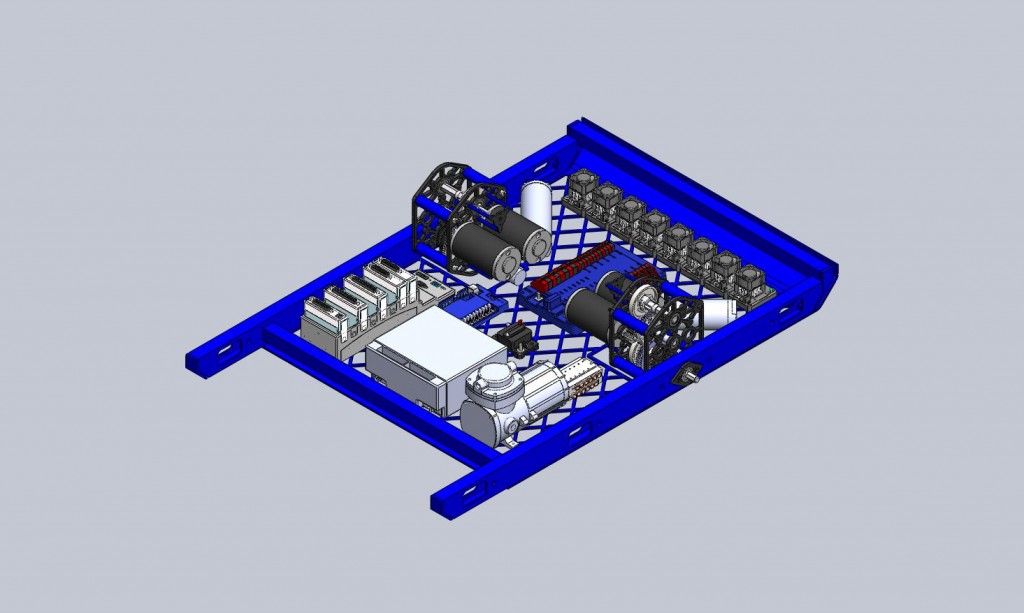

CAD Progress

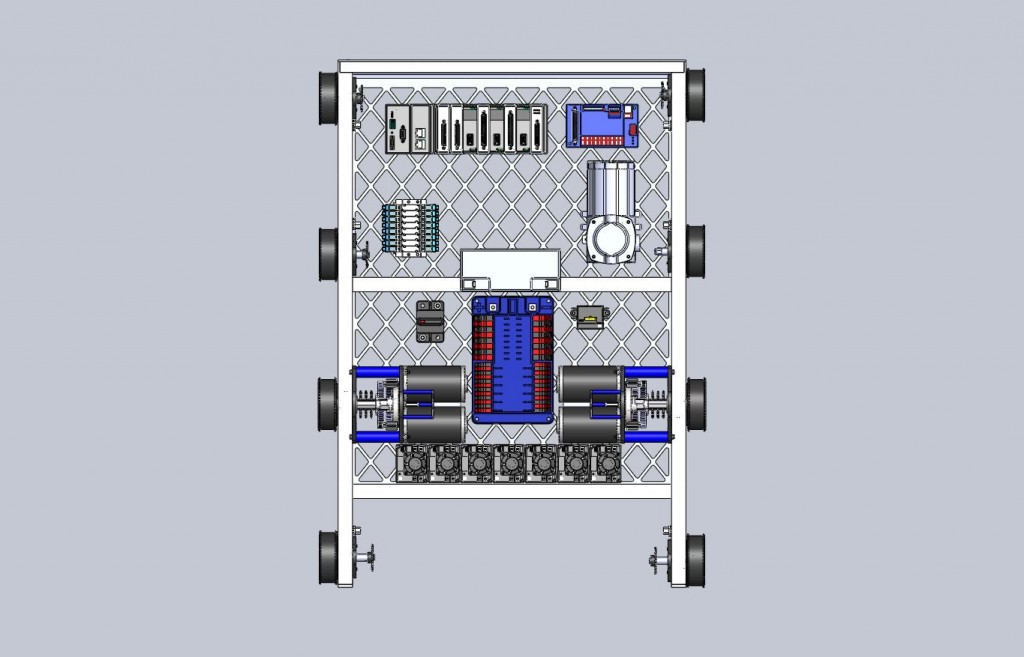

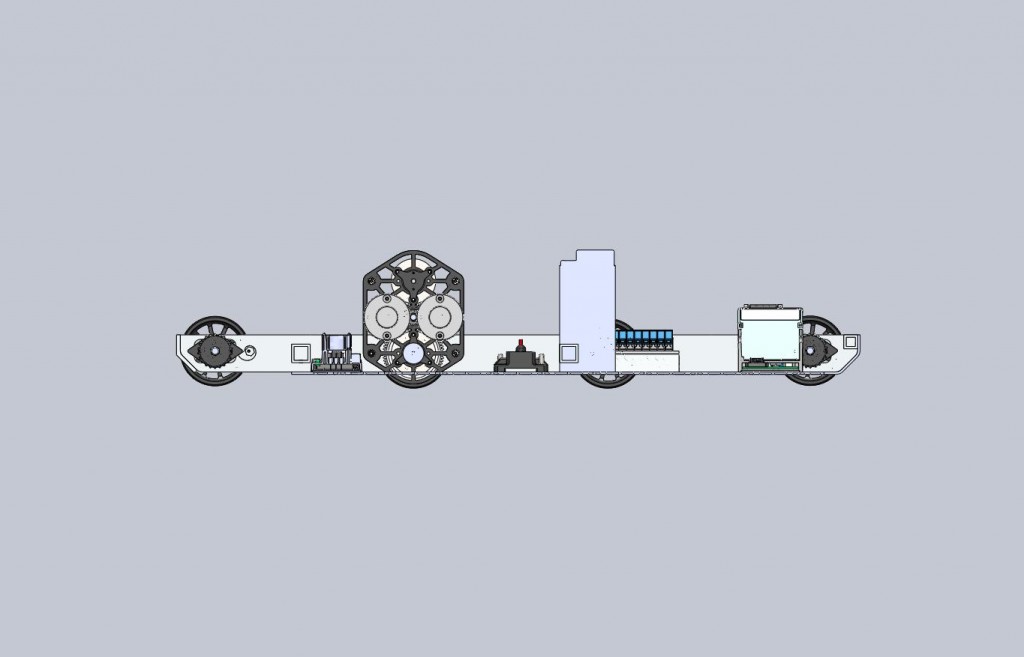

Today, the CAD team continued to work on the drivebase frame. The back bar for hanging was scrapped, out of concern that there would not be ample room between the bar and the bumpers for an alliance partner to get a hook in. We extended the base plate to the very back of the frame and started to lay out electronics. We are starting to think about what our ball handling mechanism will look like, and how to design the electronics to stay within the constraints that the ball handler gives us.

Organization & Machining

At the lab yesterday, the team continued working on improvements to their prototype . The machining of the wheels has started, meaning we will soon be working on the tread for the wheels. Finally, the team began organizing the bins filled with old motors and parts, as well as locating bearing blocks for the robot.

Drivebase Design & Manufacturing Progress

At the Cheesy Poof lab today, several objectives were accomplished. The gearbox design was finalized. The drivebase design moved forward, and the basic frame is set for it. It features a large tube on the back for alliance partners to hang their robots from for bonus points. The electronics board will mount between two square tubes.

The manufacturing team continued on the manufacturing of the Bearing Blocks. They are about 1/2 done with the 2nd operations on all 140 bearing blocks, and will finish tomorrow. A group of students cut metal stock for the wheels, on which machining will begin tomorrow.

Vacuum Suction Testing

Since the ball may only roll 3 inches into the robot, we wished to study the plausibility of a vacuum holding system. In the 2008 Overdrive game, Team 1771 successfully used a mini shop-vac impeller driven by two Fisher Price motors, to posses and lift the 8lb track ball. For our test today, a Shop-Vac brand “Hang-Up Mini” model was used. This is a 120VAC 6.2A model. As shown in the picture below, the impeller is approximately 4 inches diameter, one half inch thick, and very light weight.

After reassembling the vacuum, a plastic funnel of approximately 4 inches diameter was affixed to the hose. A small basketball and a rubber exercise ball were used for the test (no soccer balls available at testing location). No seal was used around the lip of the funnel. The vacuum held the small basketball very well, and the large exercise ball moderately well. While seams in the balls did not greatly affect the holding power, we speculate a larger funnel with a lip seal/gasket would improve the results greatly.

A video of the test is shown below:

(There was a video here that has sadly been lost in the archives.)

We have not yet determined exactly how a mechanism like this might integrate with a kicker.

We also observed the suction power directly from the impeller housing:

(There was a video here that has sadly been lost in the archives.)

The testing revealed the vacuum produced greater suction and holding power than expected, and could potentially be a successful soccer-ball holding device. Further tests would have to be done to power the impeller with KOP motors (such as two Fisher Price motors, as 1771 did in 2008).

Ball Launcher Prototyping

Earlier today, RAWC students and mentors brainstormed ideas while at the high school, coming up with a few mechanisms to launch a soccer ball. A few of those ideas were actually plausable(we went forward with one). We built a launcher frame that takes into account the size restrictions placed on teams(Ball can only be 3″ inside the ‘bot, Launcher mechanism can only protrude 2″, Ball must stay in contact with the floor).

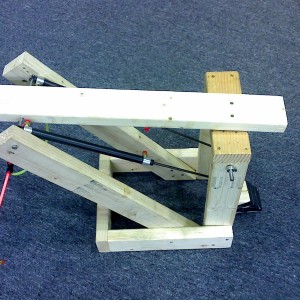

Here’s a photo of the launcher.

Here’s the release mechanism:

Here are a few videos:

Long Range (Corner to Corner) Preset Test. This test was setup having the launcher’s frame(the size of the 2009 base) touching the wall of an alliance station. The frame was also pointed toward the opposite corner(diagonally). After launching the soccer ball using the long range setting, the ball landed approximately 2 feet away from the opposing alliance’s home zone.

(There was a video here that has sadly been lost in the archives.)

Mid Range (Corner to Corner) Preset. This test was setup having the launcher’s frame(the size of the 2009 base) touching the wall of an alliance station. The frame was also pointed toward the opposite corner(diagonally). After launching the soccer ball using the mid-range setting, the ball landed close to the midfield divider.

(There was a video here that has sadly been lost in the archives.)

Ramp Contact Testing. This test was configured in a way that a KOP tote was placed in varying distances from the front of the soccer ball. We tested the following scenarios: Tote 4FT from ball(long range), Tote 4FT from ball(mid range), Tote 2FT from ball(long range). During our testing, we determined that the ball does not come close to touching the tote in all of the configurations. We performed one additional test that was not documented; the tote was placed 2FT from the ball and the launcher was set into the mid range position. The ball clearly comes in contact with the tote, altering the trajectory of the object.

(There was a video here that has sadly been lost in the archives.)

Additional ramp contact testing. These videos include a plane that is angled to a 45 degree slope. In addition, the ball is in contact with the inclined plane. This test was to demonstrate the launcher’s capability to launch a soccer ball accurately in the case that it was touching the ramp.

(There was a video here that has sadly been lost in the archives.)

Angled ramp contact testing. This test is to demonstrate the effects of using our launcher while being offset from the ramp.

(There was a video here that has sadly been lost in the archives.)

Build Day 5

Today at the Nasa lab we had roughly 12 students experimenting with various prototypes for kicking/launching mechanisms. One group seemed to find particular success with a pneumatic-kicker, which was able to launch the ball just over the hump attaining a distance of about 15 ft.

The girl scouts also came up with an interesting concept of a surgical-tubing powered scoop. This design may be promising, but has not been sufficiently tested yet.

Meanwhile the design team worked diligently upstairs properly tolerancing the gearbox and shafts as well as designing the 4″ wheels (see previous post).

In the machine shop the CNC began rolling out the bearing blocks, doing the second pass. By the end of tomorrow the bearing blocks should be ready for anodizing (provided there are no unseen complications).

Tomorrow the material for the wheels needs to be cut out so they are ready for machining. Pushing or launching the ball past the ramp has proved difficult, requiring excessive propulsion or front-spin and we will continue prototyping different designs.

Wheel Design

The wheel design has been completed. The wheels weigh 0.30lbs each and construction will begin tomorrow.

Manufacturing Progress

Today we finished the first operation on all 140 bearing housings. We began machining the backsides of them and expect to be finished tomorrow evening or early Friday, at which point we will begin machining wheels.

Build Day 4

At Team 254’s lab today, we had an extremely large number of people working hard to complete some common objectives.

In the manufacturing department, several students continued cutting stock for the bearing blocks. Many of the bearing blocks have already completed their primary operation on the CNC mill.

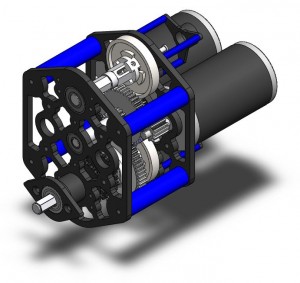

In the design department, a very large group of students worked downstairs all afternoon to continue to develop prototypes for ball launching devices. Some have been modified and improved to be tremendously more powerful than their previous states. Upstairs in the CAD department, a small group worked hard all afternoon to CAD the Drive Gearbox. As of 10:00 PM, the gearbox shafts are mostly done, but still need to be toleranced, which will be completed tonight to finalize the shaft drawings. In the morning, the drawings will be sent to 968 and Pacific Precision for the shafts to be completed this week.

This week, the design team will finalize the gearbox and design the drive wheels so that the gearbox plates can be manufactured by Team 233 in Florida. The manufacturing department will continue to manufacture the bearing blocks and will move on to the wheels once the bearing blocks are completed.

Winch Gearing & Performance Calculations

See the linked PDF below, for some important calculations regarding gearing and performance of the winch. The run-through of the basic calculations should be understandable by the astute high-school student.

Please let Dave know if there are any errors in the calculations, and it will be corrected accordingly.

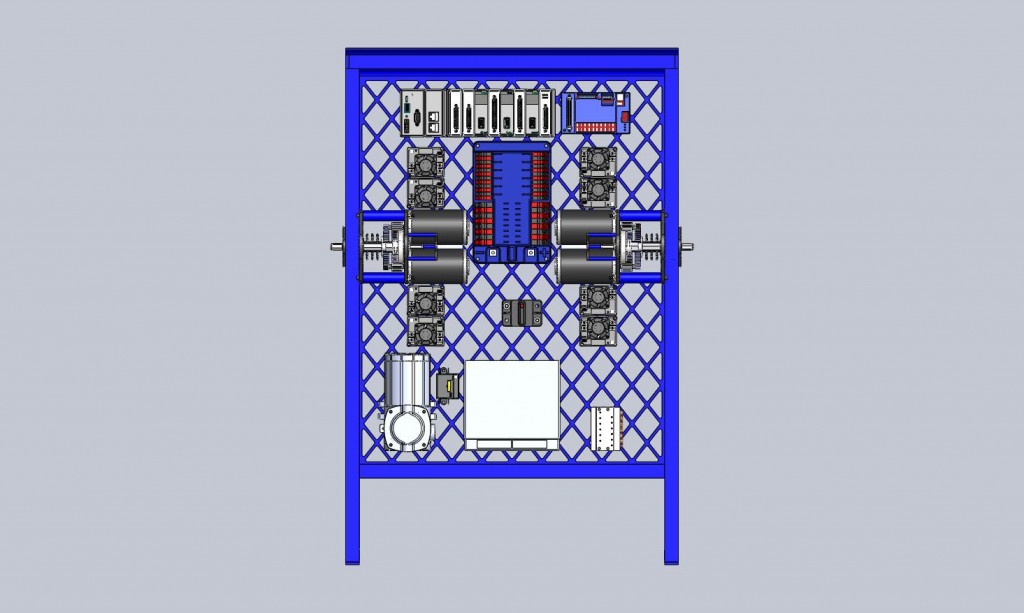

Final Ratios & Gearbox Info

Agreed Upon Specs:

2 Speed with Power-Take-Off (PTO) for Winch

4 CIM motors, 2 per side

Initial Reduction – 12:45

High Speed Reduction – 30:48 gives ~15.5 fps at 93% efficiency

Low Speed Reduction – 14:64 gives ~ 5.5 fps at 93% efficiency

All gears are AndyMark except for the 64 tooth dogged gear, 45 tooth intermediate gear, and the 30 tooth internediate gear, all of which are standard Martin gears.

The PTO shaft sits above the intermediate shaft and has one speed, and an the option for two with the addition of another three position piston. We also have the option of disengaging the output to the wheels if we use another three position piston.

Options Clarified:

1. Wheels move when winch is engaged – two standard pistons required per gearbox

2. Wheels do not spin when winch is engaged – one standard piston, one three position piston

3. Wheels spin when winch is engaged, but winch now has 2 speeds – one standard piston, one three position piston

4. Wheels do not spin when winch is engaged, and winch has 2 speeds – two three position pistons

The cost of the three position pistons is ~$70. The cost for the standard piston is ~$20. The gearbox will be designed to accommodate any of these options without the need to change ratios, plates, shafts, etc.

Ball Launcher

(There was a video here that has sadly been lost in the archives.)

Angled Tests

(There was a video here that has sadly been lost in the archives.)

8 Wheel Drive Tests

(There was a video here that has sadly been lost in the archives.)

Wheel over bump storyboard

Check out the different positions as these configurations go over the bump.

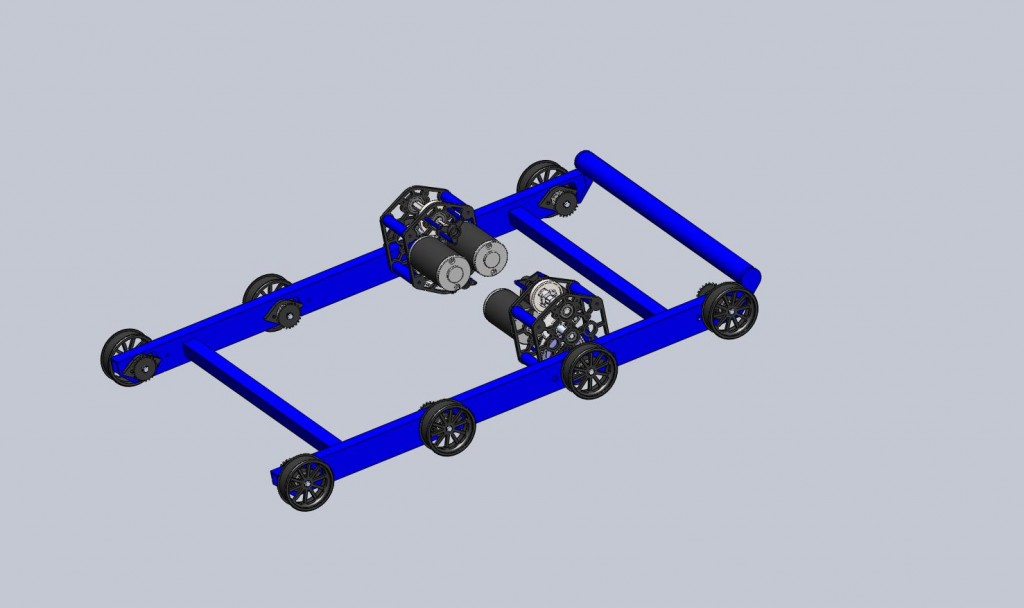

Build Day 1 Meeting Minutes

- Ideal design would utilize a rigid 6 wheel / 8 wheel structure

- Ideal design would also incorporate a mechanism that will allow the robot to traverse over bumps quickly

- Both teams are wondering on the usage of 8″ inch wheels. (Additional gearing)

- Recommended Protyping: Build 6″ wheel chassis on 6 wh/8 wh base

- Didn’t discuss ball manipulation mechanism

- Winching should be relatively easy

- The transmission should be the most important part of this game

- 254 disagrees to lifting up two other robots(Reasoning: 50 lbs of parts for 6 points)

- 254 recommends that we should winch ourselves

- 254 will test 8″ and 6″ diameter wheels on 06 bot.

- 968 will do CAD on wheel base distance with various wheels and distance from center to center.

Build Day 1

After returning from our Kickoff meeting at Bellarmine, Team 254 returned to the lab to start field construction. We sorted through the carpet to find the biggest and least worn continuous pieces and lay them out. They were then seamed together with carpet tape.

We also constructed one of the field “bumps” from the official FIRST drawings using 3/4″ plywood. We then proceeded to place different configurations of wheels on robots and roll them, unpowered, over the bump.

We’re currently looking into building a powered drive train for 8 wheels with rigid frame rails for additional testing.