Blog - February 2010

Software and Hardware Testing/Progress

Today in the Systems Engineering and Integration(SEaI) division, students and mentors tested the gyroscope assembly (PN: 1010167) and integrated the part into our system. SEaI also began developing software routines for a closed loop control of the robot when there is no steering input. Tomorrow, SEaI will also begin development on the autonomous routines/controller for the robot. SEaI hopes to replicate the 2008 968 autonomous controller with major changes, which, makes the system more efficient and elegant.

At DAVECO, David and his associates assembled the bumper assembly minus the Cordura fabric. Mock-ups were developed to visualize the stitch patterns required to have bumper fabric with no folds. The contractor will continue manufacturing of the bumpers for the next few days.

Stay tuned.

Progress

Today, the team worked to optimize the kicker and arm. The surgical tubing on the kicker was replaced with trampoline springs, to make it more easy to get a repeatable and known force. A gas spring was installed on the first stage of the arm to aid in arm deployment. Finally, limit switches were added in the pole grabber and on the arm to completely automate the lifting.

Now, thanks to help from the software team, once the arm deployed switch is flipped, the arm will deploy automatically. While the switch is still up, the robot will lift immediately once it is locked onto the bar and will stop when it has reached its final lifted position. This automation is an improvement in speed over what human drivers were able to obtain, due to prior uncertainty about whether or not the robot was locked on the pole.

Design Progress

Today, the design team worked to design the polycarbonate side shields for the robots. Due to weight issues, we will probably not be able to implement all of the polycarbonate shields on the robot.

The team also designed the cutouts which will be made on the bumper spacer tubes. The cutouts reduce the weight of the tube by over 50% by pocketing the side faces to keep proper bumper spacing and facing down the top and bottom faces from 1/8″ to 1/16″.

Score to Hang – 10 seconds

With mentors as drivers, no less…

(There was a video here that has sadly been lost in the archives.)

Design & Manufacturing Progress

Today, the design team completed the design on replacements for the Hard Stop Mounting Plates. The replacements will extend the plate back to support the PTO shaft directly above the gearboxes after said shaft was identified as a potential point of failure. The plates also include provisions for a new bar to mount the surgical tubing for the kicker on.

Later on in the day, the manufacturing team built two prototypes of aforementioned plates which will be installed and tested tomorrow.

Modified Kicker

Today the kicker plate was shortened. The shorter plate contacts the ball higher up on the ball, giving it a flatter trajectory. A rope was added as a hard stop, which prevents the kicker from contacting the roller system.

(There was a video here that has sadly been lost in the archives.)

(There was a video here that has sadly been lost in the archives.)

(There was a video here that has sadly been lost in the archives.)

Robot Shipped

As of 2:00 PM today the robot was delivered to drayage and confirmation of shipment has been sent to FIRST.

Robot Crated

The Robot Was Crated Tonight. Final Weights of Shipped Components:

- Drivebase (without cRio) – 52 lbs

- Arm – 19 lbs

The superstructure was withheld as part of the 65 lb withholding allowance.

Kickin Balls

(There was a video here that has sadly been lost in the archives.)

Feb 19 Progress

Today, we (almost) finished assembling the drivetrain and kicker winch gearboxes. We also made further progress on the bumper fabrication.

Here’s some photos to pass your time.

Bumpers and Drilling

Today progress was made on the bumper pieces, including machining the wood and corner brackets. We hope to finish the bumper structure by the end of Friday, to begin material cutting and sewing on Saturday. At this time, I do not expect the bumpers to be complete before ship, as the sewing is estimated to take a few days.

Tonight we drilled the arms to fit the bushings. Below is a picture showing the drilling operation.

Tomorrow we will begin assembling the arm, and make any necessary adjustments for proper fitment.

Manufacturing, Assembly & Field Construction Progress

MANUFACTURING

The manufacturing team worked hard today to machine the ratchets and finish the bar grabbing clamps. The lathe was also hard at work making spacers, standoffs and shafts.

ASSEMBLY

After the arms returned from the powder coat shop today, several members of the assembly team assembled one complete arm (minus sprockets which will arrive from anodize tomorrow).

FIELD CONSTRUCTION

The field construction team worked hard today to continue to carpet the bumps and other field elements. The field should be completed in the next few days.

More Progress

At the proving grounds, multiple teams worked on various parts of the robot to ensure that major components will be complete by the weekend.

In the design department, students and mentors completed the PCB design for both the gyroscope carrier and a revised LED driver. The PCB was sent to fab at 11:00PM. We will receive them Friday.

Down at the assembly line, students and mentors assembled major components in the drivetrain gearboxes. Unfortunately, the entire gearbox was not fully assembled due to the lack of a few components(PTO sprocket, gearbox standoffs).

Both robots’ wiring is almost complete. Tomorrow, we will complete the wiring by adding the 4AWG cables.

Effective Immediately

Due to a manufacturing error we are issuing an immediate recall of part no. 1010081. We apologize for the inconvenience this may have caused you. The part requires a bore to .722 in order to fit onto the 5/8 hex shaft. If you lack the tools necessary to carry out this change please notify us. We can be reached by post, phone, or email. Thank you again for your patience and understanding and as always, choose Team 254.

Bumper Fabric

We now have bumper fabric. The picture below shows the colors. The material and color looks great in person, better than the picture.

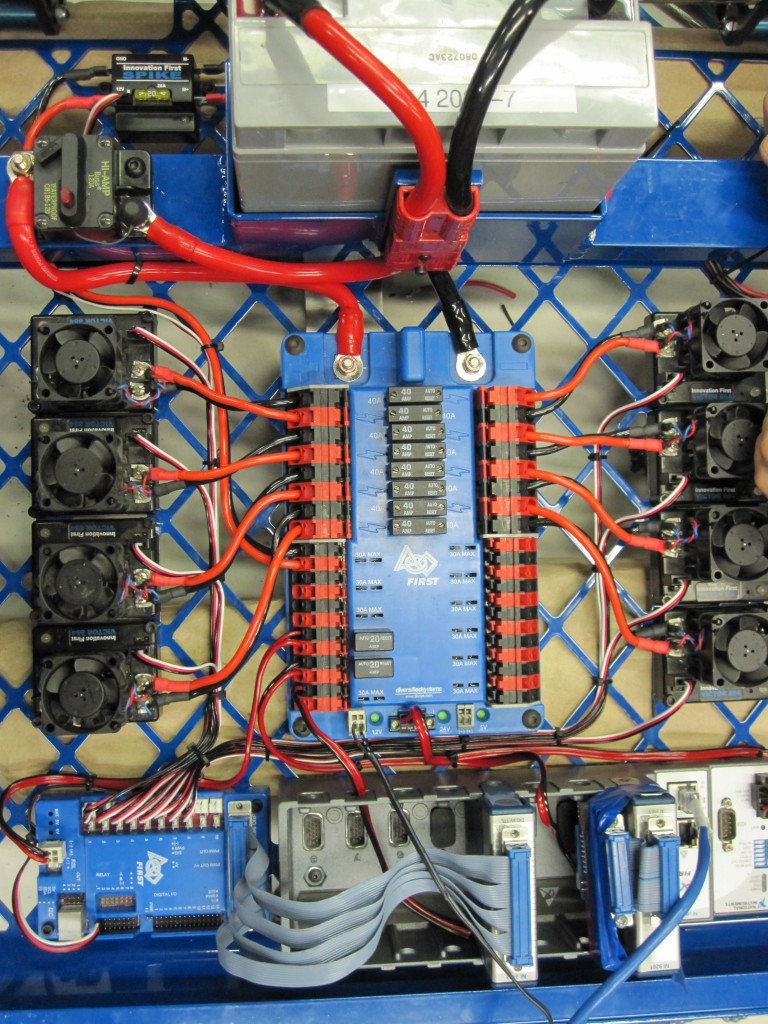

Robot Wiring

Today, wiring was done on the practice robot.

Today, wiring was done on the practice robot.

PWM Mapping

PWMs are labeled in a counterclockwise fashion, starting with PWM #1 in the upper left corner of the above picture and finishing with PWM #8 in the upper right corner of the picture above.

Bumpers and Control Boards Started

Today our procurement personell spent the day picking up several parts and materials, including plywood for the bumpers and switches, wire, and LEDs for the control boards. The plywood selected for the bumpers is a premium quality 12-Ply 3/4″ Russian Baltic Birch. The 5″ height blanks were cut today, and will be cut to length tomorrow. Below is a picture of cutting the bumper pieces.

The picture below shows construction and testing of the LED driver circuits for the control board.

Finally, we picked up the other two upper arm segments from welding. They are shown in the picture below. These are for 254.

Design, Manufacturing, Part Procurement, Crate Building & Field Setup Progress

DESIGN

The design is coming along and is almost finalized. The roller assembly is completely finalized and several small details need to be ironed out elsewhere on the robot.

MANUFACTURING

The manufacturing team worked hard today to produce several lathe parts including the drivetrain shifter shafts, the drivetrain shifter shaft spacers and the rear axles (which needed encoder holes drilled in them). The CNC team did plate work today, making the drivetrain piston mount plates and starting on the kicker plates.

PART PROCUREMENT

The [hopefully] last batch of parts from McMaster has been ordered, giving us the parts to complete our rollers. Two AndyMark orders have also arrived, allowing us to proceed on modifying the roller sprockets for transportation to 968.

PRACTICE FIELD SET-UP

Today, the lab contained a large group of students intent on completing important field setup tasks. The side borders have been setup and the towers have been placed in their final position. Some of the bumps are laid out but we are still waiting on carpet from FIRST.

CRATE BUILDING

The crate building team worked hard today to attach the last remaining side (the bottom) to the metal frame using wood screws. Several vinyl stickers were also cut and applied to the crate.

Arm Parts and Welding

After an all-night machining marathon last night, the arm parts were completed to be welded today. Our generous supporter Foes Racing was able to align and tack weld all the pieces into place this evening. Foes did the welding for the launcher and top arm in 2008 also. Below are some quick snapshots of the parts just before leaving Foes for the evening. The arm parts will be welded tomorrow night. Please take a close look at how everything is assembled, and quickly bring it to our attention if anything seems incorrect.

Efforts were made to align holes in waterjetted pieces with holes in the box tube pieces, and to ensure squareness during the tack-welding process. After welding is complete, a 0.875 reamer and a 1.250 reamer will be needed to enlarge the holes in the waterjetted pieces. Additionally, all threaded holes still need to be drilled and tapped.

Field Parts Have Arrived!

The official FIRST field components arrived today and were taken inside to be inventoried (and played with).

Field setup will begin in the next few days, as soon as we determine which building we will be setting it up in. If you get the chance, please thank Mark Leon and NASA for their generosity and support in getting us these field components. Please remember; we were lucky enough to receive these field components with the understanding that we would open our lab up and invite the other Bay Area teams to utilize it whenever possible. Let’s make sure we are gracious and welcoming hosts when they arrive, and that we fully understand how lucky we are to have the opportunity to help everyone out. We also need to take care of these components and keep them nice, as we can expect to use them at all of the local scrimmages and events that require a full sized field.