Blog - 2010

Wheel Design

The wheel design has been completed. The wheels weigh 0.30lbs each and construction will begin tomorrow.

Manufacturing Progress

Today we finished the first operation on all 140 bearing housings. We began machining the backsides of them and expect to be finished tomorrow evening or early Friday, at which point we will begin machining wheels.

Build Day 4

At Team 254’s lab today, we had an extremely large number of people working hard to complete some common objectives.

In the manufacturing department, several students continued cutting stock for the bearing blocks. Many of the bearing blocks have already completed their primary operation on the CNC mill.

In the design department, a very large group of students worked downstairs all afternoon to continue to develop prototypes for ball launching devices. Some have been modified and improved to be tremendously more powerful than their previous states. Upstairs in the CAD department, a small group worked hard all afternoon to CAD the Drive Gearbox. As of 10:00 PM, the gearbox shafts are mostly done, but still need to be toleranced, which will be completed tonight to finalize the shaft drawings. In the morning, the drawings will be sent to 968 and Pacific Precision for the shafts to be completed this week.

This week, the design team will finalize the gearbox and design the drive wheels so that the gearbox plates can be manufactured by Team 233 in Florida. The manufacturing department will continue to manufacture the bearing blocks and will move on to the wheels once the bearing blocks are completed.

Winch Gearing & Performance Calculations

See the linked PDF below, for some important calculations regarding gearing and performance of the winch. The run-through of the basic calculations should be understandable by the astute high-school student.

Please let Dave know if there are any errors in the calculations, and it will be corrected accordingly.

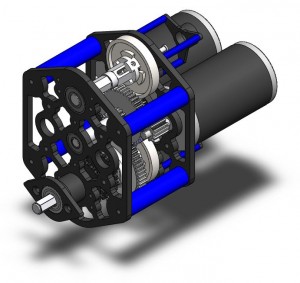

Final Ratios & Gearbox Info

Agreed Upon Specs:

2 Speed with Power-Take-Off (PTO) for Winch

4 CIM motors, 2 per side

Initial Reduction – 12:45

High Speed Reduction – 30:48 gives ~15.5 fps at 93% efficiency

Low Speed Reduction – 14:64 gives ~ 5.5 fps at 93% efficiency

All gears are AndyMark except for the 64 tooth dogged gear, 45 tooth intermediate gear, and the 30 tooth internediate gear, all of which are standard Martin gears.

The PTO shaft sits above the intermediate shaft and has one speed, and an the option for two with the addition of another three position piston. We also have the option of disengaging the output to the wheels if we use another three position piston.

Options Clarified:

1. Wheels move when winch is engaged – two standard pistons required per gearbox

2. Wheels do not spin when winch is engaged – one standard piston, one three position piston

3. Wheels spin when winch is engaged, but winch now has 2 speeds – one standard piston, one three position piston

4. Wheels do not spin when winch is engaged, and winch has 2 speeds – two three position pistons

The cost of the three position pistons is ~$70. The cost for the standard piston is ~$20. The gearbox will be designed to accommodate any of these options without the need to change ratios, plates, shafts, etc.

Ball Launcher

(There was a video here that has sadly been lost in the archives.)

Angled Tests

(There was a video here that has sadly been lost in the archives.)

8 Wheel Drive Tests

(There was a video here that has sadly been lost in the archives.)

Wheel over bump storyboard

Check out the different positions as these configurations go over the bump.

Build Day 1 Meeting Minutes

- Ideal design would utilize a rigid 6 wheel / 8 wheel structure

- Ideal design would also incorporate a mechanism that will allow the robot to traverse over bumps quickly

- Both teams are wondering on the usage of 8″ inch wheels. (Additional gearing)

- Recommended Protyping: Build 6″ wheel chassis on 6 wh/8 wh base

- Didn’t discuss ball manipulation mechanism

- Winching should be relatively easy

- The transmission should be the most important part of this game

- 254 disagrees to lifting up two other robots(Reasoning: 50 lbs of parts for 6 points)

- 254 recommends that we should winch ourselves

- 254 will test 8″ and 6″ diameter wheels on 06 bot.

- 968 will do CAD on wheel base distance with various wheels and distance from center to center.

Build Day 1

After returning from our Kickoff meeting at Bellarmine, Team 254 returned to the lab to start field construction. We sorted through the carpet to find the biggest and least worn continuous pieces and lay them out. They were then seamed together with carpet tape.

We also constructed one of the field “bumps” from the official FIRST drawings using 3/4″ plywood. We then proceeded to place different configurations of wheels on robots and roll them, unpowered, over the bump.

We’re currently looking into building a powered drive train for 8 wheels with rigid frame rails for additional testing.