Blog Archive

Day 41: Chairman’s Submitted and All Parts Back

Chairman’s

Today, our Chairman’s Submission was published. You can read it here. The Chairman’s Award is FIRST‘s highest honor, celebrating excellence as a whole team in addition to success on the field.

Assembly

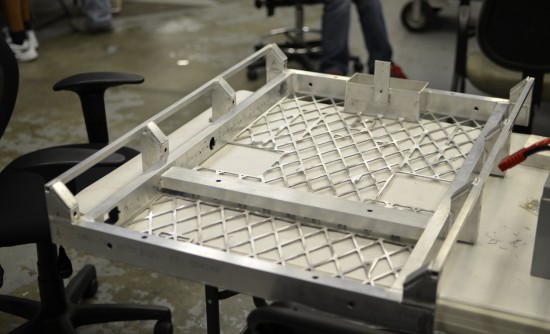

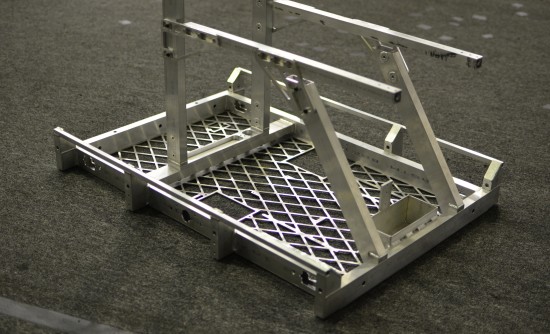

Today, we got the last batch of parts back from the powder coater. At this point, all parts have returned from their respective sponsors. Assembly has started and will continue tomorrow.

Scrimmage Preparations

Unfortunately, our practice field has gotten stuck in Chicago and got slightly delayed. Due to the generosity of NASA, our title sponsor, the field was expedited and will be here between 5AM and 7AM on Saturday. We will need to work extremely hard to get everything ready for the scrimmage.

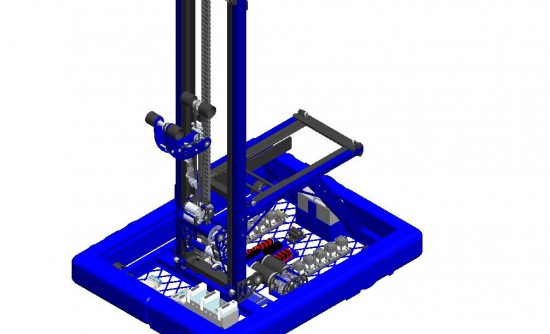

Day 40: Elevator

Today, the elevator worked for the first time. It is extremely fast. We are taking the final batch of parts to the powdercoating shop in the morning.

Day 39: Meetings

Today, we had our whole team meeting at the lab. Many team members and parents came together to discuss the robot and preparations for this weekend’s scrimmage.

Animations

The VEX Animation was submitted Saturday.

See it here:

//www.youtube.com/watch?v=fH983bEvpYY

The FRC Animation is being uploaded as I am posting this.

See it here:

Day 38: Machining, Wiring & Pneumatics

Machining

Today, the machining team worked on the elevator second stage top and bottom caps. The bottom caps are complete and the top caps are in progress.

Furthermore, on the lathe, we worked on various spacers and shafts.

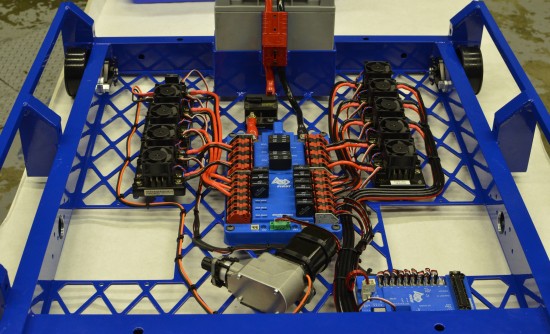

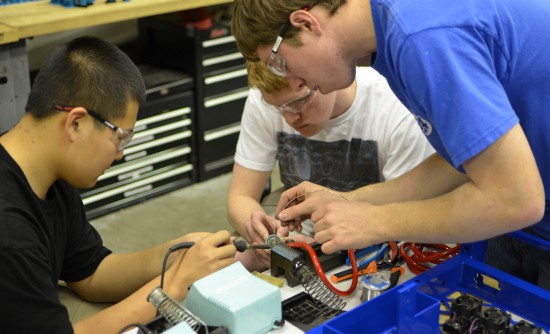

Wiring, Pneumatics & Programming

Today, we finished (except for sensors) wiring the bases on both robots. Our second cRio arrived and we flashed it, allowing us to run both robots simultaneously. We plumbed the pneumatics on the base of both robots and ran a pneumatics test on the practice robot. After fixing several leaks, the system is good to go.

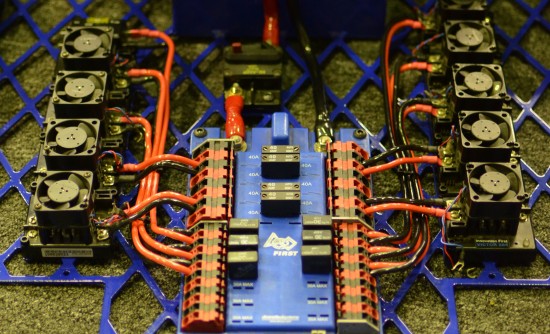

Control Boards

Today, we got the control board back from the CNC routing sponsor. The next step is assembly.

Days 36 & 37: Driving Robots

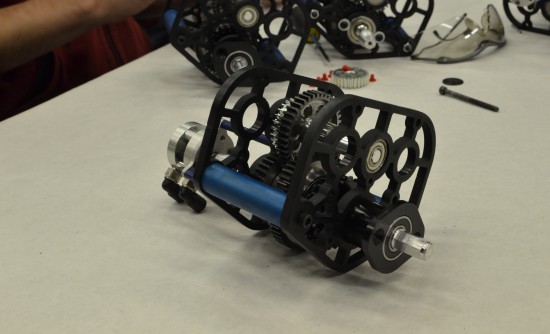

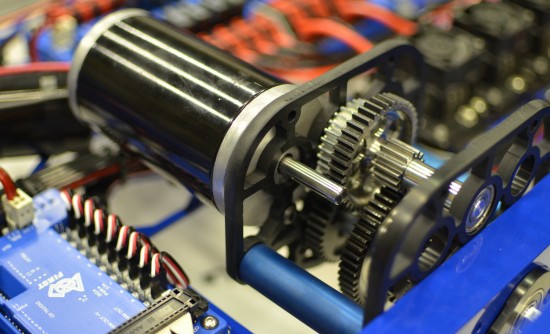

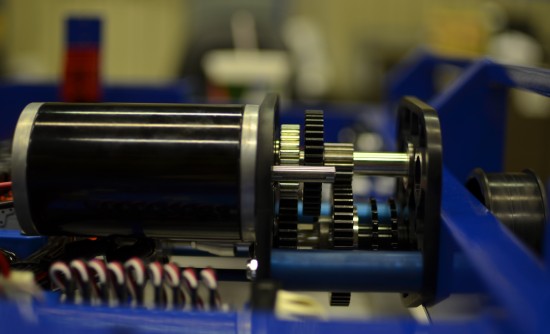

After countless hours of gearbox building, wiring and troubleshooting, the practice robot is finally driving. Furthermore, we have assembled one set of bumpers.

Day 35: Gearboxes, Field Trips, Bumpers and More

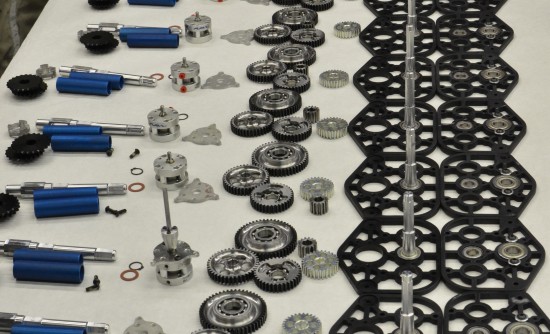

Today at the lab, we got our parts back from the anodize shop which allowed us to finally start assembling gearboxes. Everything looks great and this task should be finished in the next few days.

On a separate note, we had several FIRST Lego League students who came to tour the lab today.

Also today, the manufacturing and assembly teams were hard at work finishing the bumper frames. We will wrap fabric on the bumper frames tomorrow to hopefully finish the bumpers.

The minibot team has just about completed the CAD model of the final minibot. The design is now due for review and manufacturing in the next few days.

Day 34: Manufacturing, Programming & Bumper Assembly

Manufacturing

Today, the manufacturing department was hard at work finishing most of the parts for the bumpers and working on the shifter dogs and minibot deployment rail end caps. We hope to have every machined part done by Monday.

Programming

The programming team has been busy over the last few weeks perfecting teleoperated drive code. Using a mix of linear, exponential and logarithmic functions, they have refined Onslaught’s teleoperated control.

Bumpers

The bumpers are coming together. Today, we put all the steel nut plates onto the bumpers and cut pool noodles to length. They should be completed tomorrow.

Day 33: Manufacturing

Today, we continued to work on manufacturing many of the primary parts for the robot. The dog gears were started and are coming along great. Furthermore, the bumper corner pieces are completed leaving the bumper pins as the only pieces remaining to be able to finish the bumpers.

Day 32: Manufacturing

While we are waiting for parts to return from the andoize shop, we have been doing a ton of manufacturing. Today, we finished lightening all of the robot’s gears and finished milling bumper wood. Furthermore, we cut the steel bumper pin mount pieces and worked on shafts and spacers on the lathe.

Day 31: Wiring & Manufacturing

Wiring

Today, we continued wiring the robots. The competition robot is coming along nicely and is nearing completion. It should be completed in the next few days as soon as our remaining orders come in.

Manufacturing

Today, the CNC team was lightening gears and cutting dog teeth into the shifter gears. On the lathe, several team members worked tag-team all day to keep the machine running constantly while making spacers and shafts.

On the mill, we were working to turn out the wood backings for the bumpers which should be completed tomorrow so that bumper assembly can proceed. We also received the bumper fabric back from embroidery today.

Days 29 & 30: Wiring Weekend

First of all, I apologize for not putting a post up last night. I got home late and forgot to grab pictures off the camera before leaving and thought that a blog post without pictures might be a bit boring.

Anyway, today was our big weekend of wiring the robot. After countless man-hours of work put in by many dedicated team members, the practice robot wiring is complete and the competition robot is half-way complete. We are still waiting on some components to mount on the comp robot electronics board before we can finish wiring.

On Sunday, we were able to successfully test all of the speed controllers and relays on the practice robot.

Machining is coming along well too. The gears for the gearboxes are almost done being lightened and we are sending out many parts to anodize in the morning.

The programming and controls team has been hard at work. We have put together joysticks for the control board and have worked to put provisions into the code for the control board.

Day 28: We Have Robots!

Today, we got parts back from both the anodize and powder coat shops and began assembling and wiring the frames. Our sponsors are the best, allowing us to get frames powder coated in 1.5 days so that we can catch up on our schedule.

Animation Status

Currently we have finished all the scenes of the VEX animation besides the last one of the gameplay. We will render the 3rd through 5th scenes of the animation tonight and have them all posted to the Dropbox in the morning.

The gameplay scene is being finished by Johnathan Chang as I am typing and will be completed and rendered by Sunday morning.

Bhargava Manja will record all of the voices for the scenes we have rendered by tomorrow.

Erik Anderson will have the music done Saturday.

Day 27: Prototyping, Manufacturing & Design

Prototyping

Today, the prototyping group worked on their minibot design. The minibot is coming together. However, we have hit a setback in that one of our motors has burned out and we need a replacement.

Manufacturing

The manufacturing team was hard at work today machining a number of plates and lathes for the robot.

The robot frames were dropped off at the powder coat sponsor early this morning and should be completed tomorrow.

A team of students marked out the locations for the embroidered team numbers on the bumpers. They will be embroidered beginning tomorrow.

Design

Today the design team worked on the design for the bumpers and the control board. We are hoping to get the control boards cut on a CNC router but are looking for potential sponsors.

Day 26: It’s Beginning to Look like Robots

Manufacturing

Today, we received all of our parts back from the welding sponsors. All of the welds look great and beautiful and we were able to begin assembling parts. The frames are being brought to the powder coating sponsor early in the morning and will be powdercoated soon.

In other news, manufacturing and prototyping continued and we got a shipment of parts in today. We hope to finish machining in the next week.

Day 25: Manufacturing, Prototyping, Whole-Team Meeting

Manufacturing

Manufacturing is really in full swing in N246. We are churning out new parts every hour and the horizontal bandsaw hardly stopped cutting stock today. We should have a productive week ahead.

Prototyping

The minibot prototyping group continued to prototype their minibot design using several custom-built parts. The prototype is not yet complete.

Whole-Team Meeting

Today was a whole-team meeting and parent meeting at the lab. We met to get status updates from each subgroup captain. The meeting went awesome.

Day 24: Manufacturing, Prototyping & Programming

Manufacturing

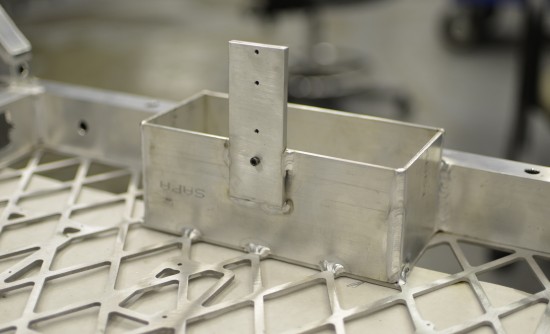

The manufacturing team was hard at work today on the mill, lathe and CNC mill. We made countless shafts and spacers, several major CNC’d parts that need to be powdercoated and worked on endcaps and the elevator second stage side rails on the manual mill.

Design & Prototyping

The design and prototyping groups were busy today working on their iteration of the minibot design. With this design, they are trying to make the robot as lightweight and fast as possible utilizing several minibot-legal custom parts including a sheet metal frame. The prototype was not yet completed.

Programming & Controls

The programming & controls team was working on a number of tasks today including preparing our new Custom Controls Interface for interfacing with the software. Furthermore, they are working on the simulator and working to setup the new 2011 wireless bridge.

Day 23: Day Off

Today was our second day off of the season. We’re trying to take Sundays off so that team members have time to get all their homework done and just take a break from robotics.

Although there was no regular meeting at the lab, our sister team 1868 was meeting, so the mentors were still in and the CNC machine kept running. The arm tubes were completed today and will be ready for welding tomorrow.

Day 22: Programming, Prototyping, Manufacturing

Programming

Today, the programming team was hard at work on a number of projects. Their PID control of the robot is starting to work aweseome and the robot is at the point where it can traverse the whole field while only turning 1° (this translates to a ~1″ left-right difference from perfectly straight)

Furthermore, Daniel was able to implement motion control as a new method of controlling the robot. Using a PS3 controller, he has full control of the robot’s drivetrain, as demonstrated in the video below.

Prototyping

The prototyping group was hard at work today working on a completely new minibot prototype. After a review of the engineering design process, they worked on a new design that should deploy onto the pole even easier than any of the other prototypes. The design is slow and climbs the pole in about ten seconds, but is a step forward as far as deployment goes.

Manufacturing

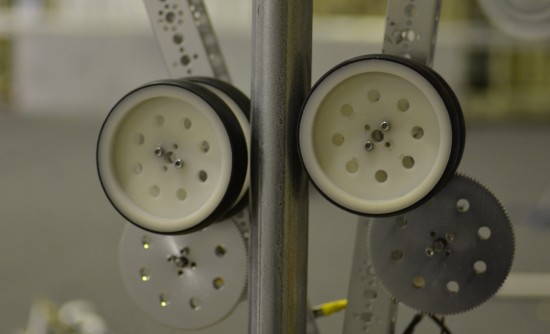

Today, the manufacturing team was working on a number of parts. They finished the carriage bearing blocks and grabber piston mount pieces. Furthermore, the group was able to machine the short plugs for the arm pivot tube and the arm pivot tubes. Finally, they turned the polycarbonate spool body for the elevator spool.