Blog - 2010

Control Board Progress

Today we were able to cut out the polycarbonate for a control board on the CNC router at Glendale Community College. It took much longer than expected, due to the polycarb melting at any feed rate over 18 IPM, even with a constant cool air blast on the endmill. Machine setup took about 75 minutes, and fixturing, cutting, and removing the panels took about an hour. Tomorrow evening we will finish cutting the second board. Below is a picture of the assembled control board.

Weekend Progress: Update

The manufacturing department was very understaffed today due to the superbowl(I guess?)

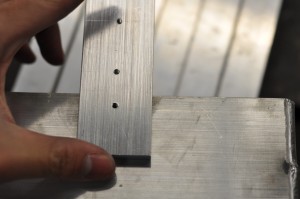

We’ve completed the milled slots on the 1 x 2 Arm sides(1010084)

Weekend Progress

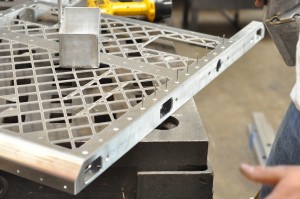

Manufacturing:

Tonight we completed the four piston bearing blocks (1010073) for the kicker winch. These took much longer than anticipated using manual machines. Below is a picture of the completed parts:

For the small piston bearing blocks (1010019) we hope to have a CNC lathe available tomorrow evening. Tomorrow we hope to cut out the control boards as well, on a CNC router.

The 1 x 2 x.125 box tube parts for the arm structure have been cut, and are currently undergoing milling and drilling operations, and preparation for welding this week.

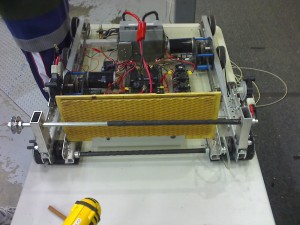

We have robots.

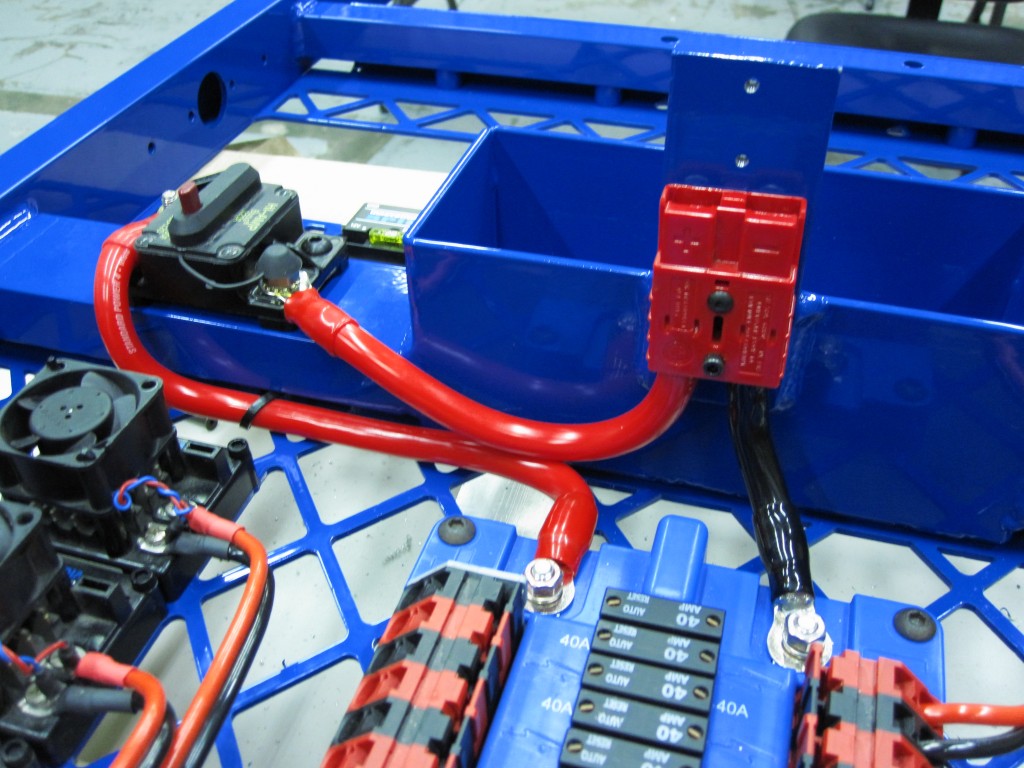

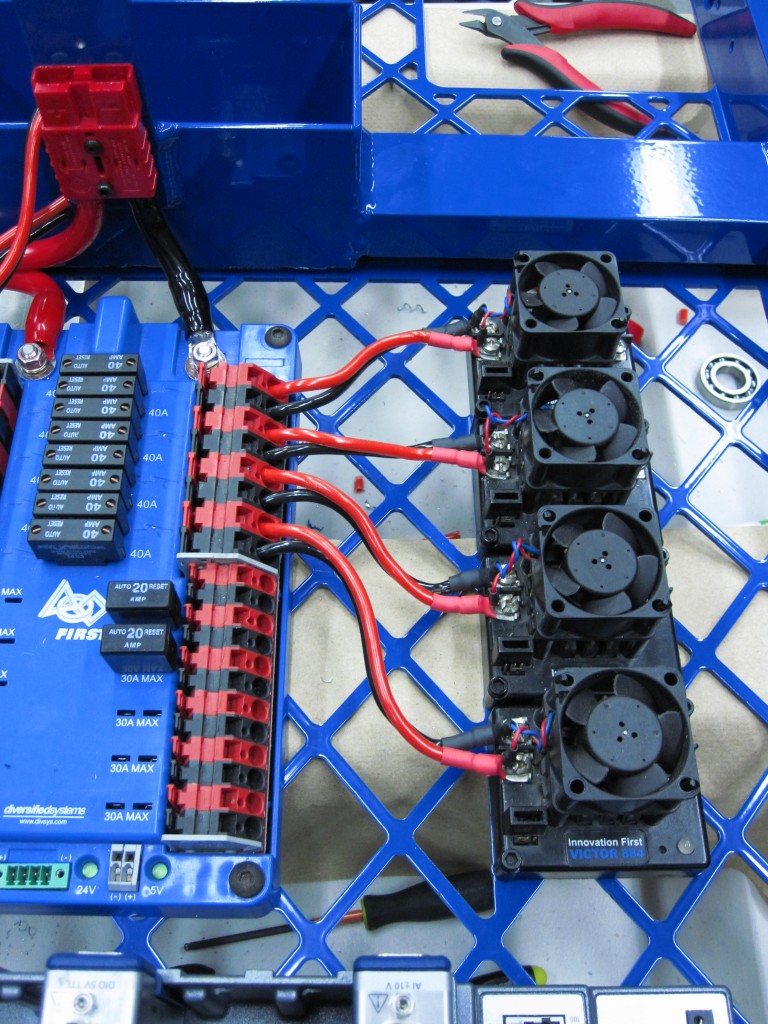

After receiving our frames very late last night, we began wiring today. We mounted all of the electronics and ran the 4 gauge primary power wires.

We then proceeded to run wires for the Victor 884 speed controllers. After several separate configurations, the most popular involves running each Victor power wire independently and not zip-tying them together at all.

Besides working on the frames, the manufacturing department continued to lathe a myriad of spacers and standoffs for the kicker and drive gearboxes. The CNC was working hard all day to cut dog ridges into our two separate dog gears and the dog lock plate.

A large group of students also worked hard all day on 254’s crate, ending with painting it.

Bumper Mounting and Control Board Parts

Today we completed the 32 bumper mounting pins and brackets, and 20 control board spacers. The bumper mounting scheme is nearly identical to the 968 2009 bumpers. The finished parts are shown below.

Next, we hope to cut the control board polycarbonate on a CNC router, and machine the piston bearing blocks (cones) on a CNC lathe. Additionally, we will be cutting the 1×2 box tube parts needed for the arms.

Closer to Completion

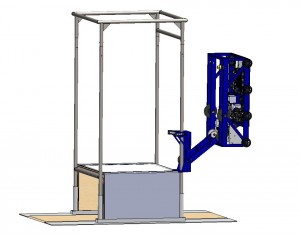

Design: The team has finalized CAD designs for our kicking device and has finalized all mechanisms.

Parts: A set of manufactured parts has been sent to our sister team, 968.

Manufacturing: We are continuing manufacture of dogs for our kicker shaft.

Design: T-shirt designs finalized!

In short, 254 is well on its way to finishing the robot (name TBD)

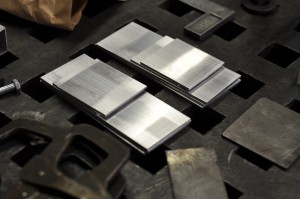

Finished Parts

Here’s a picture of everything completed so far (Minus gearbox plates and sprockets, which are out to anodize, and frames).

We haz powdercoat.

We haz powdercoat.

Unfortunately, Central Powder Coating was not well staffed today. They will have the 254 frames powdercoated blue streak #2 tomorrow morning.

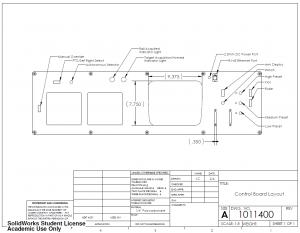

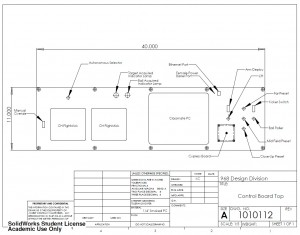

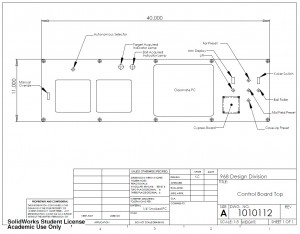

Revised Control Board Layout

This revision includes the cutout for the Classmate pc, contours and filets for the ethernet jack, holes for the LED mounts, screwdriver slots for the Cypress board and finally, an additional cutout that replaced the roller button.

Progress

Manufacturing

Pacific Precision is able to make the output shafts; unfortunately they will not be done until late next week. We also confirmed that the robot frames will be ready to be picked up from Central Powder Coating at the end of business day Thursday. We continued progress on machining the bumper mounting pins, and will begin on the kicker piston bearing cones once the bumper mounting parts are complete.

Design

The control board CAD is being revised and we purchased all of the components for the boards.

Other News

We secured a local embroidering shop to make the team numbers on the bumpers.

We have contacted Motion Industries for a quote for all the ball bearings, and are currently awaiting word back.

Progress

MANUFACTURING

The manufacturing team has been working hard to complete parts for the drivebase. After completing gears and sprockets, we have moved onto the construction of the shifting dogs for both the drivetrain and the kicker winch.

DESIGN

The design team has been working to finalize a myriad of parts so that manufacture can begin. The plates for the kicker winch and arm have been finalized, and will begin being waterjet at BAE Systems tomorrow after the material is delivered. Design on the rollers is continuing, implementing the Clutch that we have purchased from McMaster-Carr.

Welding Complete, Off to Powder Coat

Today the welding was completed at Ride & Show Engineering, and the frames were delivered to Central Powder coating. The picture below shows us with the kind folks at Ride & Show.

Control Board

Update: Here’s the newer revision of the control board. I’ve added an ethernet port and a female barrel plug for the Classmate PC.

Here’s the first revision of the control board with a suggestion of buttons and functions.

We will be using this LED w/Defuser(Red and blue??)

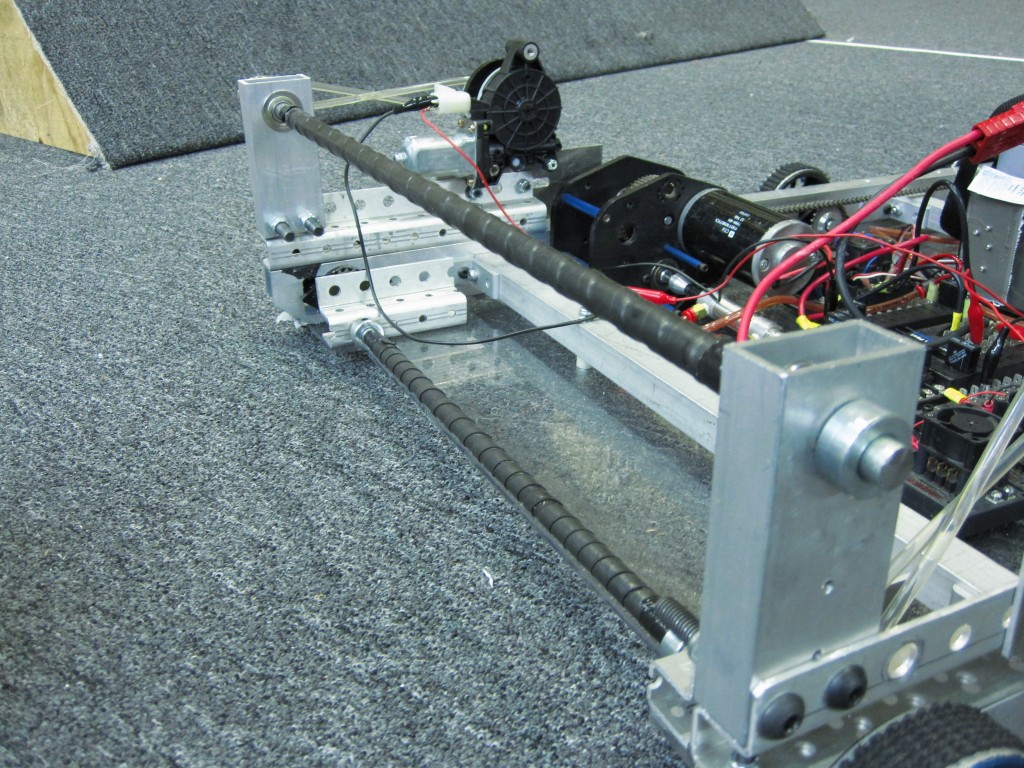

Roller Prototyping Progress

Today, we continued prototyping dual roller systems. We worked hard to emulate the drawings we had, but still found minimal success with the belt-driven systems. The faster the rollers were moving, the better the results. However, if the rollers were moving too fast, the window motors would stall and be damaged.

At the end of the evening, we strapped a Dewalt 3 Speed Drill onto the robot. With the shifter on middle or high speed and the clutch set very low, we were able to obtain and hold the ball extremely well. Videos of this system at work are below.

(There was a video here that has sadly been lost in the archives.)

(There was a video here that has sadly been lost in the archives.)

General Update

We continued to revise the two horizontal-rollers prototype so that it would be ready for proper implementation on the final design. Some of the most recent changes made include a stop, so that the ball is physically limited from entering more than 3 inches into our robot. Unfortunately in the earlier tests the ball actually entered 4 inches into our robot and roughly 1/16 inch off the ground. We also shifted the upper roller as forward as possible while retaining space for the bearing and moved the lower roller forward. The roller speed was also increased from the window motors with a 4 to 1 pulley reduction Videos should follow tommorrow after the design is perfected further.

Down in the shop we continued to pocket gears on the CNC and several sets for both the drive-train gearbox and the shooter winch gearbox have been manufactured already. Hopefully by the end of tommorrow we will be for the most part done pocketing the gears (at least the ones finalized on the design). They will be ready for ship by Monday or Tuesday.

Prototyping Progress

Dual horizontal rollers with tennis racquet grip tape = money.

Team 254 finally finished the initial prototype for dual horizontal rollers this evening (Based on 148’s prototype) and after much tweaking we found that the rollers held the ball securely and within the limits of the rules. The mechanism uses two small window motors running continuously (at least in this prototype), and it has little difficulty with picking up a ball on the go. For a final design, the rollers should spin faster to ensure that the ball is picked up 100% of the time, and actual placement of the rollers will need to be tweaked to perfection.

(There was a video here that has sadly been lost in the archives.)

(There was a video here that has sadly been lost in the archives.)

On the third day…

After calling many fabrication shops in Southern California within a radius of 45 miles, we ended up at the California Polytechnic University, Pomona shop. Our metal forming division was lucky enough to find the proper die to create the 45 degree bends on a 100 ton press brake. Setting up the machinery and completing the bends took 6 hours.

Our newly acquired sponsor, TOMCO Products in Azusa, was able to perform the 90 degree bends with a very quick turn around.

Below are our newly trained press brake operators holding the first bent plate

Here’s one of our highly skilled operators hard at work(or hardly working)

Here’s a plate being formed

Here’s another photo of a plate being formed

Here’s our assembly and inspection division test fitting the formed pieces

Here’s where Jesus joins metal with all his might

(There was a video here that has sadly been lost in the archives.)

Oh, and uhh.. here’s the current status of the parts:

We currently have one fully welded base, two tacked bases, and one base waiting to be welded.

Jesus needs to take a break, so, he’ll be back on Friday to complete joining metal.

Finally, below is an artist depiction of our team’s weekly activities courtesy of our comic division:

The work of Jesus

Today, the battery boxes and superstructure sides were welded. We’re attempting to bend the base plates before we go ahead and begin to weld the drive base.

In the meanwhile, here’s some photos of Jesus and his special touch.

Jesus welding a battery box

The completed welds on the superstructure sides

Here’s another shot of the superstructure sides

Here’s the battery box plates before they’re welded.

Attempting to center the battery connector tabs

Here’s the jig that we used

Here are two almost-complete battery boxes(tack welds need to be filled in)