Blog Archive

Day 4: Field Construction, Whole Team Meeting

Field Construction

The field construction team made huge progress today. A large group of students worked hard all day to complete both the minibot pole and one grid of scoring pegs.

Whole-Team Meeting

We had a whole-team meeting at the lab today. We discussed the progress thus far in the season and decided on distinct mechanism groups that will work on prototyping and designing each mechanism. The slides are shown below.

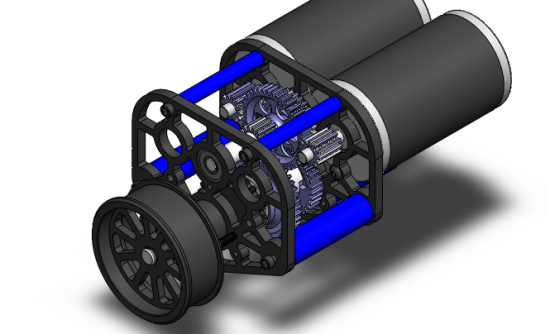

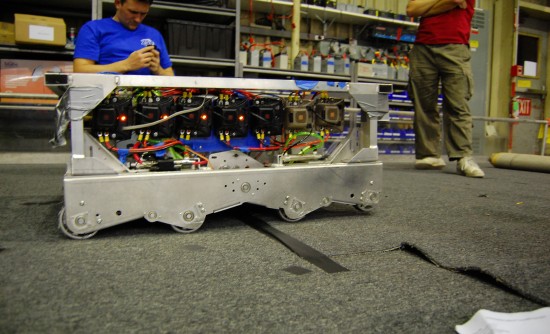

Mechanism #0: Drivebase

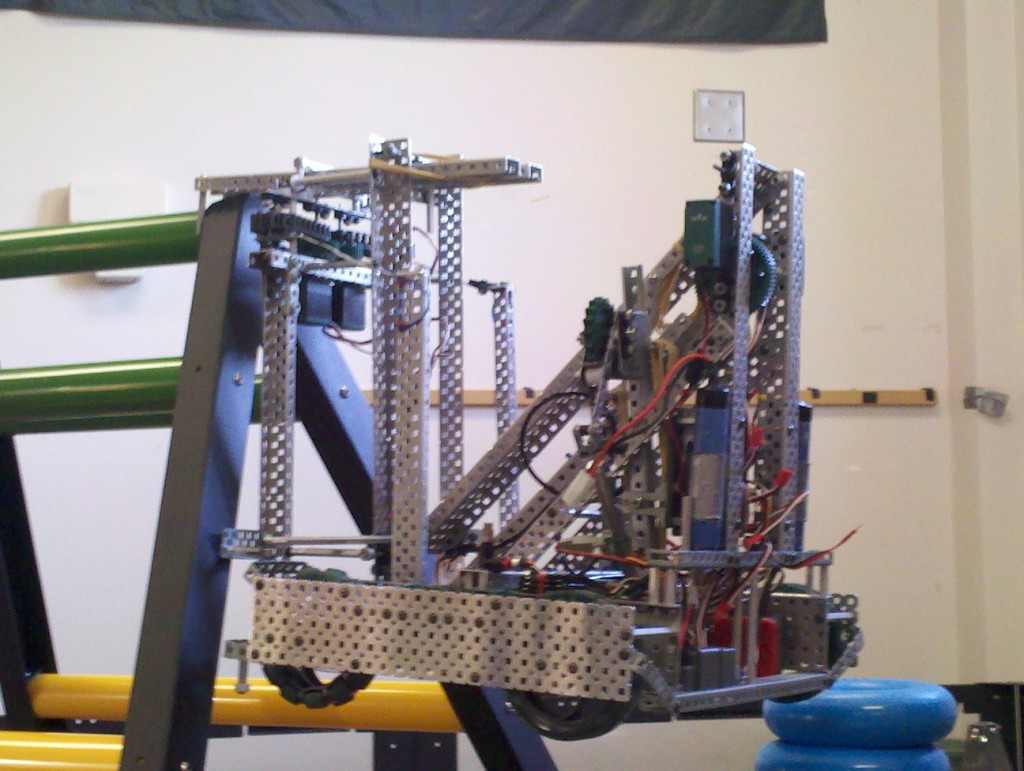

Mechanism #1: Elevator/Arm to lift tubes to scoring height

Mechanism #2: Tube Grabber

Mechanism #3: Minibot

Design

The design team did not work very much today. After the whole team meeting and the field was completed, we met to discuss the benefits of elevators and arms for mechanism 1. Although no decision was made, the group seems to be leaning towards elevators for several reasons.

- We are very familiar with elevator design.

- Elevators can be extremely fast

- Precise height positioning is easier with elevators.

Here is a video of our 2007 robot and its clone, team 968, and their elevators. Although our grabbers for this year may very drastically from their grabbers, the video gives a sense for how fast these elevators can move. The elevators are able to easily move to any position in less than a second where most arms would take more time to raise a game piece.

Day 3: Field Construction, Programming, Design & Manufacturing

Field Construction

The field construction team was hard at work today working on the two elements of the game field that we are building this week. We have constructed a shopping list and hope to buy the remaining materials tomorrow.

Programming

The programming team was working hard today on teleoperated and motor control code. They have designed an interface to separated the control system (joysticks, arrow keys, etc) from the code so that the robot can be easily modified to be driven by a variety of controllers. Furthermore, they performed experiments to measure how linear the Victor Speed Controllers are in their outputs. Using MatLab, they will be able to analyze this data and derive a function to linearize the Victor outputs.

Design

The design team was hard at work today. The first order of business was the drive gearbox. After the gear ratios were finalized last night, we were able to move forward with the drive gearbox CAD which his now completed. When doing the design, we were able to develop a new way of retaining the shifter shaft between the bearings to ensure that we can shift reliably. Without motors, the wheel and bearing housing, the gearbox is less than two pounds.

In addition to working on the gearbox, a group of students worked to design and CAD the drivebase frame. After careful review of the bumper rules, we decided on a design that would support the bumpers all along the back while still being extremely lightweight. We added a heavily pocketed baseplate and put the whole thing together for a design that weighs about 30 lbs.

Manufacturing

Production continued on the first operations of the bearing housings. We hope to finish the bearing housings by Wednesday.

Lab Improvements

Today, the wired network between the lab computers was completed so that they can all share printers.

Day 2: Drivetrain Design & Manufacturing

Today, at the lab, a group of team members met to continue designing the robot drivetrain and continue manufacturing bearing blocks.

Networking & Lab Improvements

We started by networking all of the upstairs computers at the lab together. This will allow us to share printers before the computers. We were able to connect all of these using a switch generously donated by our sponsor, Vivid-Hosting. The networking will be completed tomorrow.

We also procured two power strips which were wired under the floor to provide power to two upstairs tables for laptops. Previously, the lab did not have a good place for laptops to work.

Manufacturing

Manufacturing on the bearing blocks continued today. Progress is being made and the manufacturing will continue into the next few days.

Design

Today, we discussed and decided on several key aspects of the drivetrain.

The first topic of discussion was wheel size. Several team members brought up the idea that with such a flat game field, we could potentially go to wheels even smaller than 4″. Although we quickly ruled out 3″ wheels due to lack of ground clearance (~1/4″ clearance), we were interested by the prospect of 3.5″ wheels which would lower our center of gravity slightly and could decrease drivetrain weight by more than one pound. Furthermore, because less gear reduction is needed with smaller wheels, the weight of the spinning components could be decreased by up to 20%, leading to a potential significant increase in robot acceleration. However, some team members had reservations due to the decreased ground clearance in the move from 4″ to 3.5″ wheels.

To come to a consensus, we created a weighted objective table to weight some of the pros and cons of each design. After much deliberation, the table resulted in almost a tie so we continued to discuss. In the end, it was decided that any problems caused by the decreased ground clearance (1/4″ lower) of the 3.5″ wheel system could be avoided so we decided to move forward with the lighter 3.5″ wheel design. This caused the outer bearing blocks to need edits so that they would not interfere with the newer, smaller wheels.

Benefits of 3.5″ Wheels

|

Benefits of 4″ Wheels

|

The second topic of discussion was robot speed. After yesterday’s strategy session, the whole team was in agreement that having a fast and maneuverable robot would be key to successful performance in Logomotion. After deciding on small, 3.5″ diameter wheels, we also knew that these smaller wheels would not require as large of a gear reduction as has been present in past robots.

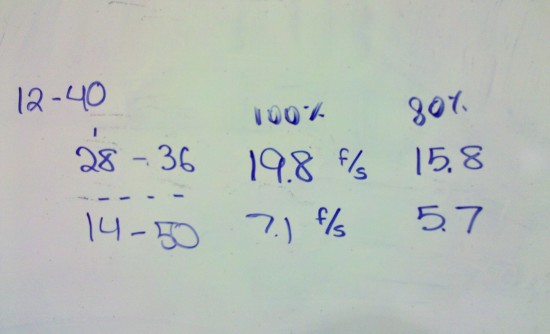

With the ability for a smaller gear reduction, we started with our gear ratios from last year and worked with them to both speed up the robot and minimize the use of large gears to decrease robot mass and increase acceleration. In the end, we found a set of ratios that we liked that will both allow for the fastest 254 robot ever built and for smaller and lighter gears while still maintaining a slower low gear.

Finalized gear ratios for the 2011 robot. Robot speeds are estimated for 3.5" wheels in ft/sec at 100% and 80% efficiency. The first line represents the common reduction. The second and third lines correspond to the secondary reductions for High and Low Gear.

Finally, today was our deadline to finalize the gearbox shafts to be sent out for manufacturing by sponsor Pacific Precision. All four of the shafts were updated and finalized by a team of students. All drawings were checked by team leaders and mentors and were sent to manufacturing.

FRC Season Day #1

Today was an extremely productive day at the lab. We built a significant part of the field, tested the game elements, began design, started manufacturing and continued to work on programming.

Field Construction

As soon as we got to the lab, a large group of team members got started building a replica of the most essential field elements – a rack and a tower. We intend to build enough of a low-cost field for testing and the NASA Robotics Alliance Project will purchase a complete field for the west coast in the coming weeks. The field will stay at our lab during the build season but will travel around the state for various off-season competitions afterwards.

Game Element Testing

After we had a basic understanding of what the rack was going to look like, we moved forward with game piece testing. We experimented with how far the tubes could be thrown and discovered that a well-trained human player could likely throw tubes across the entire field.

Programming

The programming team was working hard all day. They began the day by installing the new versioins of the programming software and then spent the day getting Onslaught to drive under driver control. The simulator group was working on data logging, 3d modeling and collision detection.

Design

After dinner, a group of team members met to discuss robot design. We immediately decided on a wheeled robot and decided that at least 6 wheels would be best for maneuverability. To save weight, we all agreed that it was not practical to consider building a robot with more than 8 wheels. We also decided that we would like a two-speed drivetrain with a high gear to quickly traverse the field and a low gear to push other robots out of the way if necessary.

When looking at the game field, we were very worried by a 1/4″ tall plate under the carpet surrounding each tower. The concept of a 6 wheel drive or 8 wheel drive drivertrain with dropped center wheels relies on the fact that not all of the wheels will be on the ground at all times to improve turning. We were worried that when in proximity to the plate under the field, more wheels would be in contact with the carpet which could inhibit turning. We thought that this might be a greater issue with the six wheel drive robots than with eight wheel drive robots, but decided to test to make sure.

We put down a metal plate under carpet and tested it with both 8 wheel drive and 6 wheel drive robots. It was determined that the 8 wheel drive robots drove considerably better when in proximity with the plate when in high gear. However, in low gear, both robots had great performance as if the small bump wasn’t even there.

We took the data from our tests and moved on to discuss how important turning near the towers would be in high gear. It was determined that the only time turning near towers would be very necessary is when lining up to deploy the Minibot. We decided that this is only for about 5 seconds of the match and that there is no reason to not just use low gear during this time.

After we decided that it was not important to be able to turn in high gear near the towers, we all decided to move forward with a six-wheel drive robot. Everyone in attendance voted that the benefits of saving up to 3 pounds outweighed the drawbacks of potential limited turning in high gear when in close proximity to the towers and agreed that a six-wheel robot would be best.

The next topic that was discussed was traction. Although with ideal physics, contact area with the ground does not affect traction, it was determined through observation that due to the tread material interlocking with the carpet fibers, more contact area does indeed result in greater traction. Because of this, we discussed moving to slightly wider wheels in order to increase the contact area with the ground. We were worried that wider wheels could negatively affect turning so we decided that the robot should be designed with thin wheels (similar to what we have used before) but should be compatible with wider wheels if necessary.

Finally, we discussed speed. The consensus was that we want to be able to drive fast. However, no decision was made on exact robot gear ratios or speed. Both will be discussed and finalized tomorrow.

Manufacturing

As soon as it was finalized that we would be building a wheeled robot, manufacturing began on the bearing blocks to support the wheels. All of the stock for the bearing blocks was cut and the first operation began on the outside bearing blocks. We expect to complete the first operations on all of the bearing blocks tomorrow.

FRC Kickoff Meeting Review

The 2011 FIRST Robotics Game Has been Announced: Logomotion

Team 254 met at Bellarmine in the morning to discuss the game.

Here are the notes from the FRC Kickoff Meeting.

Robot Attributes for Successful Gameplay:

- Minibot

- Score on Top/Middle/Low Pegs

- Blocking

- Uber Rings

- Traverse Field Quickly

- Logo

- Rearrange Tubes

- Pickup from Floor

- Rings from Human Player

- Follow Lines

Obstacles to Successful Gameplay:

- Broken Partner

- Minibot Fall

- Opponents Block (Goals and Pickup Stations)

- Popped Tubes

- Wrong Logo

- Partners in Way

- Bad Visibility

Methods of Scoring and Defense:

- Minibot *

- Scoring Tubes Everywhere *

- Ubertube *

- Blocking

- Wall

- Fast/Maneuverable *

- Pick from Ground *

- Pick from Human Player

* means that the method was determined to be Essential.

The Day Before Kickoff

It’s the night before kickoff and what a productive day it’s been.

The day started out with us ordering over 250lbs of Aluminum from Coast Aluminum in Hayward. The metal will be used to construct the robots for Team 254 and Team 1868. Although we don’t yet know the game and don’t know what the robots will look at, we are predicting that they will have metal frames, so we bought the material to build frames. After it was ordered, EJ and Sunshine drove up to Hayward in a NASA truck to pick up the material.

At the lab, other team members worked to put together a final list of consumable lab supplies that NASA will purchase. Most of the items on the list were ordered today and the remainder will be ordered over the weekend.

Also at NASA, several programmers from both the simulator group and the robot group were working on various tasks in preparation for the busy robot build period.

Finally, several students worked hard to put the finishing touches on the NASA lab to prepare it for build. The couches were cleaned and brought back upstairs and the welding table was polished to remove rust. The field was vacuumed and shelves were organized.

9 Hours Till Kickoff

Go Poofs!

T-Shirts Ordered

The team T-Shirts are ordered and should be ready just in time for the Bellarmine VEX Tournament.

Cleaning up the Lab

Today at the NASA lab, several students and mentors were working together to clean up the workspace and prepare for the build season.

The computer workstations upstairs were put together after the painting. All of the wires were nicely ziptied and the process of software updates began. In the next few days, we need to update all of the computers with current versions of SolidWorks and other crucial software. Furthermore, we need to build a wired network at the lab so that we can share printers between the computers. On the white boards, vinyl stickers were cut to label each teams’ white board.

Downstairs, Devastator was prepared to be removed from the NASA lab for semi-permanent storage at Bellarmine so that it can be used for team outreach events and demonstrations. This freed up space under the south stairwell so that we were able to move the vertical bandsaw into its own cavity, improving the safety of the workspace. We also spread out the sanding and grinding area and moved a wall-mounted shop vac out of the sheet metal area into the sanding and grinding area so dust and debris can be vaccumed up.

In the sheet metal and welding corner of the lab, work continued to prepare the area. We re-arranged the extremely heavy equipment, putting the welder in a position so that its cord could reach the outlet and so that it is easily accessible. To accommodate these changes, we had to slightly adjust the positioning of the sheet metal shear and break and move the large arbor press into the machine shop.

In the general work area, we continued cleaning and organization and also began resurfacing the workbenches so that they have nice, smooth surfaces to work on.

Everything is coming along great and we are very excited for the Saturday FRC kickoff.

Floor Painting Complete

Today the mezzanine floor was completely dry which allowed the tables and chairs to be moved back upstairs. A few students were present and helped set up the computers and get things ready for the upcoming FRC build season. The office supplies and mentors cabinets were also sorted, leaving only a few tasks left to be completed tomorrow and Thursday.

254D High Hangs!

VEX Team 254D has been working hard since their last tournament to improve on their design as much as possible. After a lot of work, their robot successfully high hangs on the ladder for a whopping 20 points!

All of the Team 254 VEX Teams are busy pulling together their robots before their Thursday deadline.

Lab Floor Painting & Cleaning

Today, more team members met at the NASA lab to apply a second coat of paint to the floor on the upstairs mezzanine. The newly painted surface looks great and we will move the furniture upstairs tomorrow once the paint dries. Furthermore, we mopped and vacuumed the floor downstairs and organized the tool chest, the white shelves and the cabinet in the machine shop.

Lab Floor Painting

Today, several team members met at the NASA lab to paint the floor of the upstairs mezzanine. Two weeks ago, we sanded the floor to remove the chipping paint and last week new paint was able to be purchased. To prevent chipping, we are using a urethane-based industrial paint. Tomorrow, we will meet again to apply a second coat of paint.

Scouting/Spirit 12/6 and 12/13

Hey team,

First, I apologize that last weeks update didn’t get put up. I wrote it, but for some reason it didn’t post…

So, last weekend (12/4 specifically), teams 254A, B, and D competed in the Pan Pacific tournament, and 254C, E, H, and S competed in Fairfield. 254A and B took home their championship, and thanks to some great scouting 254E and H dominated at Fairfield. CheesyScout was used at Fairfield, and appeared to mostly work.

On the spirit side from last week, James Garbanati has agreed to lead a refurbishing of the mascot costume. Major grievances to be fixed are the amount of air flow in the costume, and the washability of the costume. The plan is to put more ventilation in the head, and to make it possible to wash the sweat out of it, instead of just febreezing the hell out of it after each tournament. If you are interested in helping James, email him at [email protected]

For today’s meeting, the results of this Saturday’s San Ramon tournament were announced. 254D and H competed. Although both were experiencing field-related difficulties, H ended up ranking, and both D and H were picked in the first round. Unfortunately, they were picked by different alliances, and so were pitted against each other in the quarterfinals, where H prevailed and went on to win the whole tournament. However, D went straight to the driver’s challenge field after their defeat, and scored a 72, winning the challenge by 17 points and qualifying them for the championship as well. This brings our total VEX teams that have qualified to 5, being A, B, D, E, and H.

For spirit, it has been decided that we will be creating a new flag, replacing the one that was lost last season at the championships, which was replacing the one that was lost two seasons before that at the championships, which was probably replacing a flag lost way before any of those, most likely at a championship. It was immediately agreed upon that we would not lose this one, at a championship or otherwise. It was debated whether or not to make 2 flags, one with the FRC swoosh and one with the Vex swoosh, and it was agreed to wait until it had been decided whether the Vex swoosh violated copyright or government logo standards on whether or not to make two flags. If you are interested in helping me create this flag, email me at [email protected]

That’s about it. Go Poofs,

Erik

San Ramon Tournament Results

On December 11th, 254D and 254H traveled to San Ramon to represent Bellarmine at its fifth tournament of the season. After technical difficulties with the field and limited time, the teams played 3 qualification matches leaving 254D with a 1-2 record and 254H with a 2-1 record. The 6th seeded alliance went on to pick 254D and lost in the quarterfinals to a dominant alliance carrying 254H. The third seeded team, 3129A, picked 254H and 4804A and ended up winning the tournament. However, the winning did not stop there. 254D, after being knocked out of eliminations, was determined to win Robot Skills and scored 72 points. The tournament and robot skills wins bring home two more qualifications for World Championships leaving the Poofs with 5 spots to Worlds for 254A, 254B, 254E, 254H, and a newly added 254D.

On another note, all vex robots needed to be done by the end of this semester. Although every robot is competition-ready, many teams are making a few repairs and fixes to their robots after being in competition in the past few weeks. In the heat of this competition, the JVN Design Challenge entry never got finished. Lack of concrete deadlines and motivation lead to the downfall of this project.

In light of increased competition for Vex, Derrick Dominic was able to contact NASA employee, Dr. Wendy Holforty in order to obtain Vex pneumatic kits for the team. Due to liability concerns and respect for Dr. Holforty’s parts, a release form must be made before any teams can borrow these parts. Some teams have already expressed interest in the kits and it will be exciting to see what they are used for.

The goal by the end of the week is to have all the Vex teams prepared for the winter break to make the changes and fixes they need to. The parts locker will be open on Monday, and probably Tuesday. The kits will be handed out near the end of the week after forms get filled out. There might also be an overall team design / team meeting for the Vex participants over break for those interested in learning and discussing more about the team’s goals coming next semester.

-Roshan

Programming Update

We had a meeting on Thursday at Bellarmine, in which we covered a lot. By this week’s meeting, we will have finalized the programming team’s organization into the two groups, and everyone will have their assignments. We have split the team into two groups, one working primarily on the simulator that Dmitriy developed, and another on the actual robot. This Friday, most of the programming team met at the lab to work on the robot, which was a pretty successful meeting. We were able to play around and experiment with the various capabilities of the robot, and we were able to create and execute a simple autonomous program. We have 5 people who are interested in being full-time programmers, which is a good number for the programming team.

Archiving Update

For this week, no meeting was held. At the large team meeting I personally contacted everyone who has not turned in their assignment. In addition, I gave them the names again so that they can go back and check. Finally, someone on the archiving team agreed to take the large list that we have to search for any deficiencies so that he can update them himself. This week should be a time for consolidating the lists.

FRC Build Update

Friday the 10th marked our third and final CAD Friday and our final FRC Friday of the semester. We had a great time and started to explore some of the more advanced assembly and sketch features of SolidWorks. Although it would have been nice to have more time so that we could have gone into more depth and gone over more features of SolidWorks, we had a great opportunity to give many students a broad overview of the program. Overall, I think that the FRC Friday program this semester was very successful and I hope we try something similar again in future years.

Today, we had our second Machine Tools Training of the semester with two more students getting trained on how to use the machine tools at the lab. For reference, I’ve put up a list of the students who are trained here. If you would like to sign up for machine tools training in the coming weeks, sign ups are here.

As the semester wraps to a close, we have very little time left to get everything ready for the FRC season. We have scheduled Open Lab time for December 20-23. Please sign up for this time here and come in if you are interested in working on Programming, CAD or just helping get the lab ready for build. There are no space limitations but if nobody signs up, we will likely cancel the session and the lab won’t be open :( There are still numerous items on the lab to-do list that need to get done and we need as much help as we can get. Let me know if you have any questions for this.

Remember, students interested in CAD and programming: Coming to the workshops alone is not enough to become a CAD or Programming master. To gain all the skills neccesary for the robot work, you will have to put in some extra time outside of the workshops. Coming to the open lab days (mentioned above) is an excellent opportunity to get the much-needed experience with CAD or Programming.

26 Days Until The 2011 FRC Season Begins!

Happy Holidays and Go Poofs!

Nick Eyre

VEX animation started

The animation team began making a game for this year’s vex animation challenge.

The rules of the animation challenge are: http://forum.robotevents.com/design/challenge/detail/94

Here are the rules to our game:

http://team254.com/images/stories/the%20field.png

There are small tops upside down on the field in 4 circles of 6 with a large top in the middle of each circle. There are 4 more large tops on posts on walls. There are two goals in the corners of the field on the floor. There are 4 cylindrical goals, 2 for each team, that small tops can be placed in for bonus points.

The tops can be scored in the corner goals for points by rolling them in. There is a large covering over the corner goals to prevent scoring from above. To discourage descoring, there is a small ramp, 1″ high and 4″ long that will keep the tops inside the corner goal. However, descoring is completely legal.

The small tops can also be lifted and scored in cylindrical goals for additional points.

There is a bonus piece as well. A 5 lb weight is placed in the center of the field and can be lifted onto the corner goal for a point bouns within the last 30 seconds of the match.

Dimentions of pieces:

\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\

small tops: 4″

big tops: 6″

dumbell: We’ll make it 5 lbs.

cylindrical goal: 4″ wide 12″ tall

Scoring:

\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\\

small top in a corner goal. 2pts

big top in a corner goal. 5pts

small top in a cylindrical goal. TBD

dumbell on a floor goal. TBD

Pan Pacific and Fairfield

This past weekend, the Bellarmine Robotics Team 254 once again stretched itself to the limit, entering two separate tournaments 3,000 miles apart. At Fairfield, CA, 4 Bellarmine VEX Robotics teams competed in the 2nd annual Vanden High VEX Regional, waking up early for a 2 hour drive on Saturday morning. That afternoon, after several qualification matches which pinned Bellarmine teams against those of other schools in the Bay Area, the Cheesy Poofs came out as first seed, picking a second Cheesy Poof team in the alliance that eventually won the tournament, undefeated. Across the Pacific Ocean, three more 254 teams competed at the second largest VEX Robotics tournament in the world in Hawaii, the Pan Pacific VEX Championship, second only to the World Championship. After a tough set of qualifications and 36 hours of continuous repairs on their robots, one of the the Cheesy Poof teams managed to seed third in their division. Just like at Fairfield, this team selected another Bellarmine team along with team 2438B from Hawaii and fought through two divisions and 112 teams from around the world to win the championship. After this successful weekend, Bellarmine successfully defended its winning titles at both tournaments for the second year in a row.

Archiving Update

Last week a meeting was scheduled for Thursday, but not enough people showed up, so it didn’t happen.

I have personally contacted everyone on the team to remind them of their assignments and the meetings.