Blog - February 2014

Day 36: Practice Robot and Release Video

By Luke Gardner

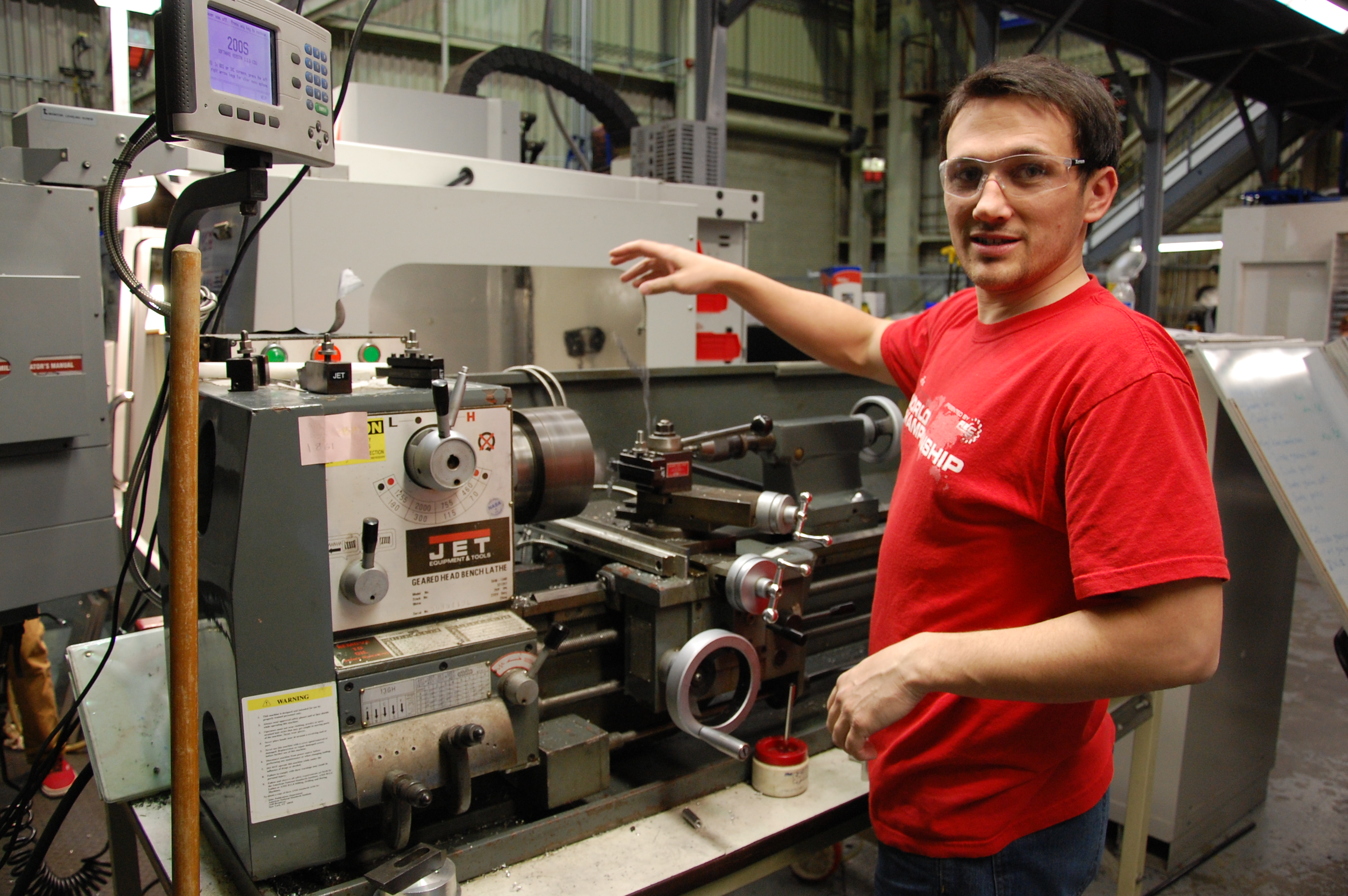

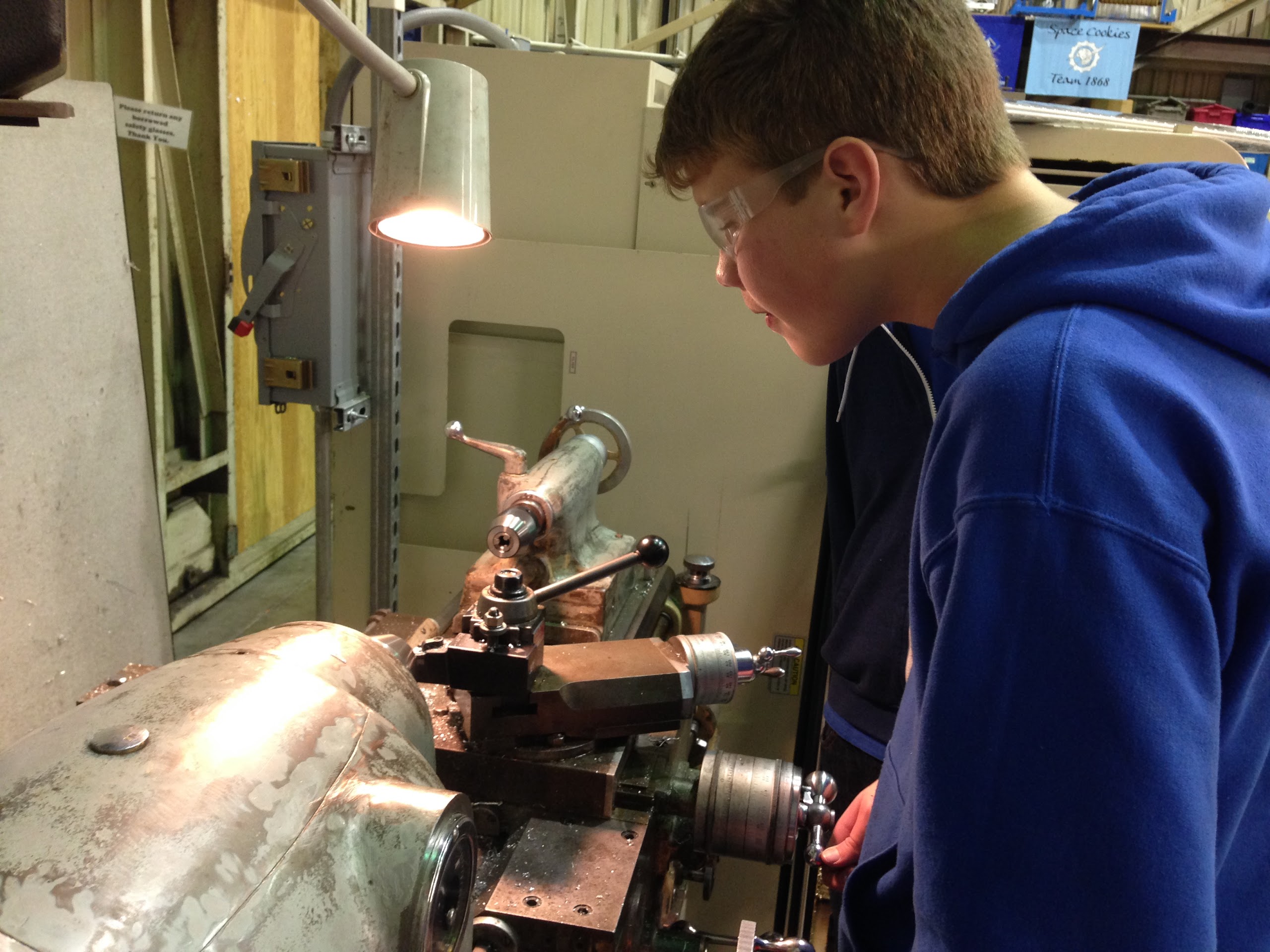

Machining

Students machined wood for the bumper and the pool noodles arrived. Parts for the control board were machined for later construction.

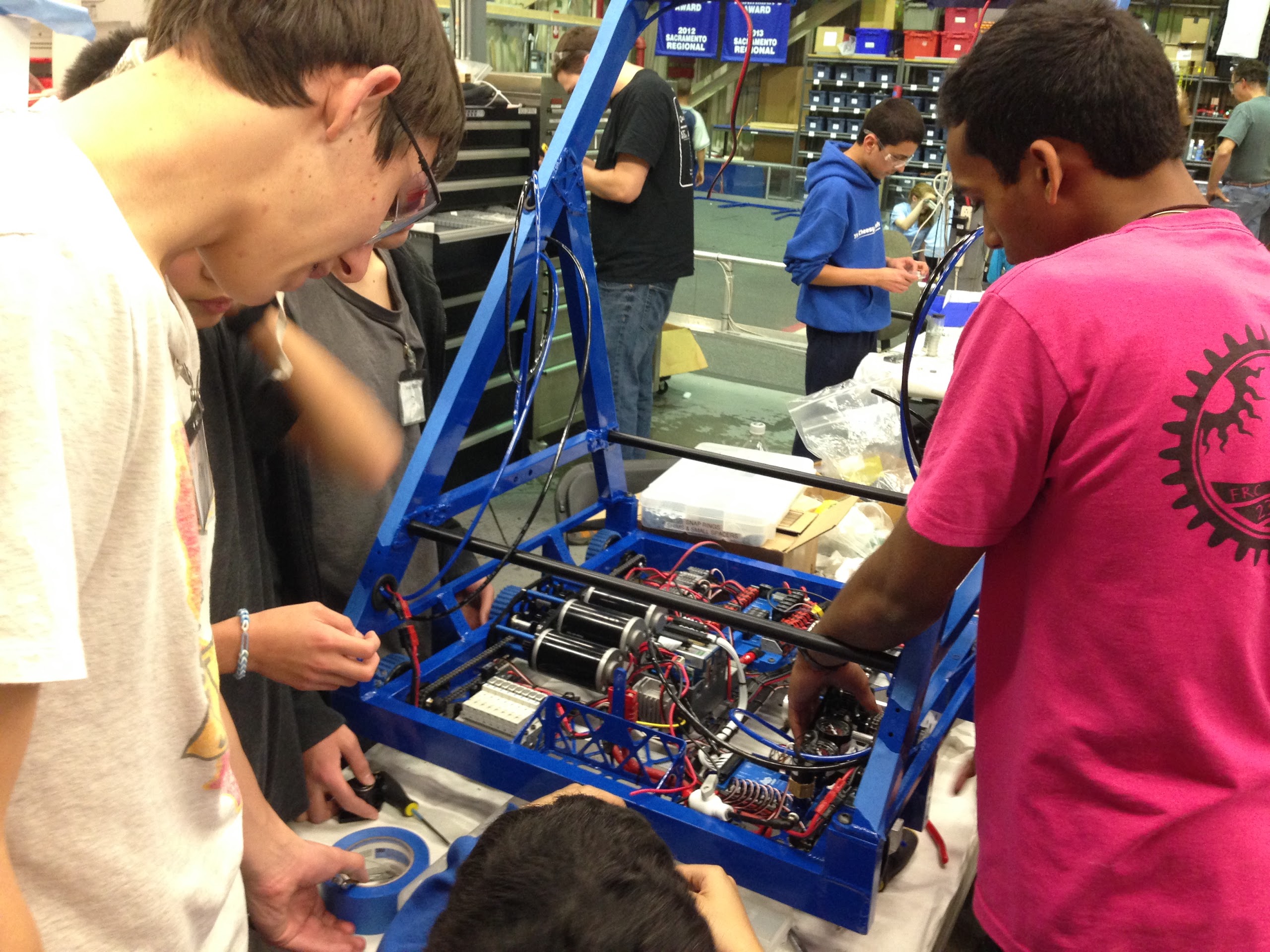

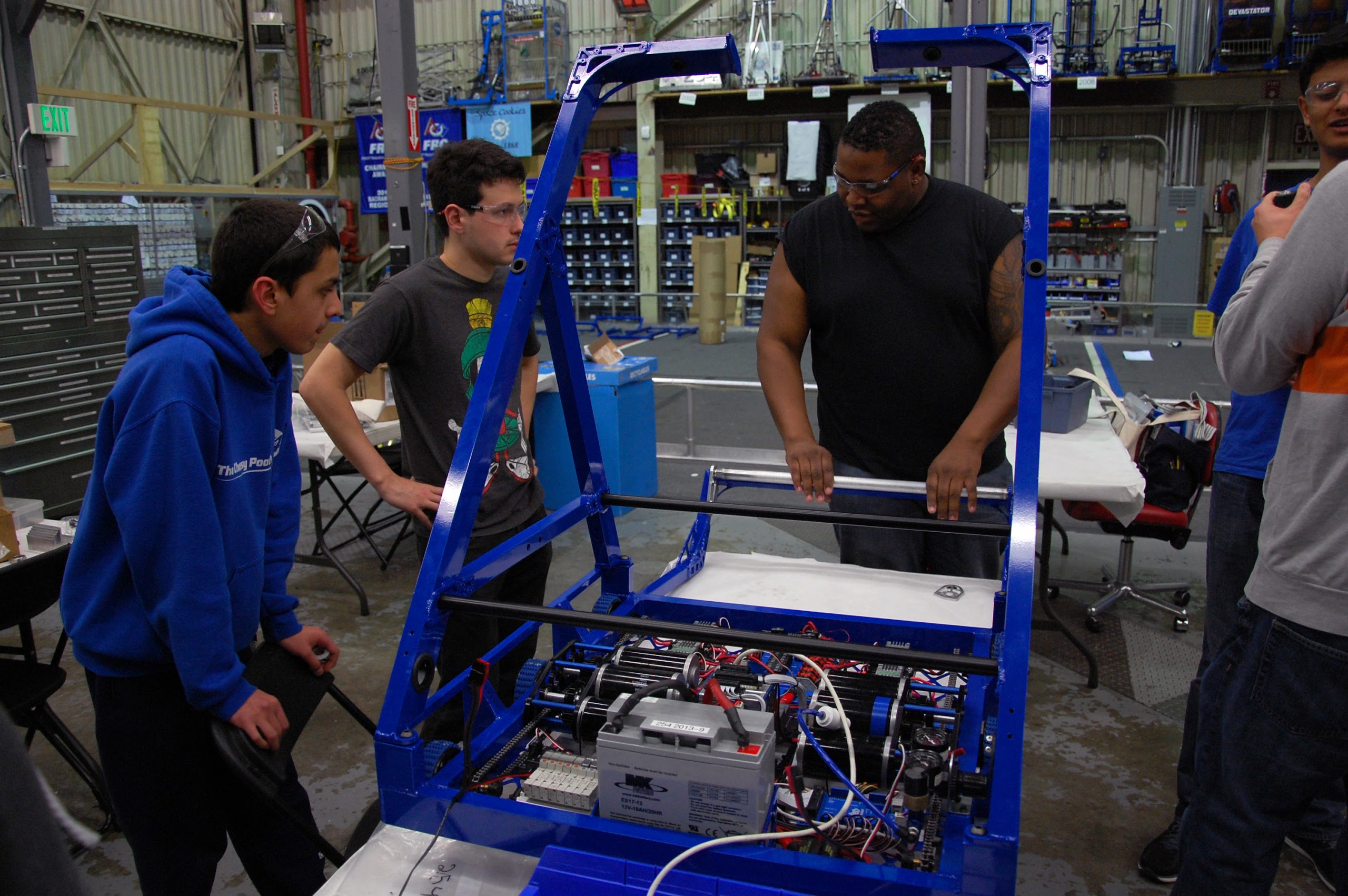

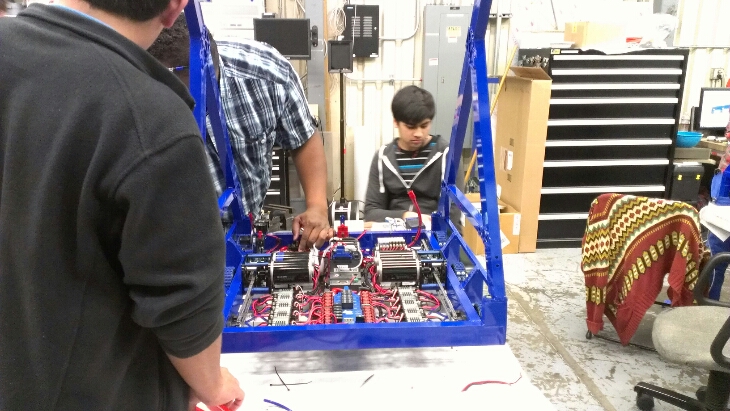

Robot Construction

Work on the practice robot continued including more wiring and work on the gearboxes. The pneumatics for the pinniped were built and attached to the robot. The gearbox for the intake was attached. Work on the bumpers began late in the night.

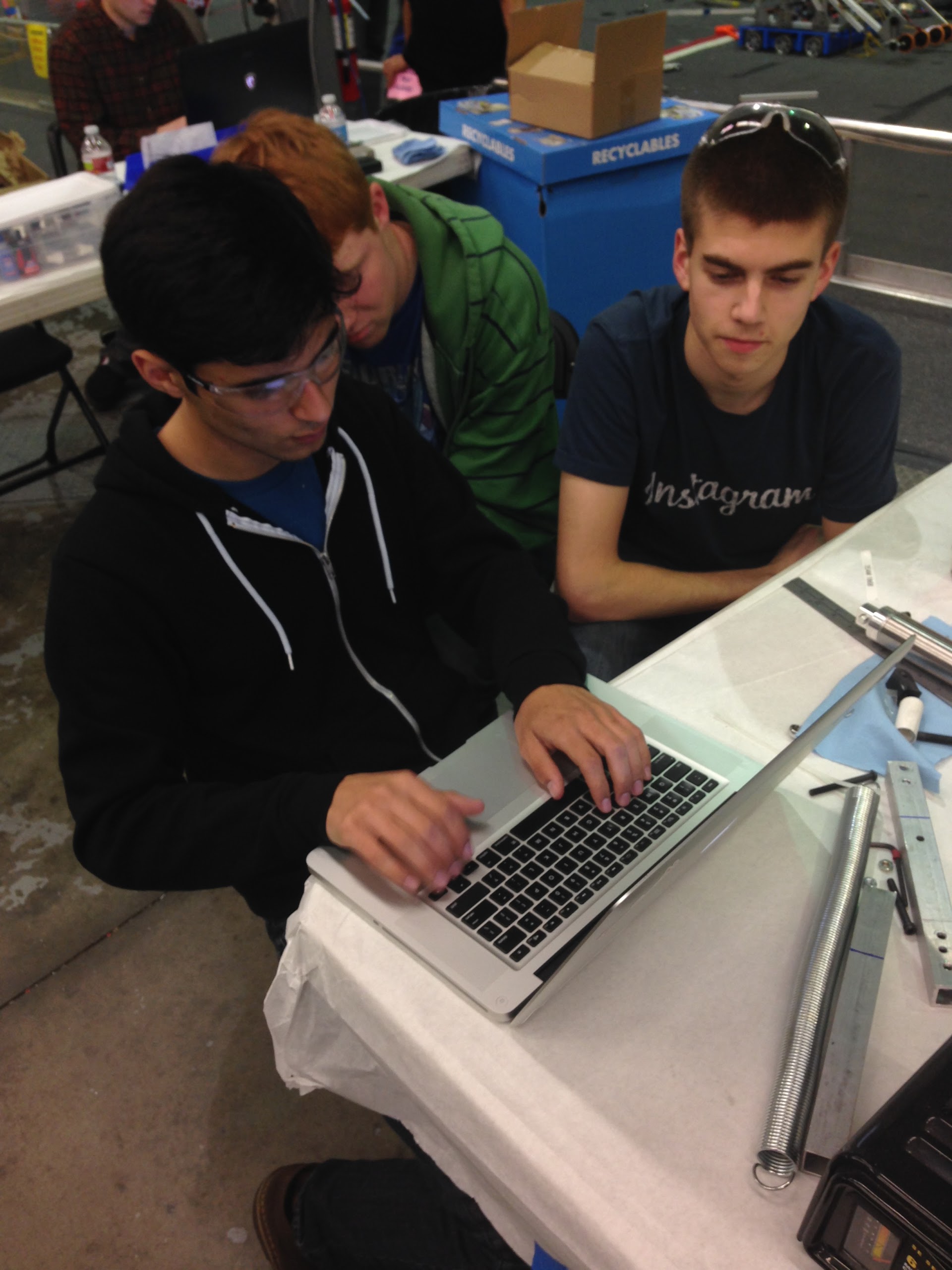

Programming

Our programmers worked on a team hours app, and others also researched and brainstormed the LEDs for the pit in Waterloo.

Later in the night the programmers worked on the mechanisms within the robot code.

Release Video

Students brainstormed and started writing the script for the release video, as well as collecting pictures and videos to be used.

Miscellaneous

More catchy slogans were thought up to be put on the Canada T\-shirts such as “Get ready to Waterlose” and “We came for the bacon and stayed for the robots.” The outside wood was organized according to size and dimension. The shed is mostly organized now and should not have to be disturbed until packing.

Action Items

- Assemble robot with Mani and Abhi

- Build Bumpers (cut pockets into wood and finish marking up Cordura)

- Programming with Kevin and Brandon

- Check trello

Day 35: Wiring and Writing

by Eliot Smullen ’16

Graphic Design

Several students continued to brainstorm a Waterloo-specific T-shirt. Some of them began considering the issue of whether the back should be left blank if the design on the front were of sufficient size and graphic complexity. The rest brainstormed catchy slogans such as “From C(ali) to shining C(anada).”

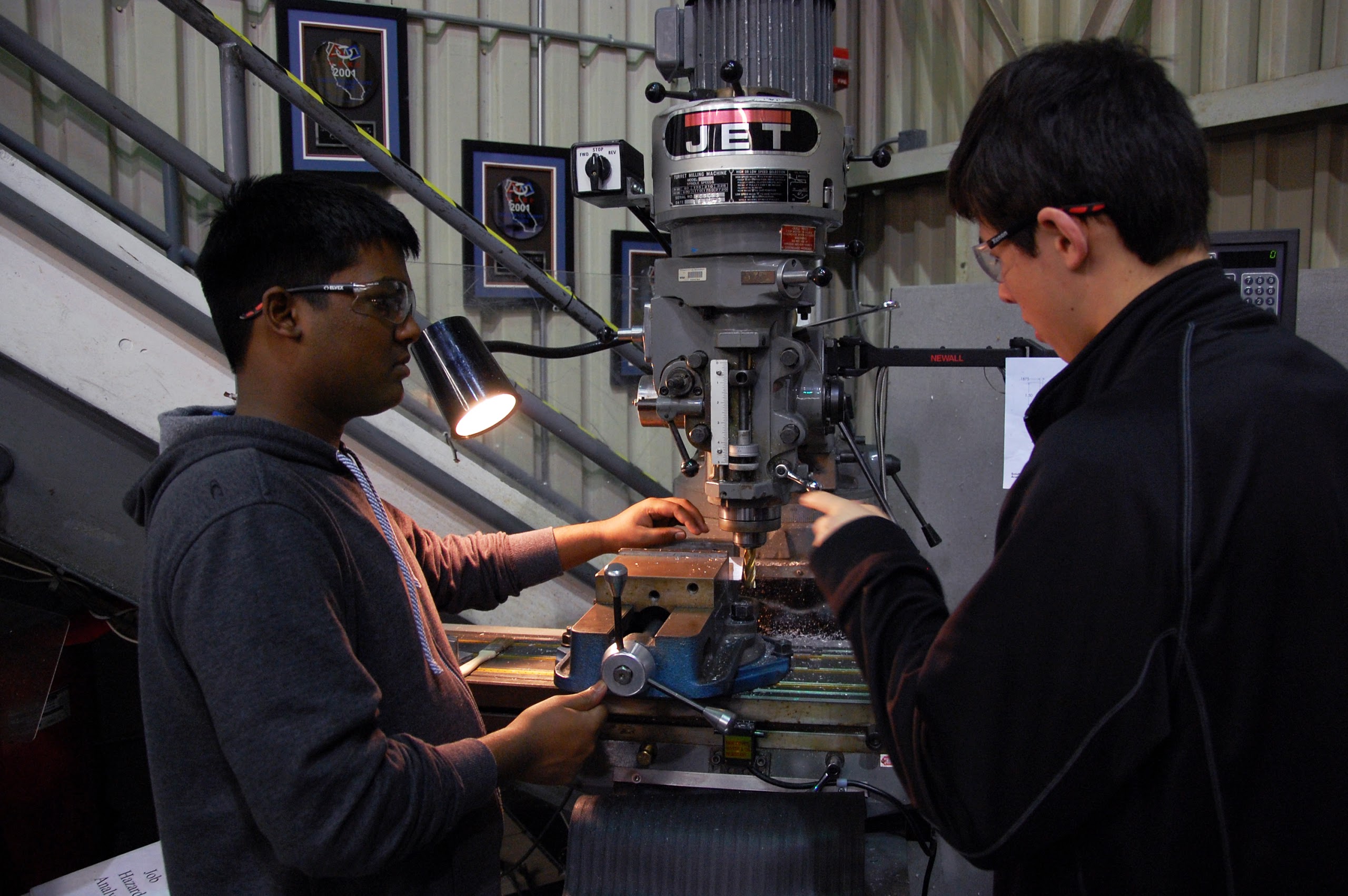

Machining

Today’s machining consisted of creating pulleys for both the intake and the shooter. Also, students begun machining parts for the bumper. The team plans to work on flywheel for the shooter.

Robot Construction

Today, students and mentors worked on constructing the intake for the practice robot. The competition bot has its intake installed and its pressure gauge wired. The practice bot will soon follow.

Award Submissions

Today, students worked on our chairman’s submission. However, they still need to edit and add evidence to the essay portion of the submission. In addition, some students began work on the Entrepreneurship Award Submission by matching up sections from the Business Plan written in the first semester with sections and prompts in the Entrepreneurship Award criteria.

Action Items

- Assemble robot with Mani and Abhi

- Wire sensors with Mani and Tom

- Programming with Kevin and Brandon

- Make bumpers

- Check trello

Day 34: Scouting and Superstructures

by Eric Wang ’17

Machining

Today, students manufactured internal shaft\-like connectors for the superstructure. These were designed to give durability to the superstructure when under stress. Also, students machined gussets for the bumper.

Scouting

The scouting team began brainstorming a new method of ranking teams since the traditional method of OPR would not be effective this year. This is still in progress.

Lab Maintenance

The driver station windows were replaced with brand new polycarbonate windows. These were then meticulously cleaned.

Robot Construction

Students and mentors mostly focused on wiring today. The regulator and the router in the drive base frame were wired, along with the wheel encoders. Also, students drilled holes through the superstructure and routed wires and pneumatic tubing for the shooter and other cylinders.

CAD

The CAD team completed part drawings for the robot bumper connectors.

Chairman’s Award Submission

The awards submissions team edited part of the entries that they created previously for the Executive Summary prompts and the major essay \(second draft\). Also, they searched for evidence in previous submissions and changed previous answers to be more direct, so that it would enhance the reading experience for judges.

Programming

The programmers busied themselves fixing bugs and issues in the current iteration of the code. This also involved uploading several versions of the code to the 2013 practice robot.

Action Items

- Work on the scouting system: see Art Kalb for details

- Edit Chairman award submission: see Jeremy Tanlimco for details

- Construct the robot with Abhi and Mani

- Debug code with Brandon

- Check the Trello

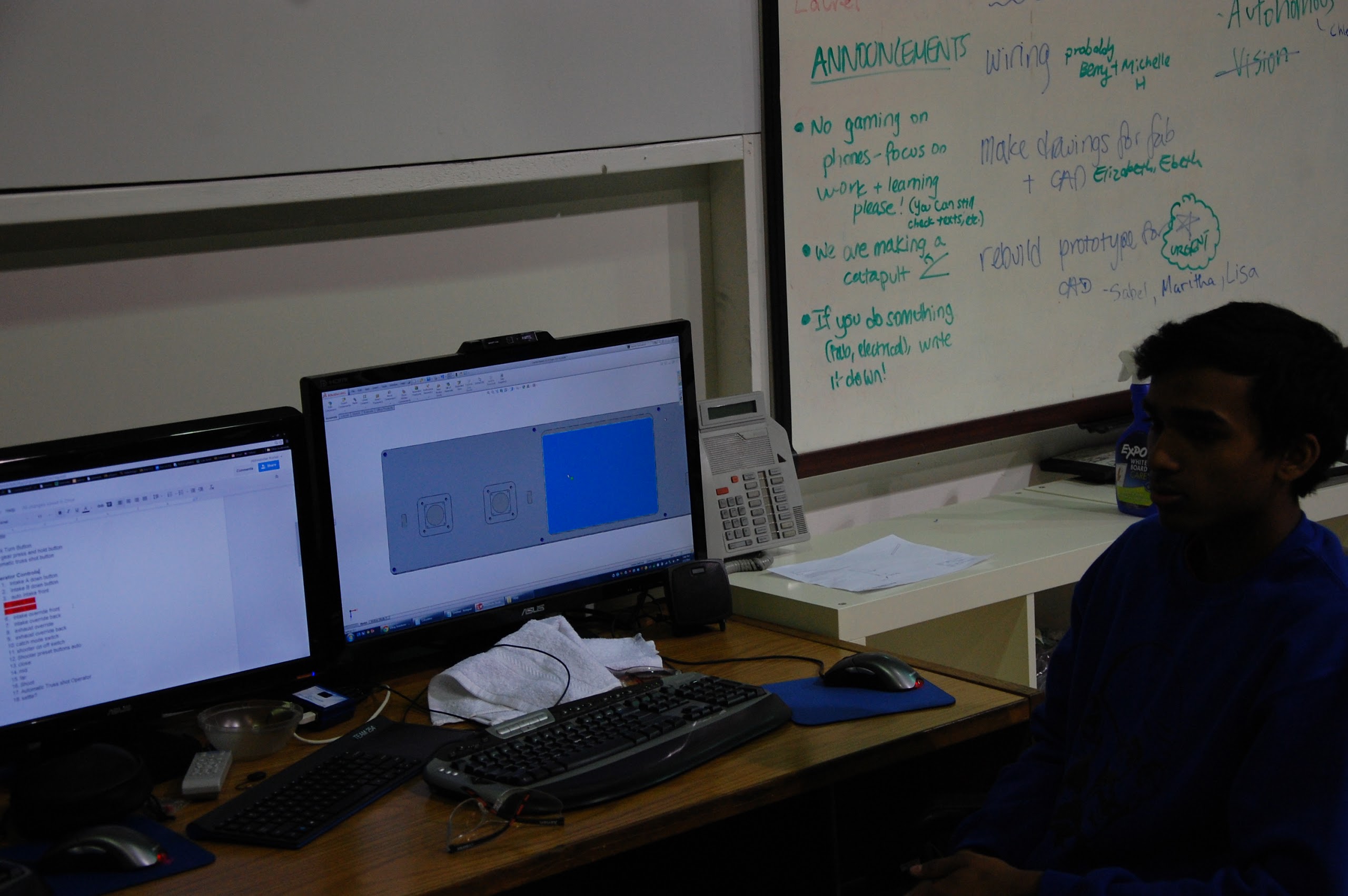

Day 33: Finishing up machining and wiring!

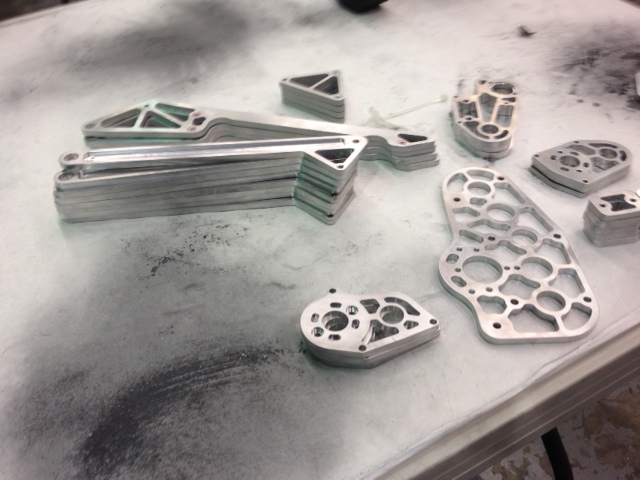

CAD and Machining

The CAD is nearly finalized and only minor details were flushed out tonight. The various gearbox plates \(intake, front intake, rear intake, shooter\) were finalized and CNCd. Today we also machined new pieces for the shooter drive shaft. Super structure,and shooter were cleaned with scotch bright. Soon a bunch of parts will sent to be powder\-coated. Once all parts are back from powder\-coating, all we have to do is assemble the robot!

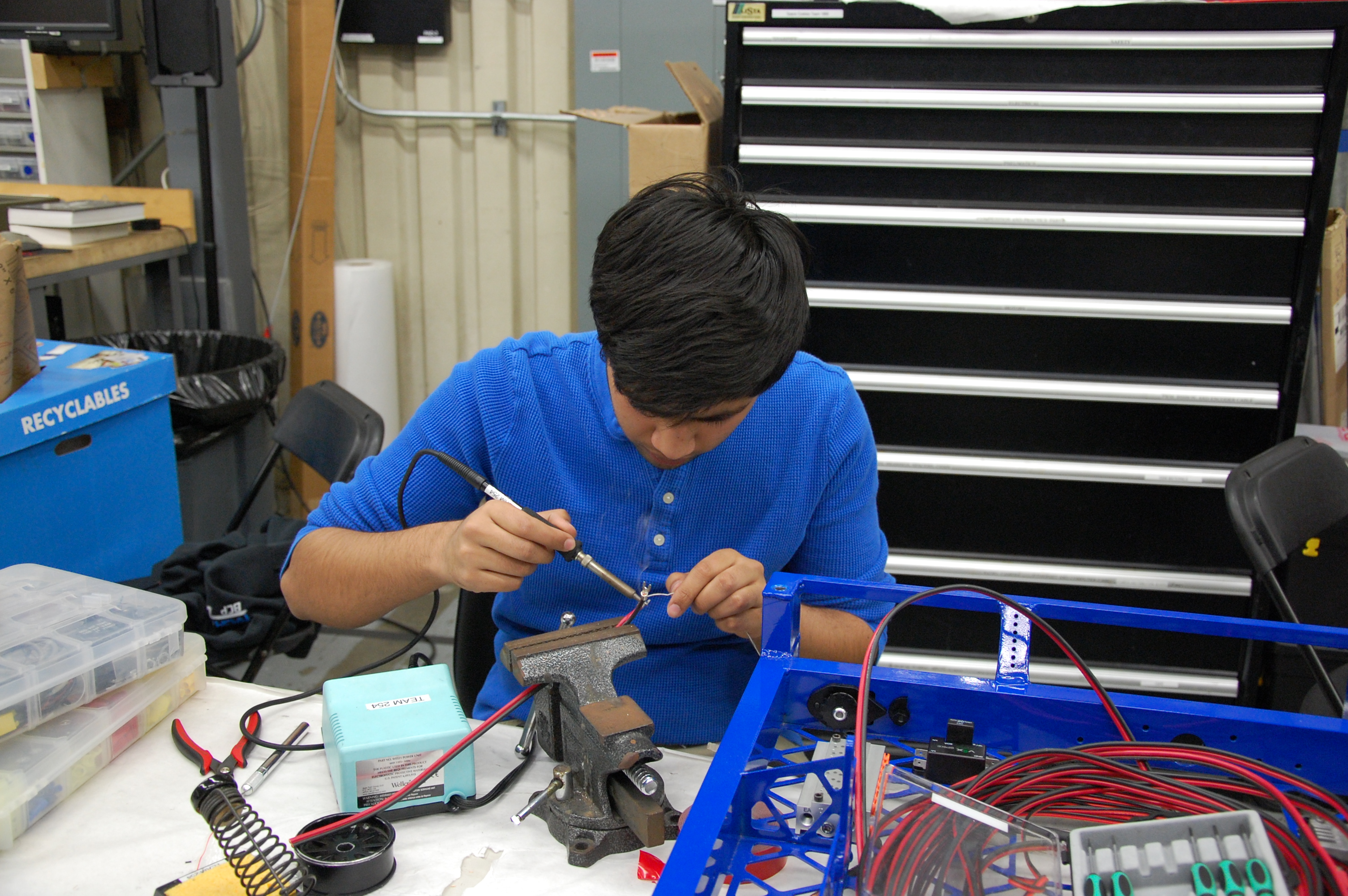

Drive Base Wiring

We finished up wiring the competition bot and are nearly finished wiring the practice bot.

Scouting

Today students and mentors began to discuss methods of scouting the game at regional events, determining objective metrics to compare robots. This will continue over time.

Prototypes

Today all the prototypes for this year’s challenge were disassembled and the parts put back in their containers. We no longer need the prototypes and they were just taking up space. However, they served their purpose.

Miscellaneous

We cleaned out and organized the Mentor and Office Supplies Cabinets to make our mentors happier.

We also now have made 2 of the plates for the cordless drill holder. More plates will be machined when we have time.

The robot cart had some extra rails attached to sides for strength. The entire cart was prepped for power\-coating.

Action Items

Finish machining parts for the shooter and front and back intakes. Send to power\-coating as soon as possible.

Finish wiring practice drive base.

Finish Chairman’s \(see Jeremy\).

Day 31 – Rest Day

Today was another rest day. Have a weld video or two as we begin week 5!

Day 30: Machining, CAD, Game Elements, and Drive Base

By Clay Rosenthal

Machining

Parts of the superstructure were made today to be welded tomorrow. Parts to hold the pieces in place while being welded were also machined. The superstructure will be welded and powder\-coated soon. The parts for the hood and rear intake were also assembled and will soon be welded and prepped for powdercoating.

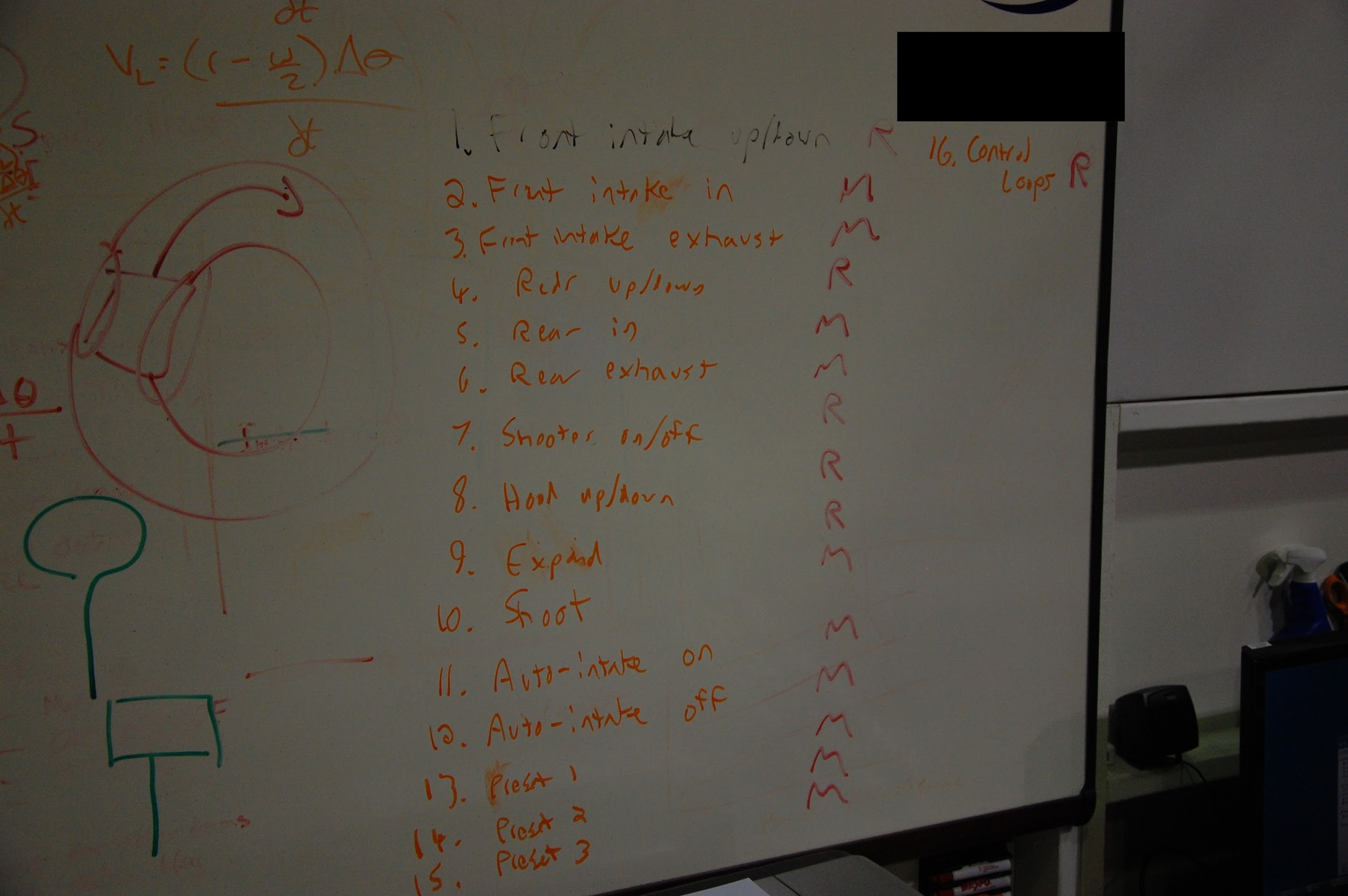

CAD

The clapper design was worked on today and is nearing completion. Locking pistons for the hood were also conceptually designed on today. A new control board with sixteen buttons is being designed. The buttons are described below \(‘R’ stands for rotational, or a switch, and ‘M’ is for momentary, or a button\).

Game Elements

The truss was worked on more today and is nearing completion. It is standing tall but still bending. The two halves from yesterday were attached together. It hasn’t been hung over the field yet and is still being completed outside.

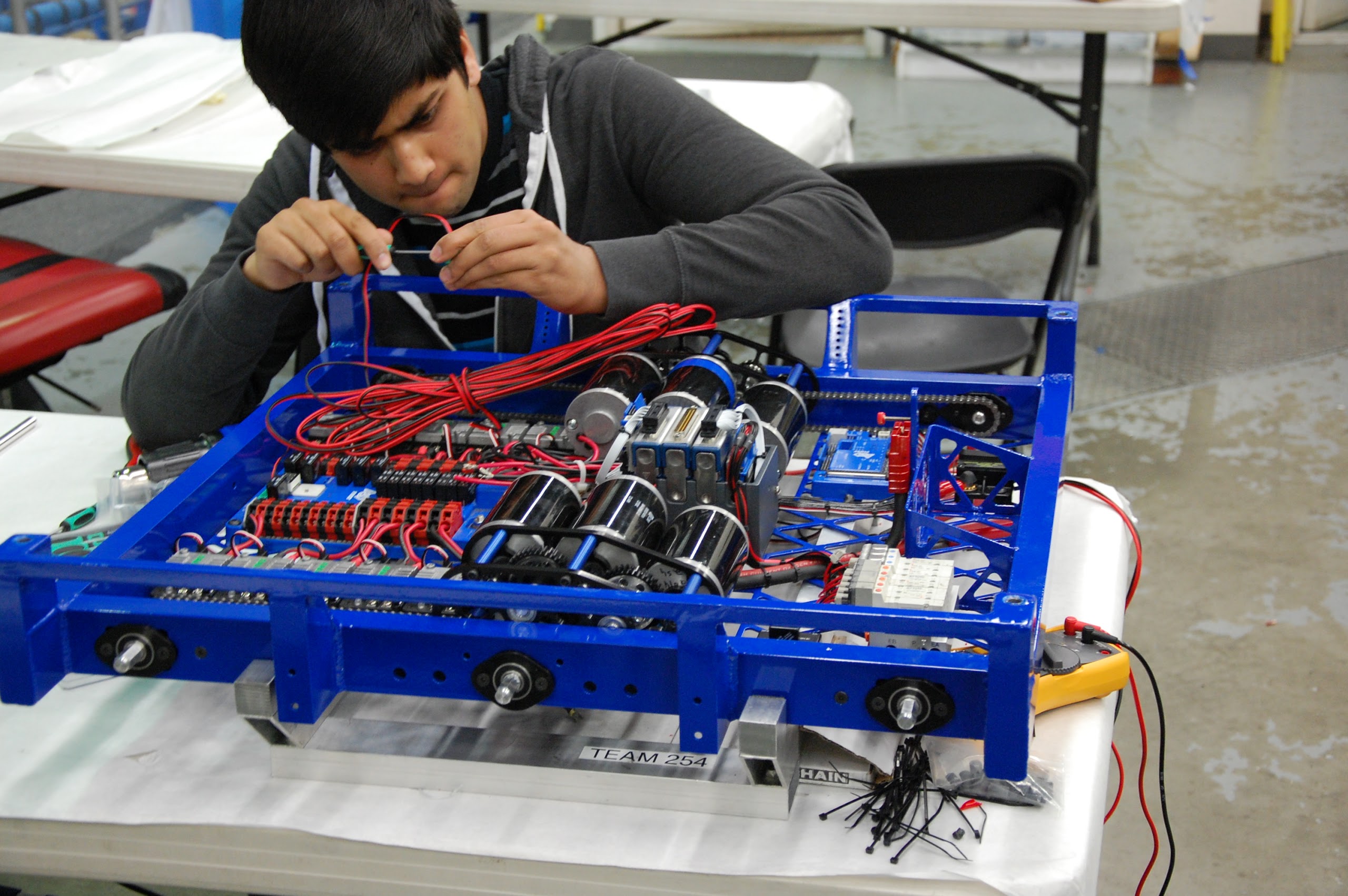

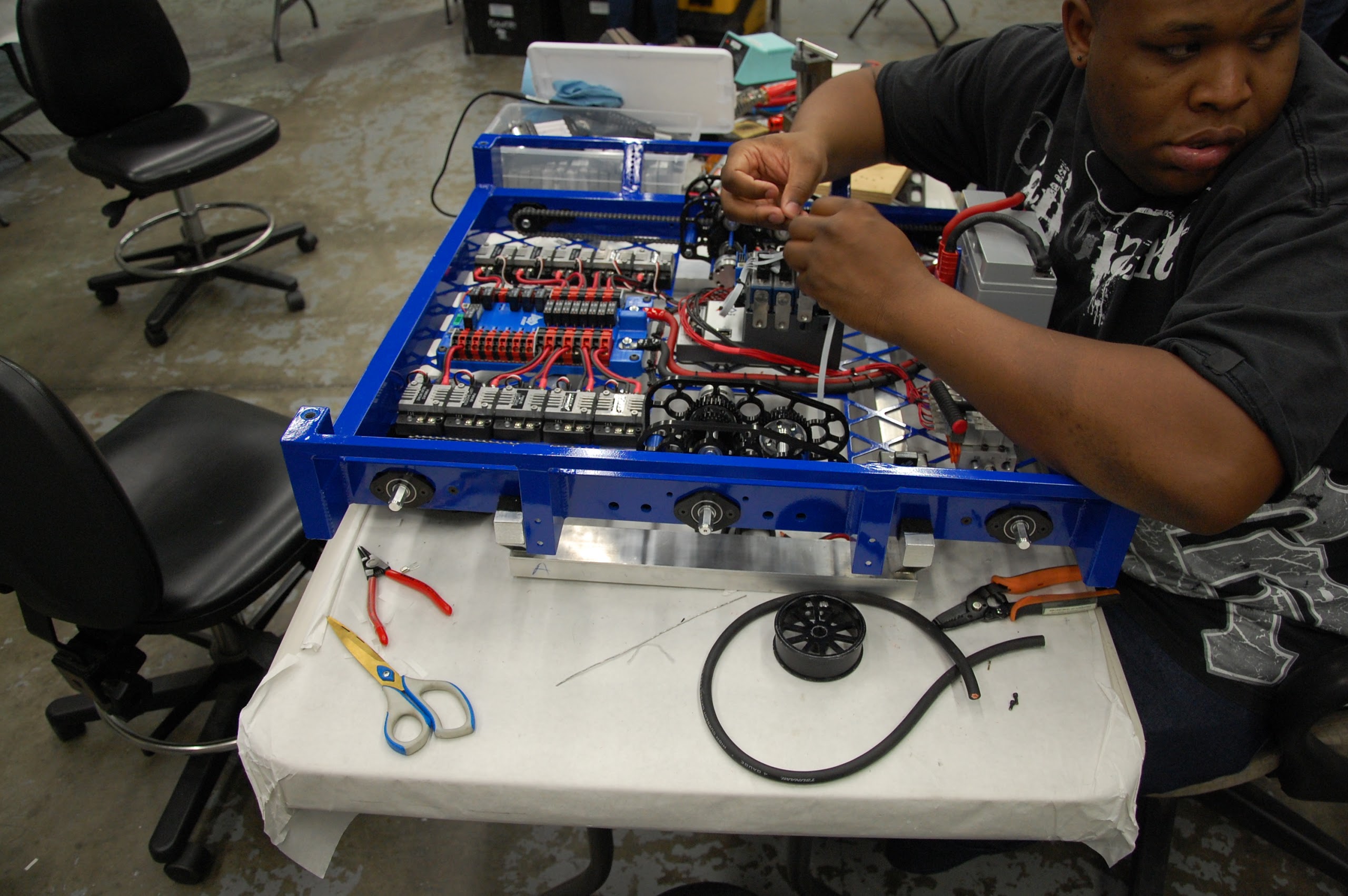

Drive Base

The competition drive base was wired and is pretty much ready for driving. The practice drive base is not far behind. The wheel axles now have chains attaching them to the gearboxes and the gearboxes on the practice drive base have CIM’s on them. New CIM’s have been ordered and will be put on when they arrive.

Action Items

- Wire andersons and drive gearboxes, Ask Mani

- Wire practice robot, Ask Mani

- Get everything ready to be welded

- Machine parts for hood, shooter, and intake gearboxes, ask Pat

- Finalize design for clapper, ask Colin

- Finish parts for shooter, hood

- Machine gearbox plates and piston mountsWire andersons and drive gearboxes. Ask Mani

- Wire practice robot. Ask Mani

- Get everything ready to be welded

- Machine parts for hood, shooter, and intake gearboxes, ask Pat

- Finalize design for clapper, ask Colin

- Finish parts for shooter, hood

- Machine intake gearbox plates and piston mounts

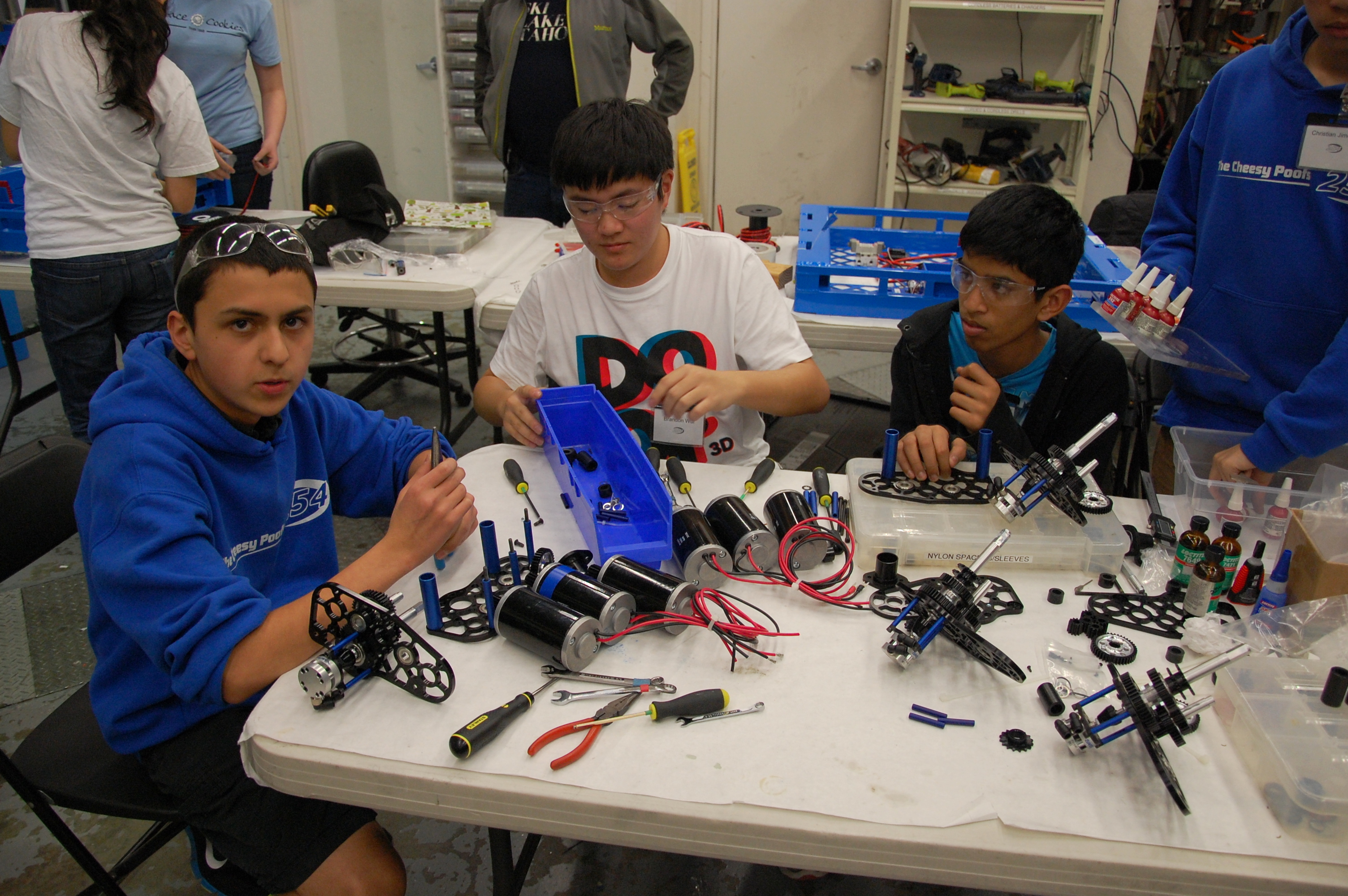

Day 29: Assembling Gearboxes

By Michael Simeon, Matthew Tran, Christian Bagamaspad, Stephen Pinkerton

Machining

Today, members manufactured shooter shafts, standoffs, spacers for gearbox, and crosspieces for “seal.” Additionally, they began detailing and manufacturing parts for the front and back intakes.

They also machined parts for the hood weldment assembly, which still need to get welded. Most of the other hood elements are still being designed.

The superstructure parts are done and ready to be welded. Part of the hood attachment still needs to be CNC’ed before sending items to the welder on Monday.

Gearboxes

Members also assembled gearboxes, replacing long standoffs with shorter ones. There were some issues after assembling them the first time where bearings didn’t fit properly. These issues were mostly resolved after assembling them again, but more carefully. There may be more issues with spacers that we need to investigate tomorrow. All in all, only 2 of the 6 gearboxes have been assembled \(the ones for the competition bot\).

Wiring

We started wiring late into the night and are being careful to do it accurately. The goal is to have this done very soon so we can continue driving.

CAD

After successful testing the v\-shaped popper, the team decided to go with the prototype, and are currently designing it in SolidWorks.

There was significant work done on the shooter and hood CAD. Members added more detail, as well as some shafts, spacers, and screws.

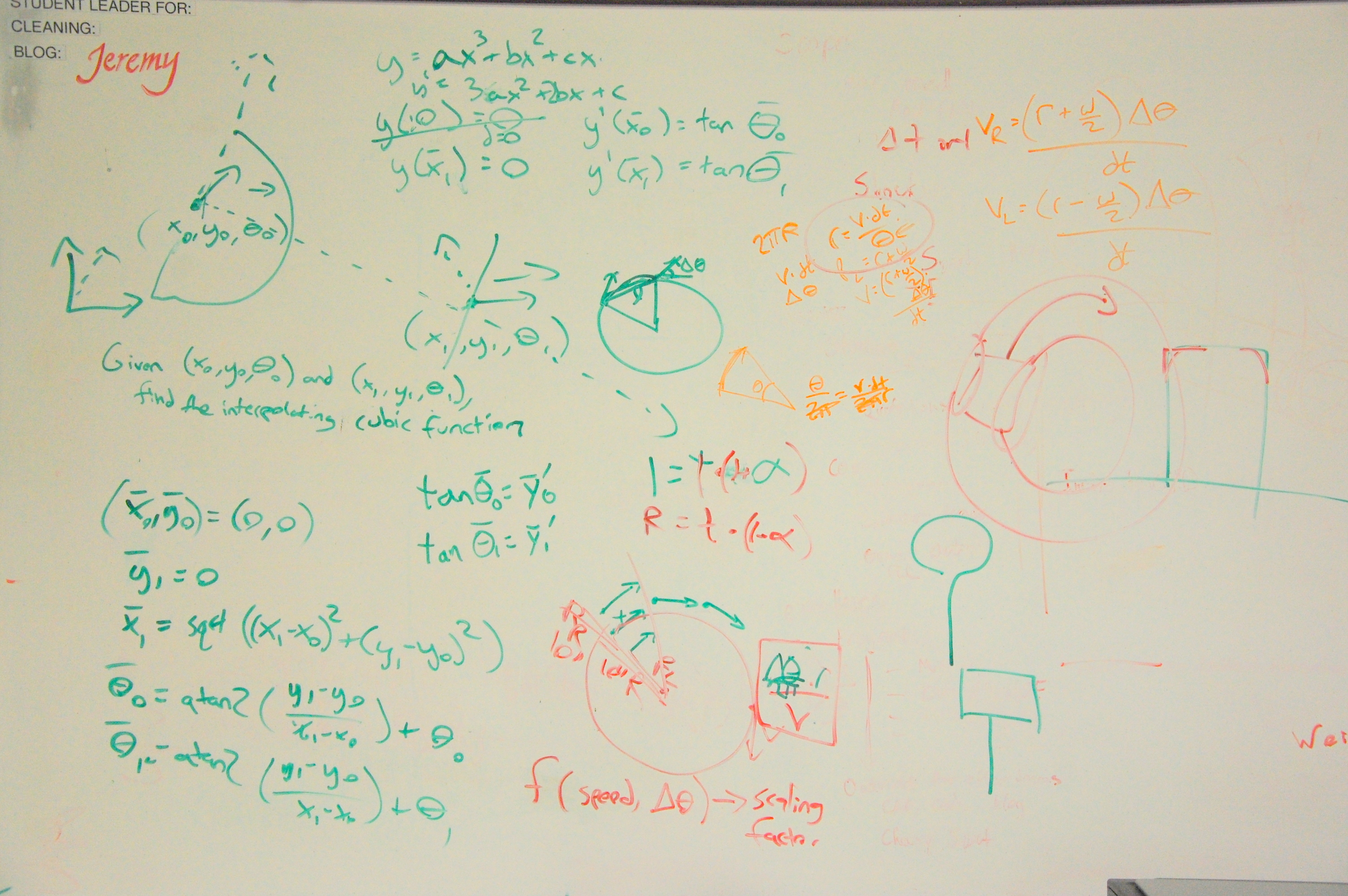

Programming

Today, the programmers worked extensively on cubic spline interpolation and trigonometric calculations. The purpose is to be able to turn smoothly and accurately. They implemented the calculations in a new Java project called TrajectoryLib, complete with unit testing. By the end of the day, they ironed out most of the bugs, and have not yet tested the code on the robot.

Moving forward, they’re looking to create a live position\-tracking page for the robot.

Graphic Design

Today, some students made progress on the official team shirt for this season by trying a new design based on the Aerial Assist logo. They also incorporated the logos of our current sponsors.

Game Elements

The team assembled a homemade truss \(instead of purchasing the official game element or buying actual trussing, which would take more than a week to ship\). Unfortunately, it is not completely sturdy and bows in the middle. It has not been hung up across the field yet.

Action Items

- Check Trello!Wiring drivebases

- Continue designing hood

- Debug and test turning code