Blog Archive

Day 40: Intake and Truss

by Matt MacDonald ’17

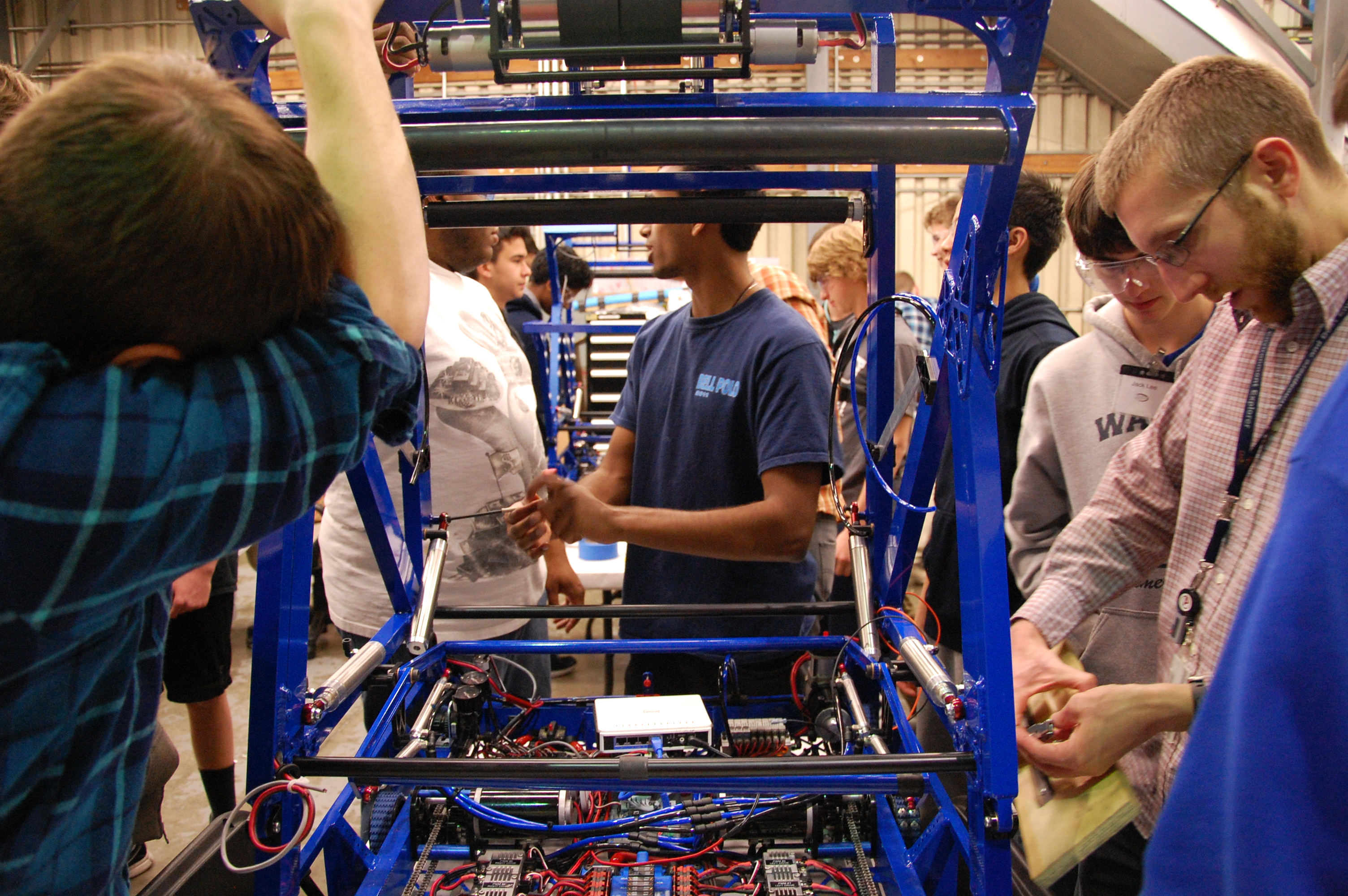

Today, our team worked to address some problems in our intake and truss. We also worked on programming an important system in our robot.

Intake

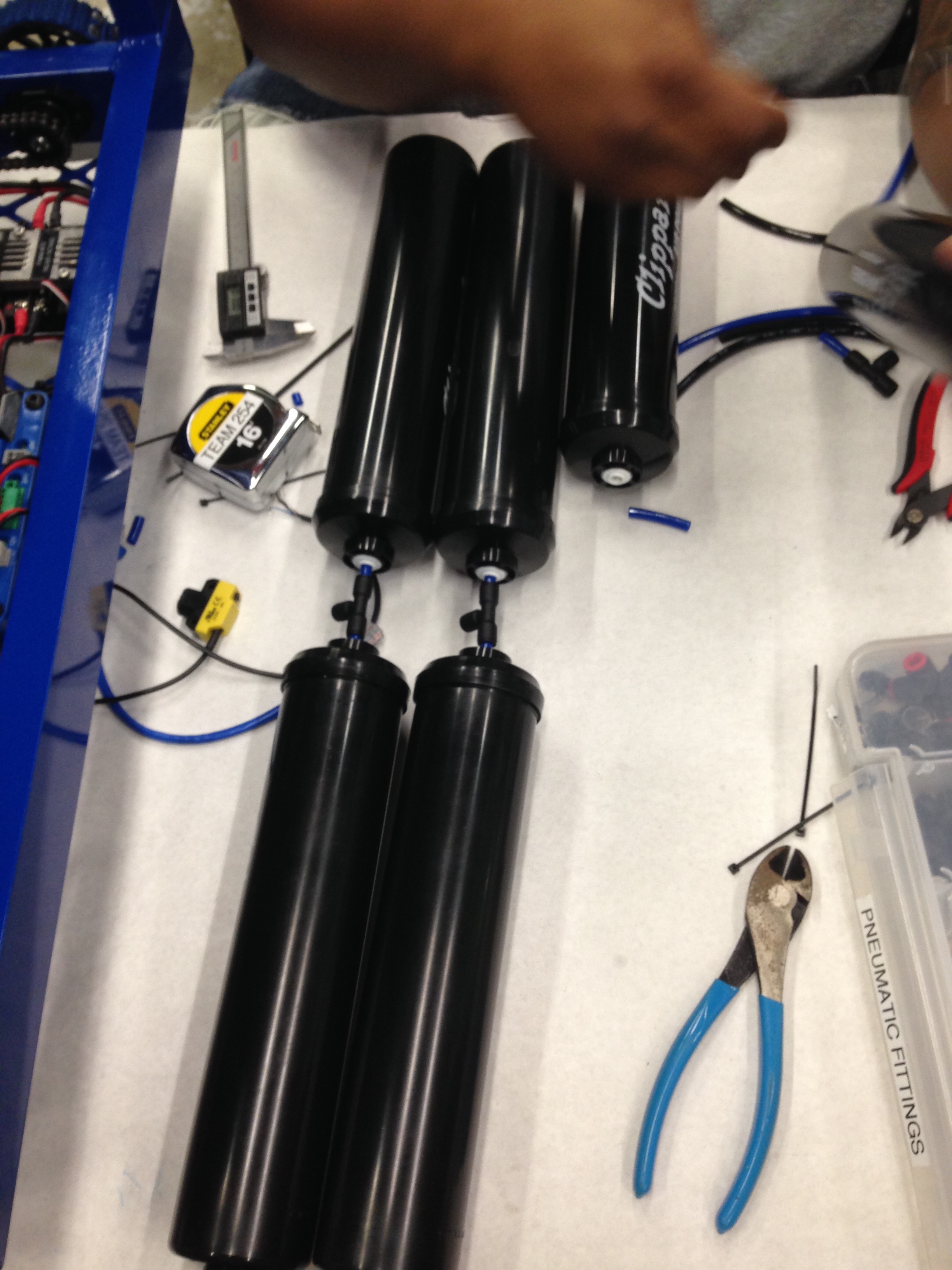

Our team worked to install and improve our intake system. First, our team changed out the bent arms in our robot and installed some gearboxes and motors. Next, we drilled grommet holes and finished up some wiring. Lastly, we used pneumatic wiring to further improve our intake system.

Some students created intake holders very important to the success of the robot.

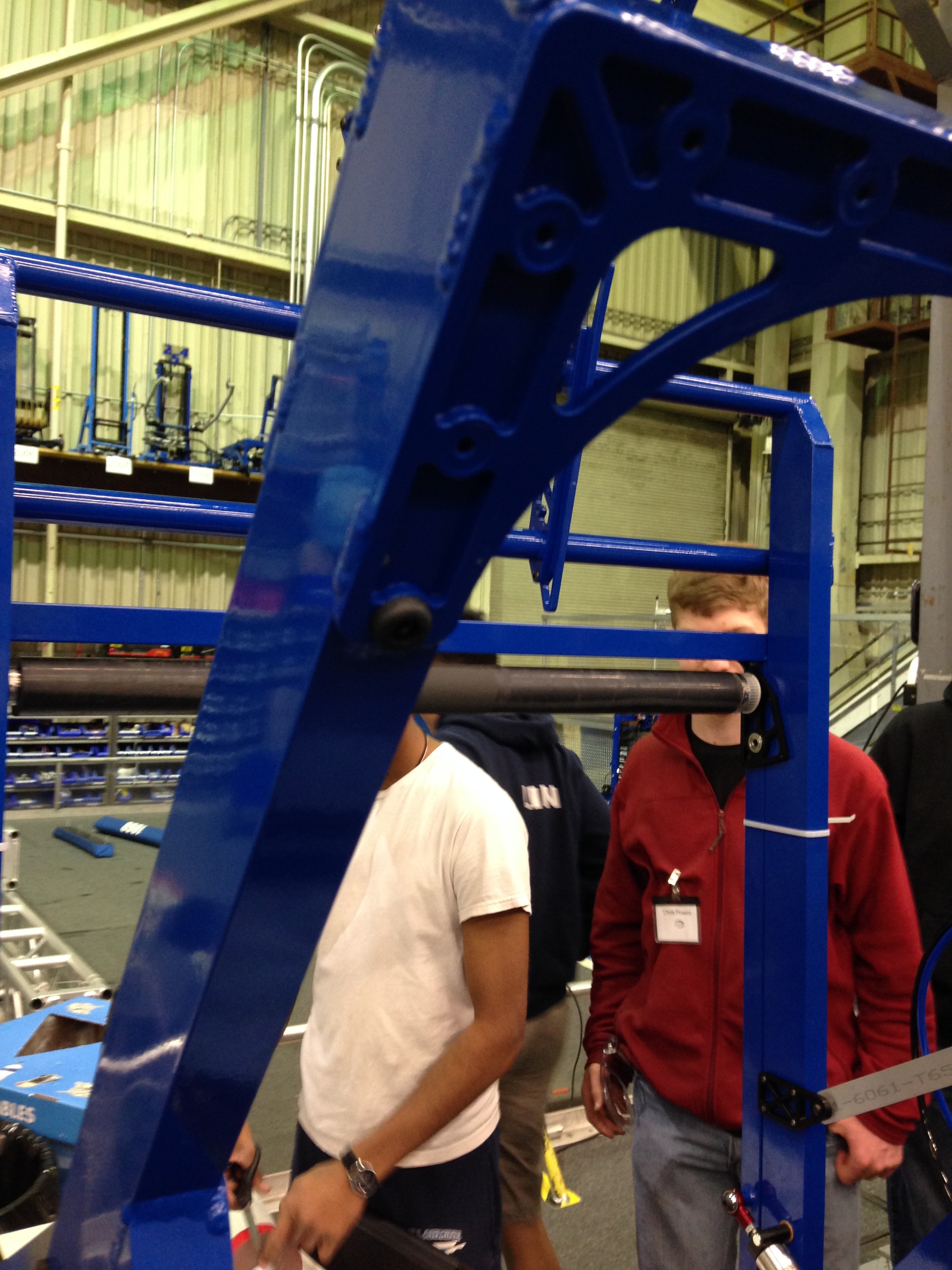

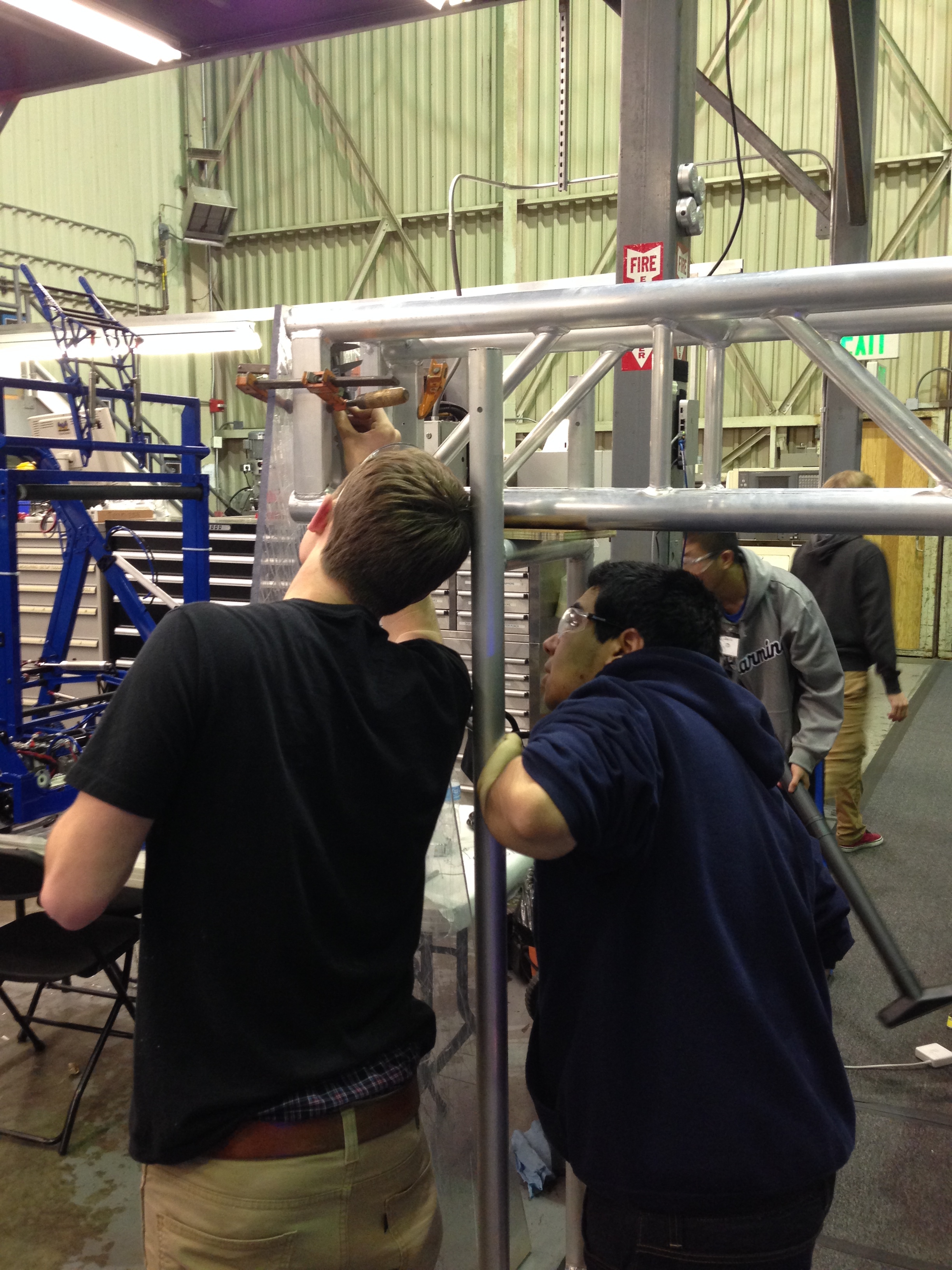

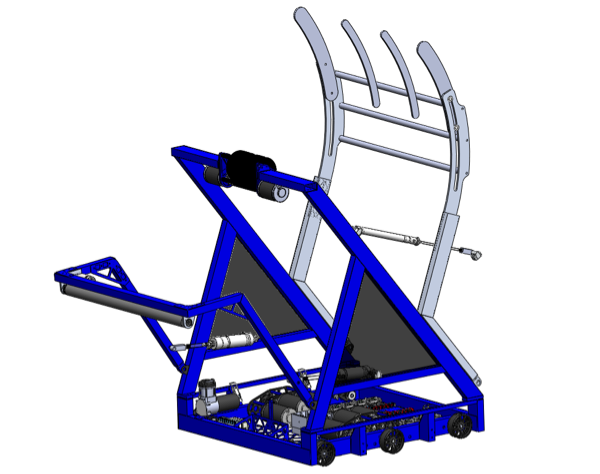

Truss Improvements

In order to make the truss more stable and reliable students made a bar that would ensure that it would work correctly.

Programming

The robot needed a system that would allow it to quickly ready its ball to pass or shoot for a goal. The team programmed the robot so it could quickly move through several pre\-made states and shoot at a goal.

Action Items

- Assemble robot with Mani and Abhi

- Programming with Kevin and Brandon

- Finish bumpers

- Finish truss stabilizer

- Continue control testing

Day 39: Finish Assembly

by Quentin Delephine ’17

Assembly

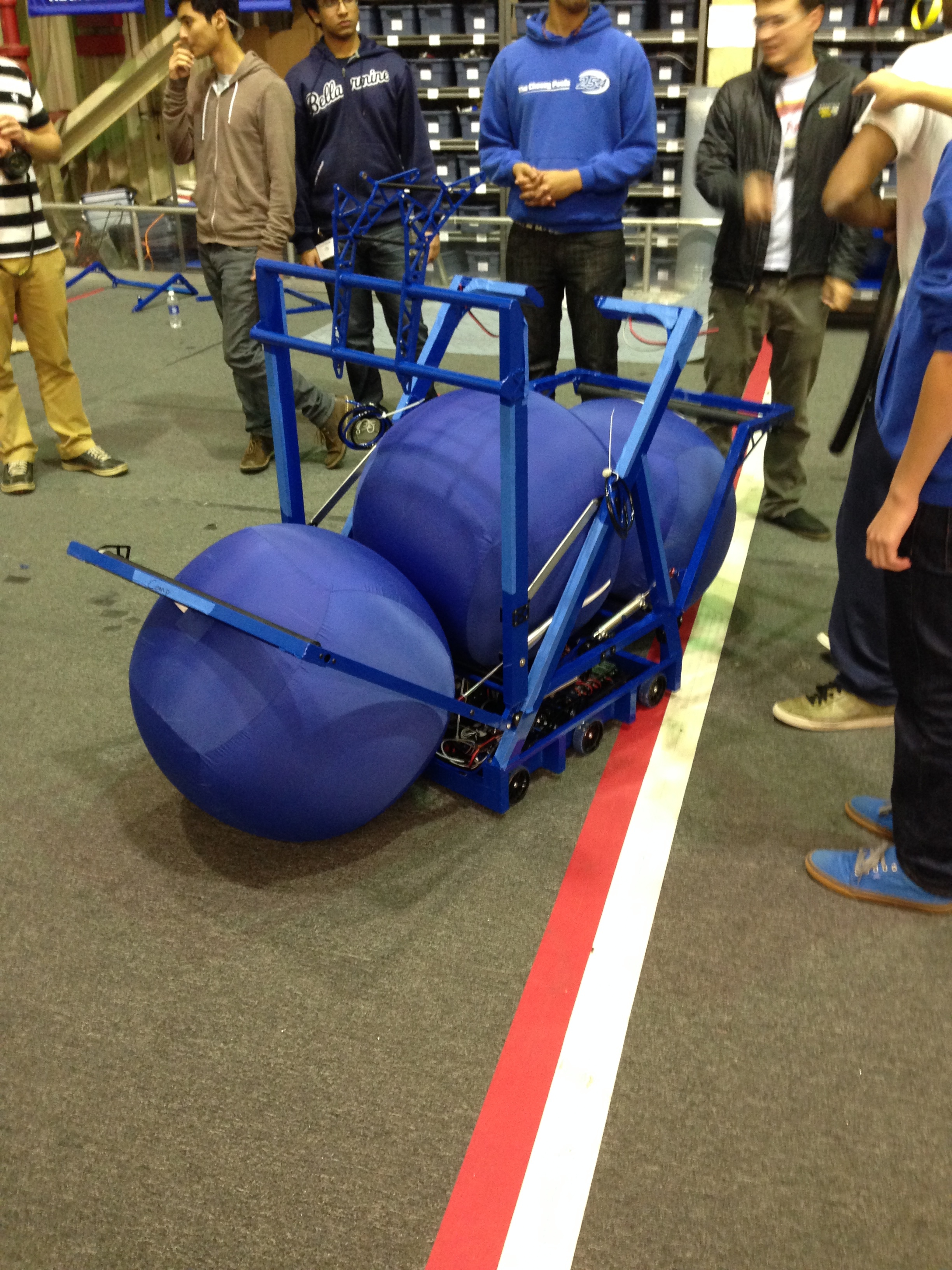

Today the team spent a lot of time assembling both the practice and competition robots.

Students added rubber bumpers to the superstructure using rivets. This prevents the front intake from hitting the superstructure and damaging it.

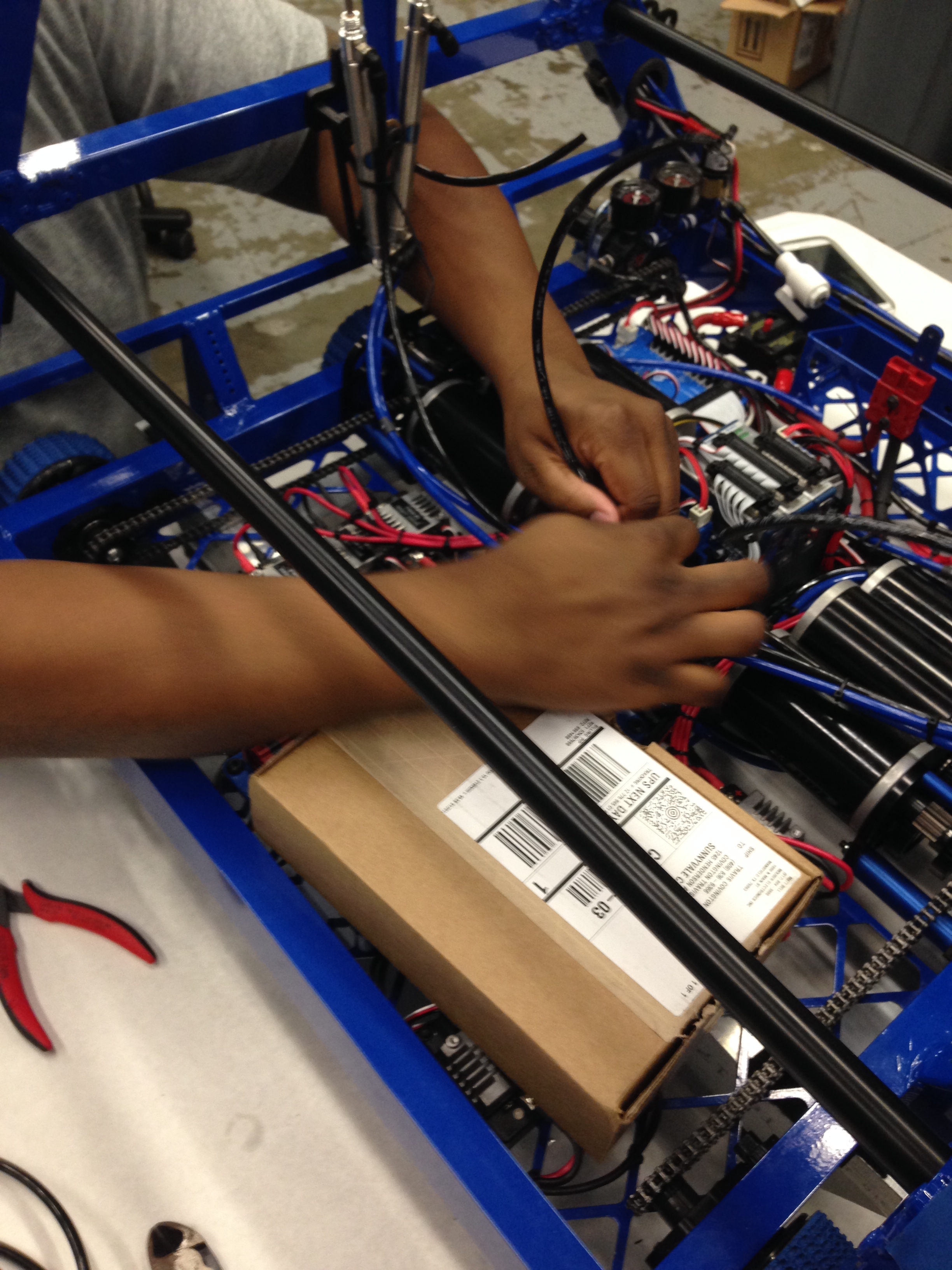

Wiring and Pneumatics

Students helped finish plumbing the pinniped on the competition robot and Practice robot. The two sides of the pinniped can be fired independently. Students also plumbed the cylinders on the gearbox for the competition robot.

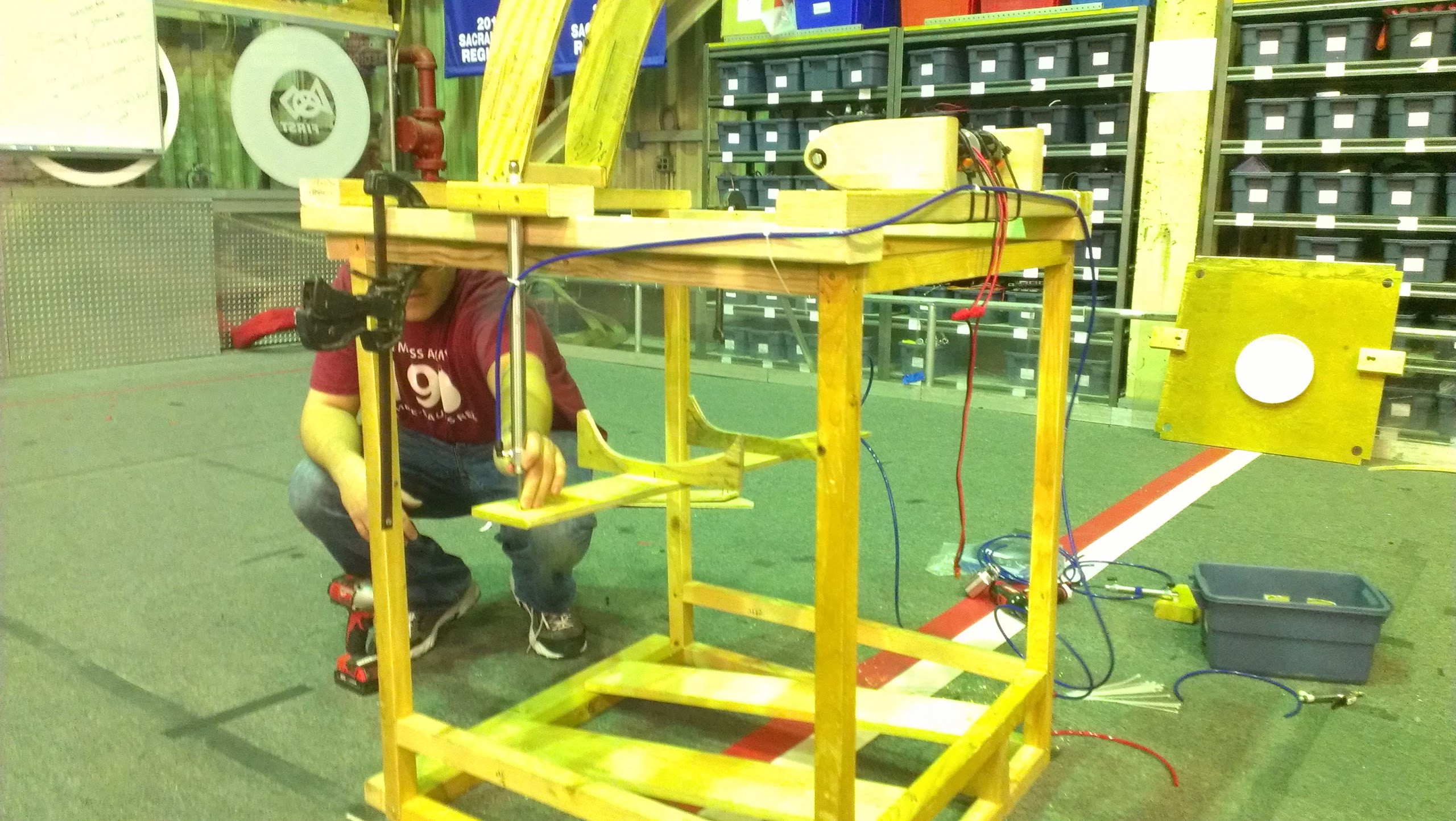

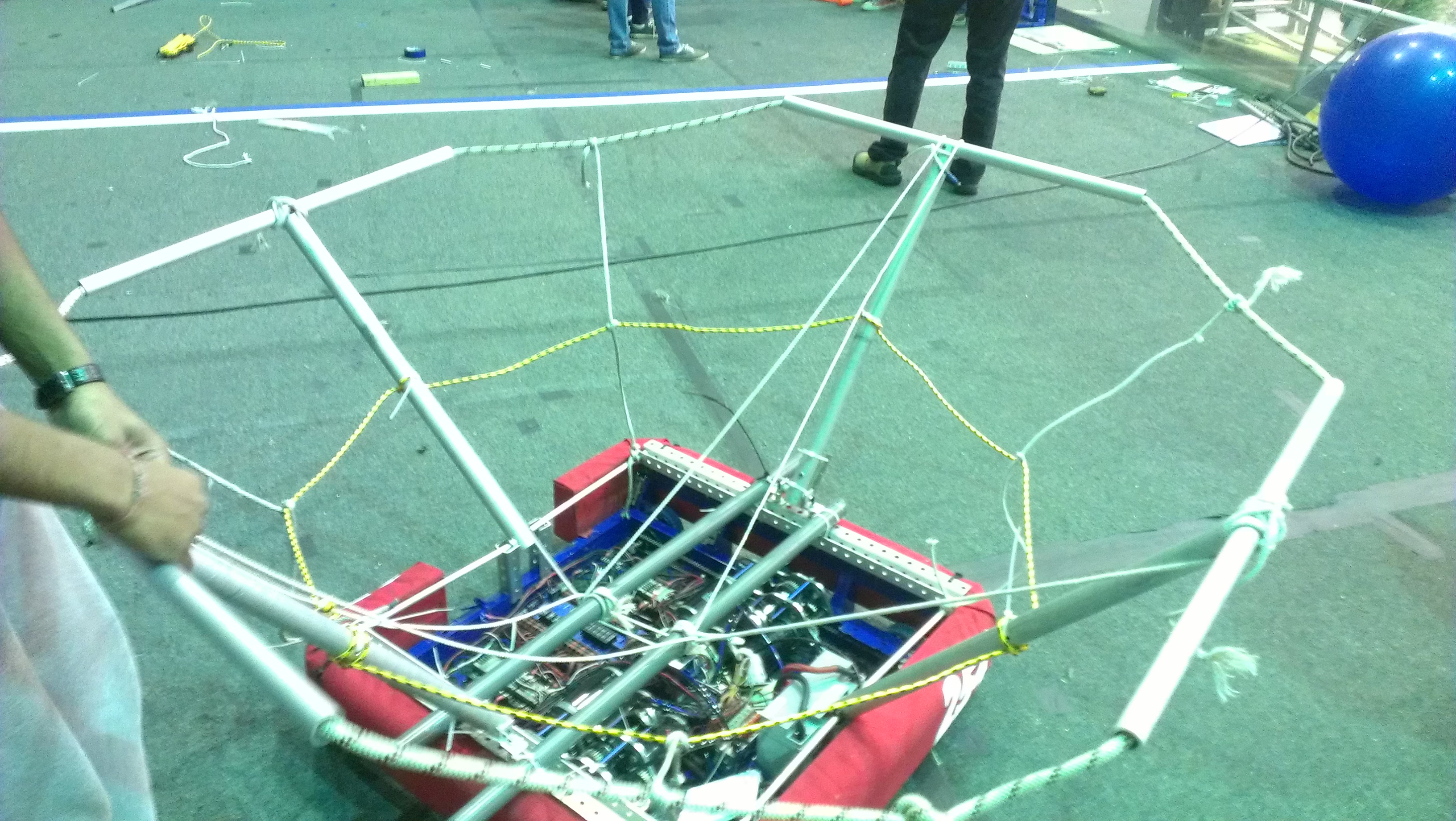

Truss

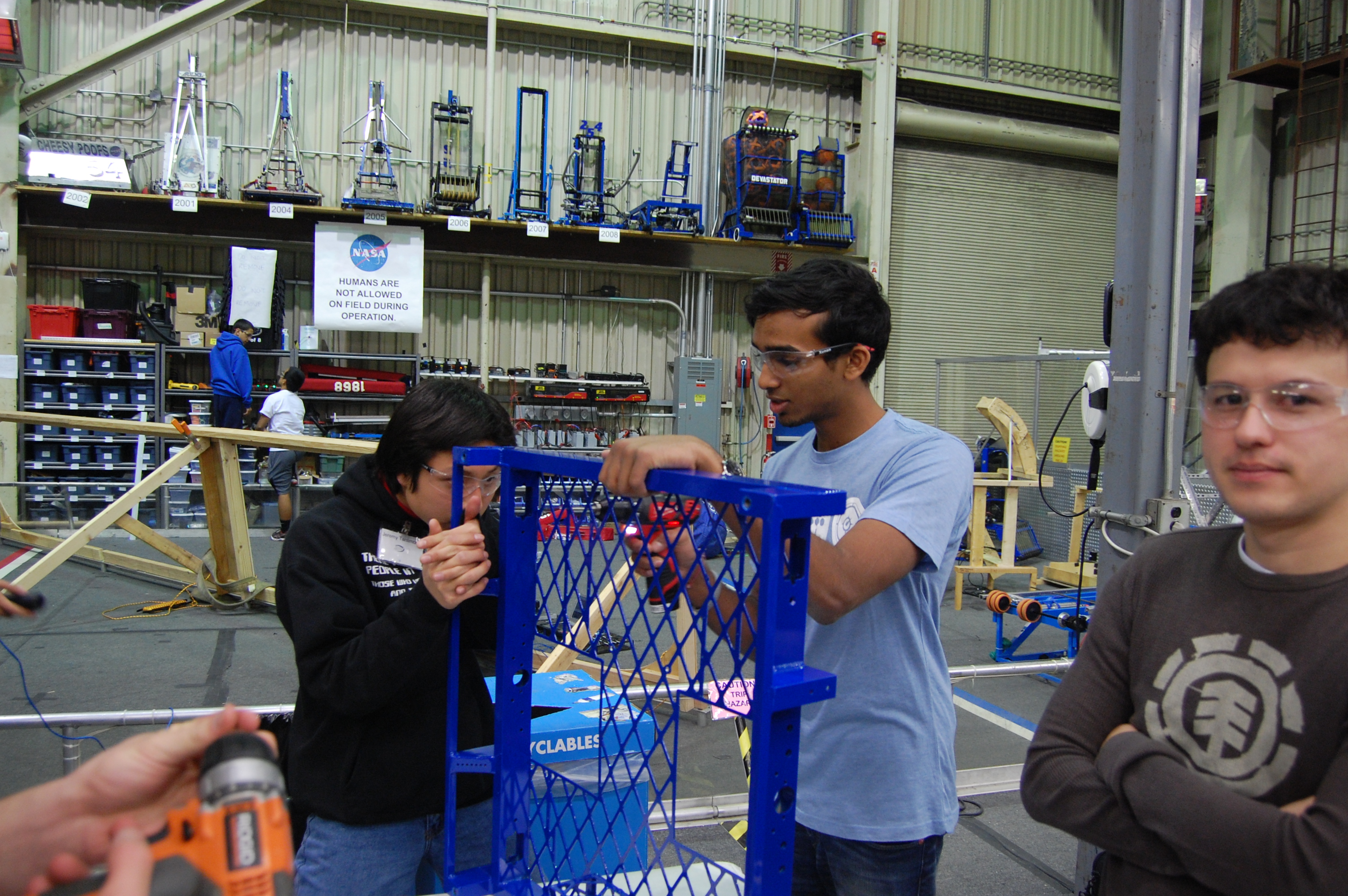

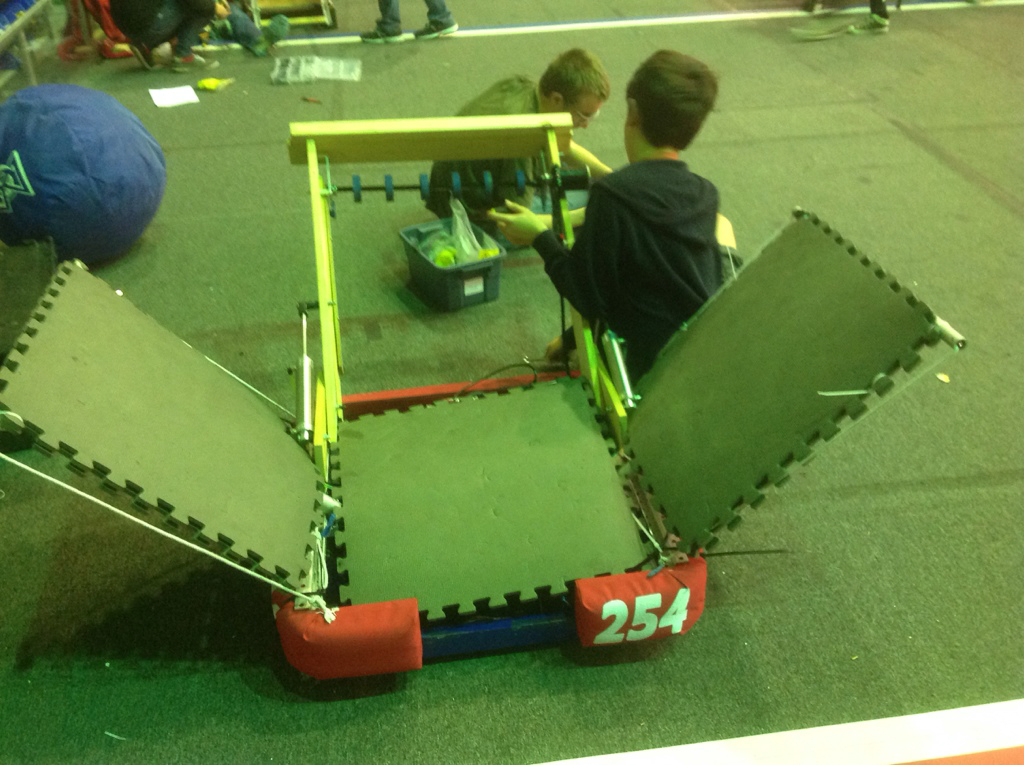

Students assembled the truss, and mounted it on the field.

Testing

The drive base and the pinniped were tested. They worked well and the drivers were able to score in the low goal.

Action Items

- Finish attaching rollers (and motors) to both robots

- Add bumpers to both robots

- Improve Truss mounts and bases

- Complete Plumbing and Wiring

Day 35: Wiring and Writing

by Eliot Smullen ’16

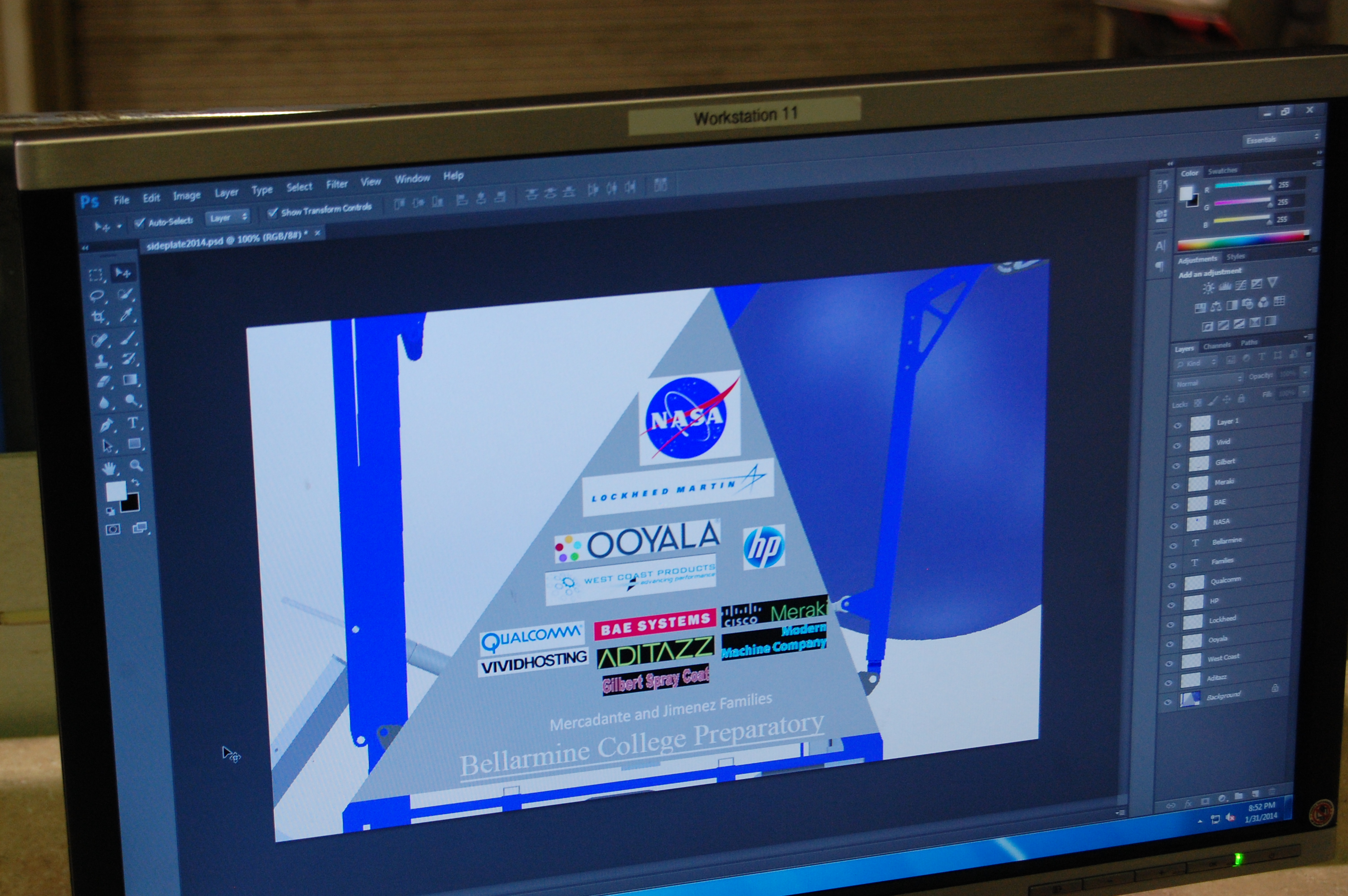

Graphic Design

Several students continued to brainstorm a Waterloo-specific T-shirt. Some of them began considering the issue of whether the back should be left blank if the design on the front were of sufficient size and graphic complexity. The rest brainstormed catchy slogans such as “From C(ali) to shining C(anada).”

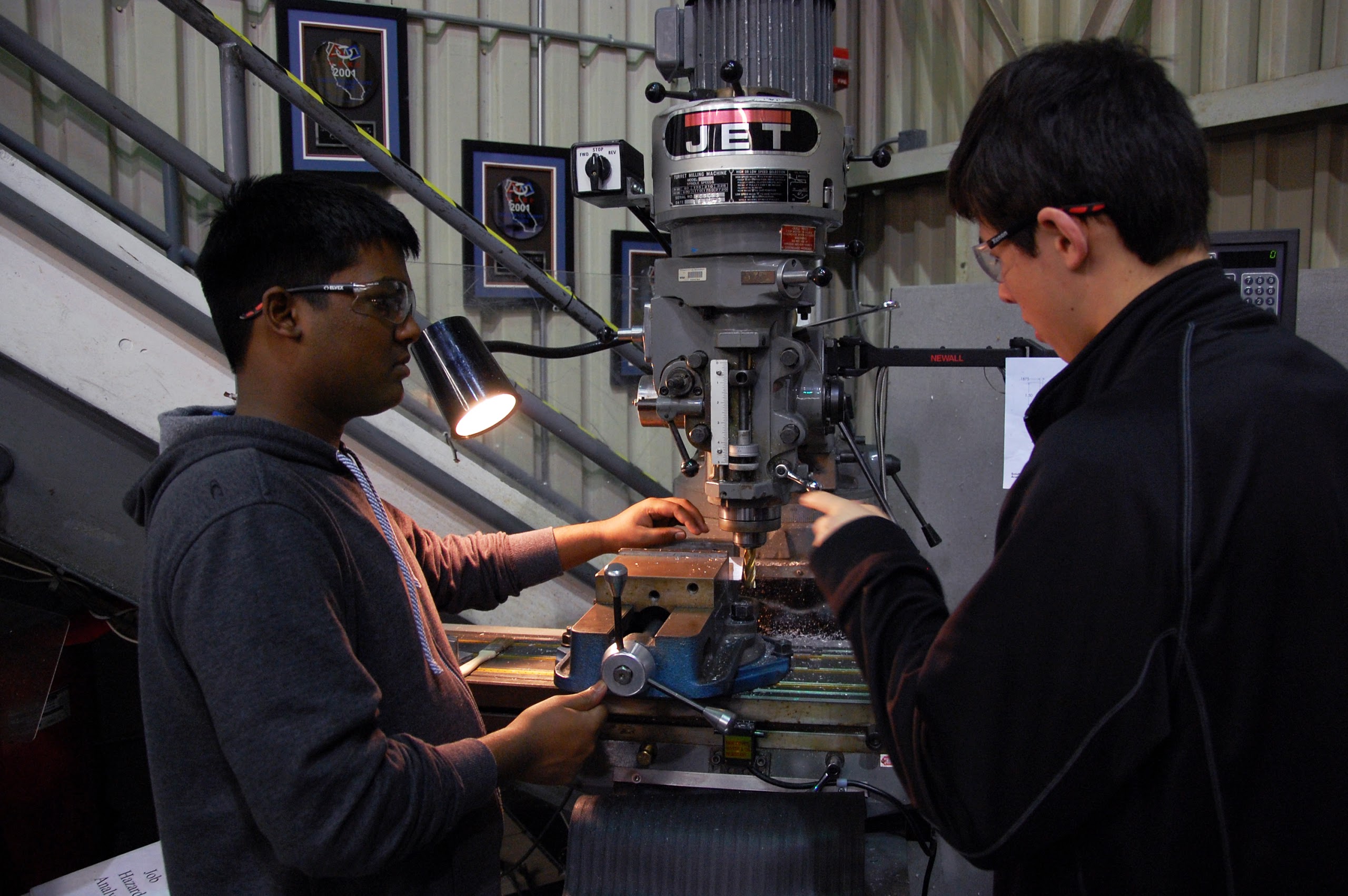

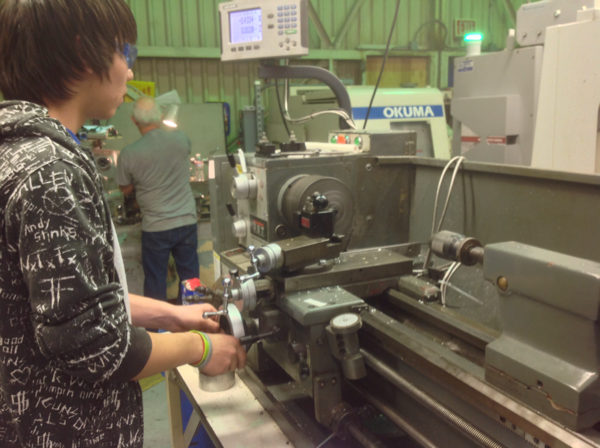

Machining

Today’s machining consisted of creating pulleys for both the intake and the shooter. Also, students begun machining parts for the bumper. The team plans to work on flywheel for the shooter.

Robot Construction

Today, students and mentors worked on constructing the intake for the practice robot. The competition bot has its intake installed and its pressure gauge wired. The practice bot will soon follow.

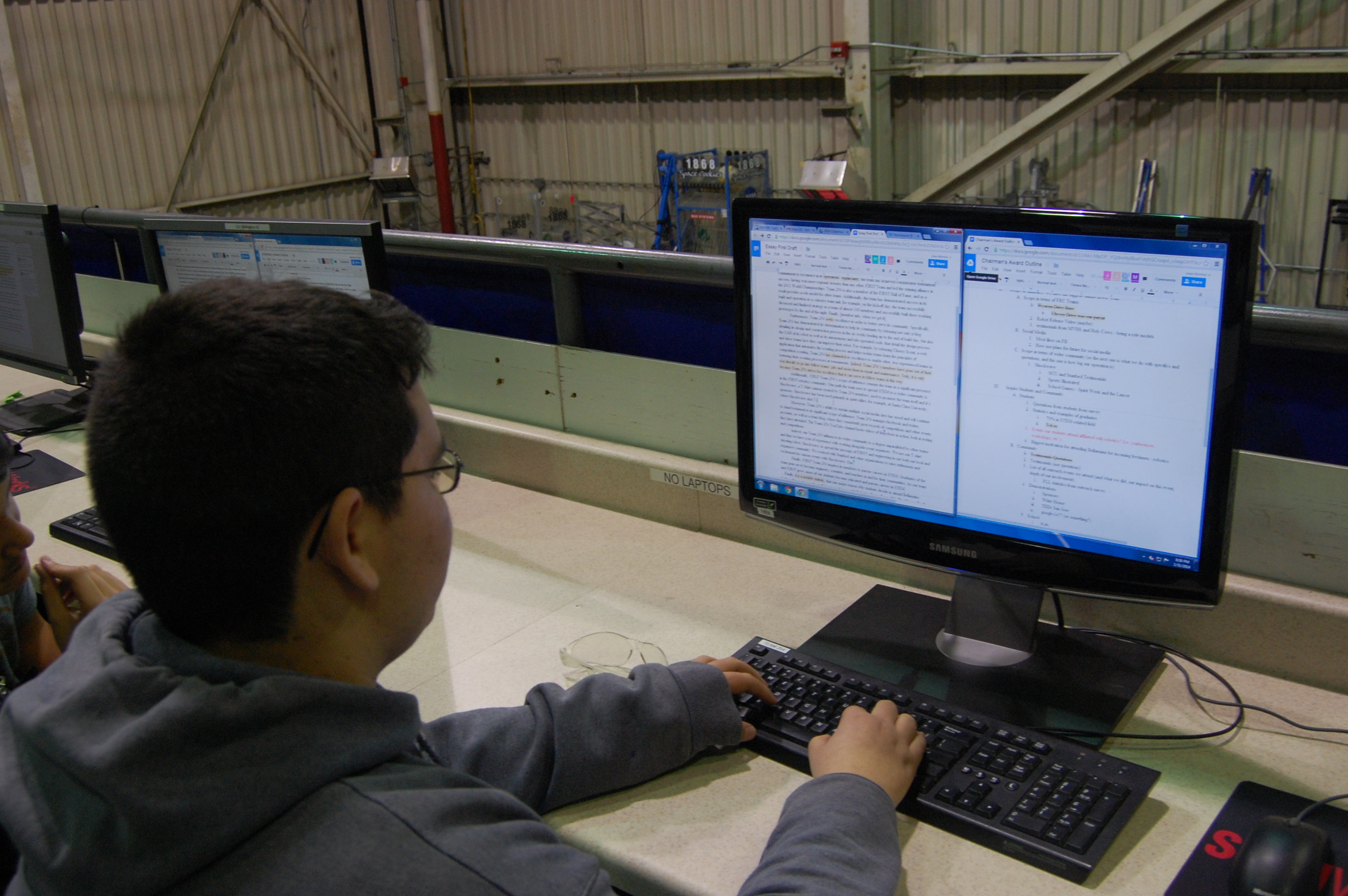

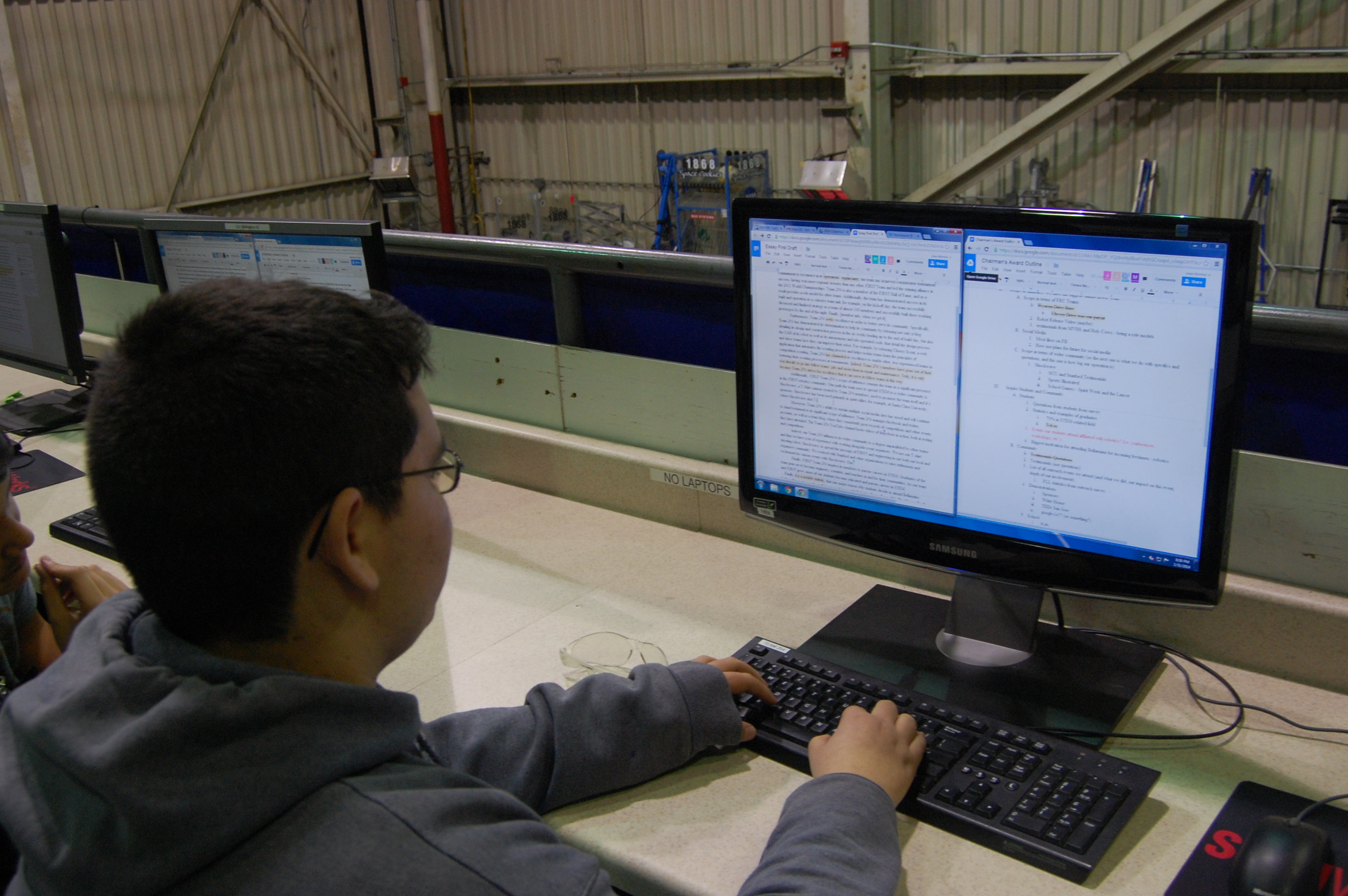

Award Submissions

Today, students worked on our chairman’s submission. However, they still need to edit and add evidence to the essay portion of the submission. In addition, some students began work on the Entrepreneurship Award Submission by matching up sections from the Business Plan written in the first semester with sections and prompts in the Entrepreneurship Award criteria.

Action Items

- Assemble robot with Mani and Abhi

- Wire sensors with Mani and Tom

- Programming with Kevin and Brandon

- Make bumpers

- Check trello

Day 34: Scouting and Superstructures

by Eric Wang ’17

Machining

Today, students manufactured internal shaft\-like connectors for the superstructure. These were designed to give durability to the superstructure when under stress. Also, students machined gussets for the bumper.

Scouting

The scouting team began brainstorming a new method of ranking teams since the traditional method of OPR would not be effective this year. This is still in progress.

Lab Maintenance

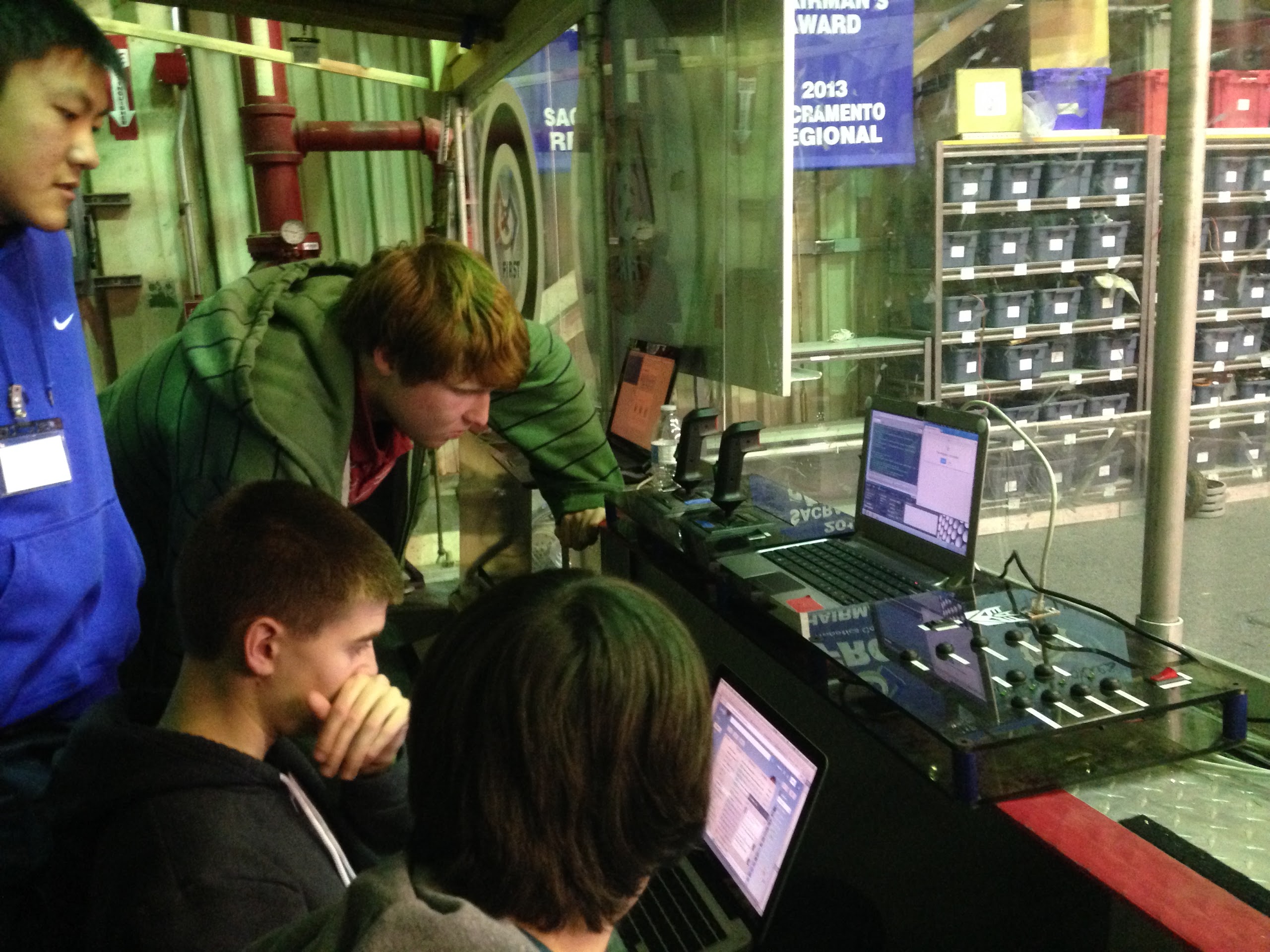

The driver station windows were replaced with brand new polycarbonate windows. These were then meticulously cleaned.

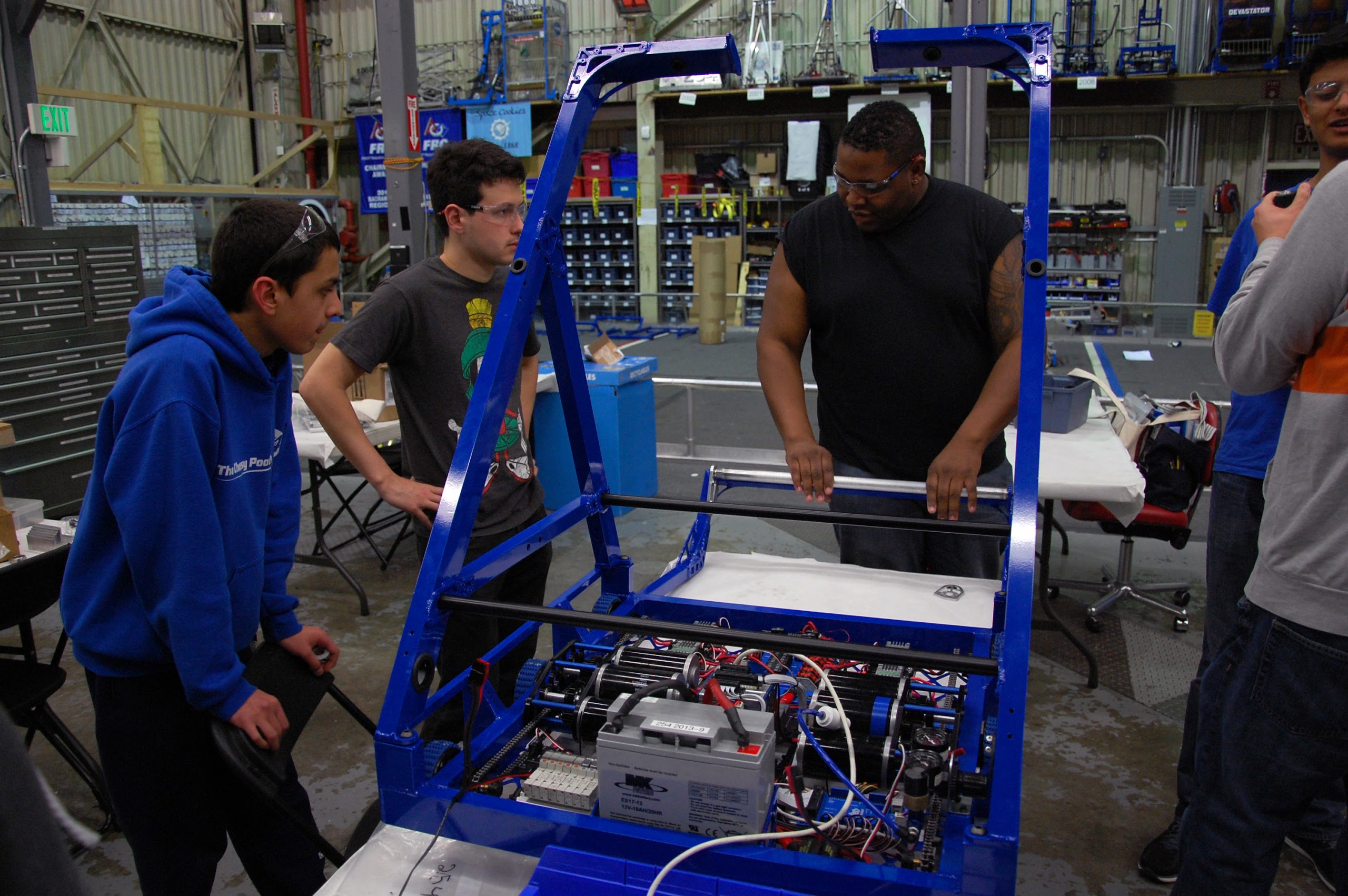

Robot Construction

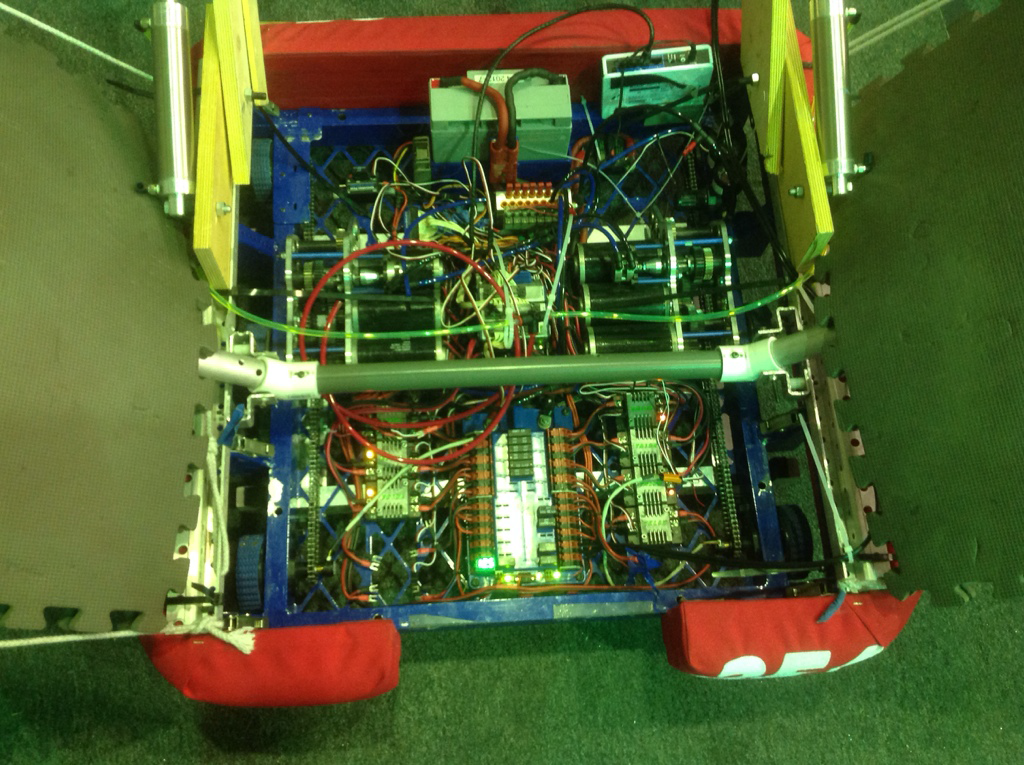

Students and mentors mostly focused on wiring today. The regulator and the router in the drive base frame were wired, along with the wheel encoders. Also, students drilled holes through the superstructure and routed wires and pneumatic tubing for the shooter and other cylinders.

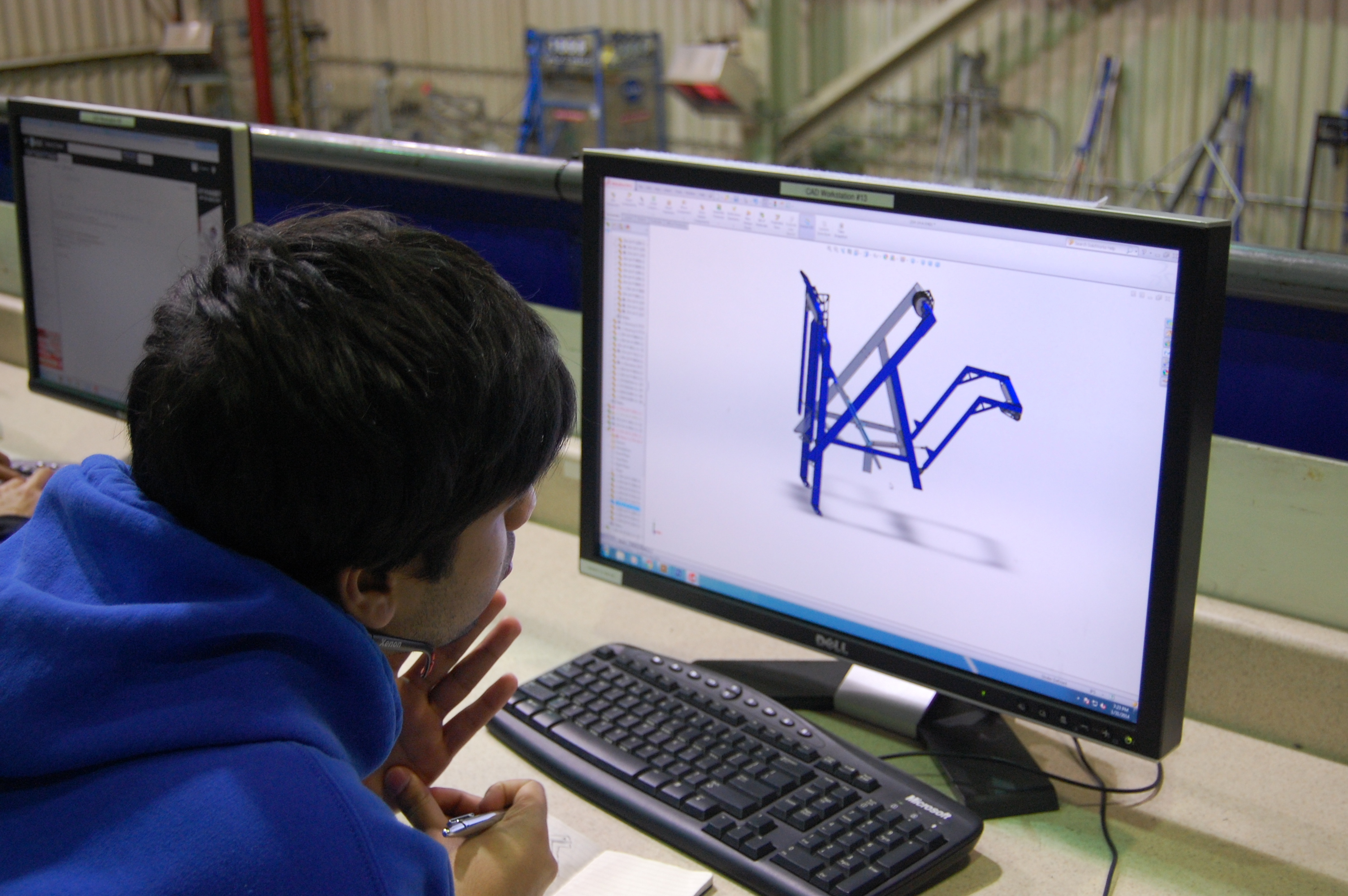

CAD

The CAD team completed part drawings for the robot bumper connectors.

Chairman’s Award Submission

The awards submissions team edited part of the entries that they created previously for the Executive Summary prompts and the major essay \(second draft\). Also, they searched for evidence in previous submissions and changed previous answers to be more direct, so that it would enhance the reading experience for judges.

Programming

The programmers busied themselves fixing bugs and issues in the current iteration of the code. This also involved uploading several versions of the code to the 2013 practice robot.

Action Items

- Work on the scouting system: see Art Kalb for details

- Edit Chairman award submission: see Jeremy Tanlimco for details

- Construct the robot with Abhi and Mani

- Debug code with Brandon

- Check the Trello

Day 28: Coming Together

by Brandon Wui ’16, Christian Jimenez ’16, and Joncarlo Avila ’16

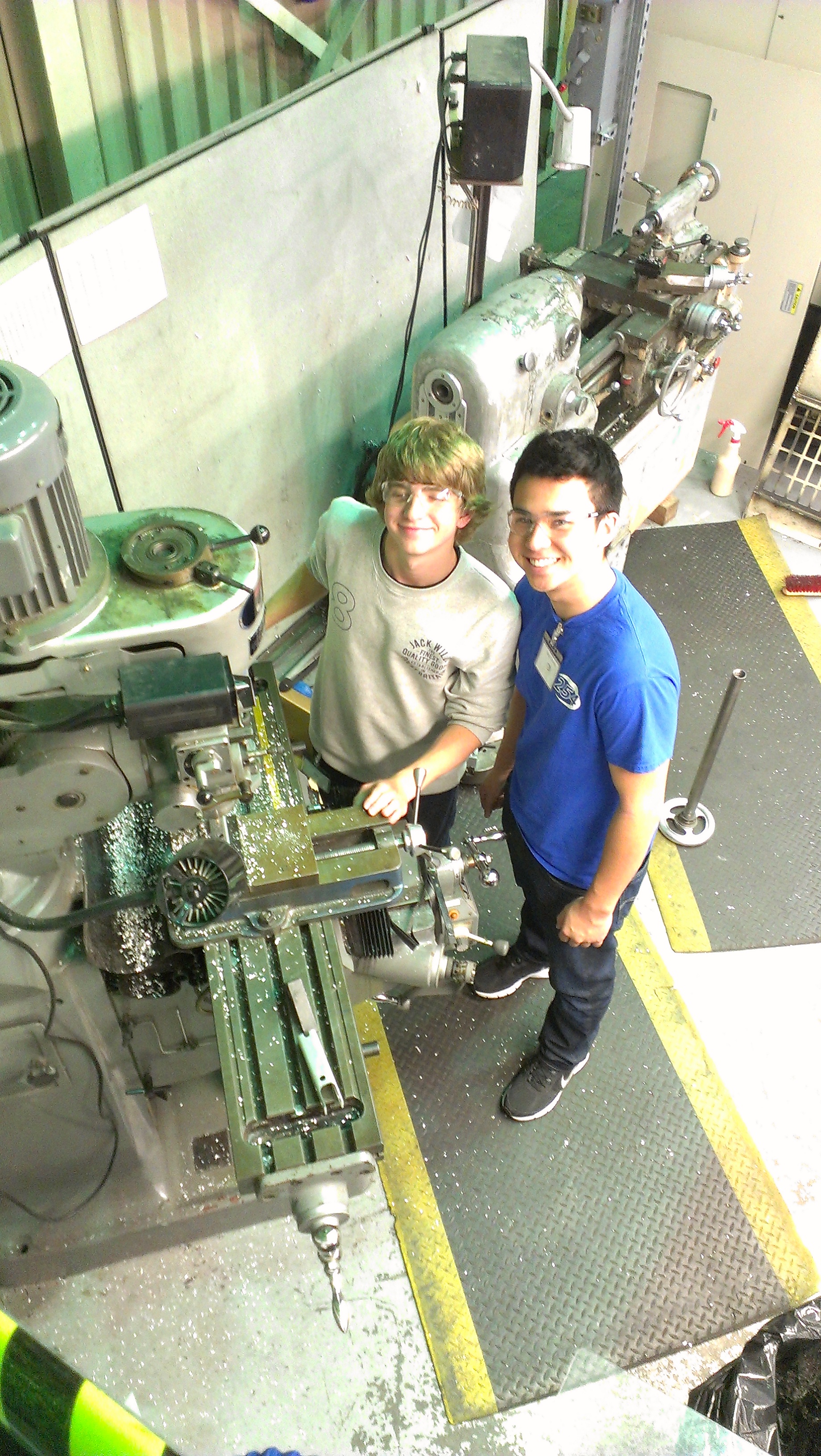

Machining

Today students machined parts for the intake and frame. They also worked on the lathe and band saw to cut pieces and face them for the superstructure. Finally, they drilled all of the holes based on the CAD model.

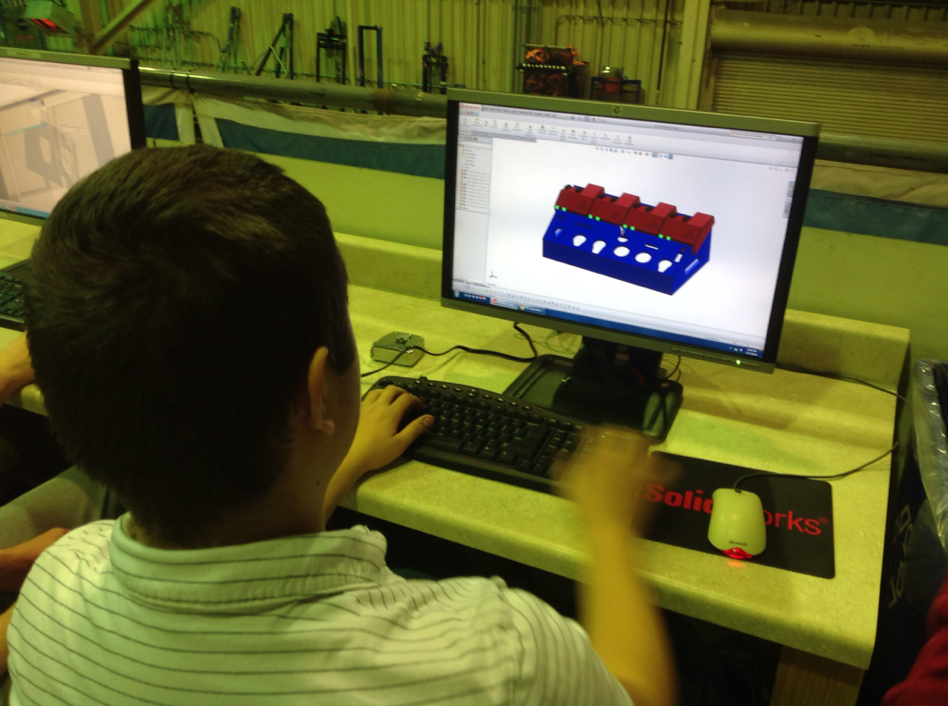

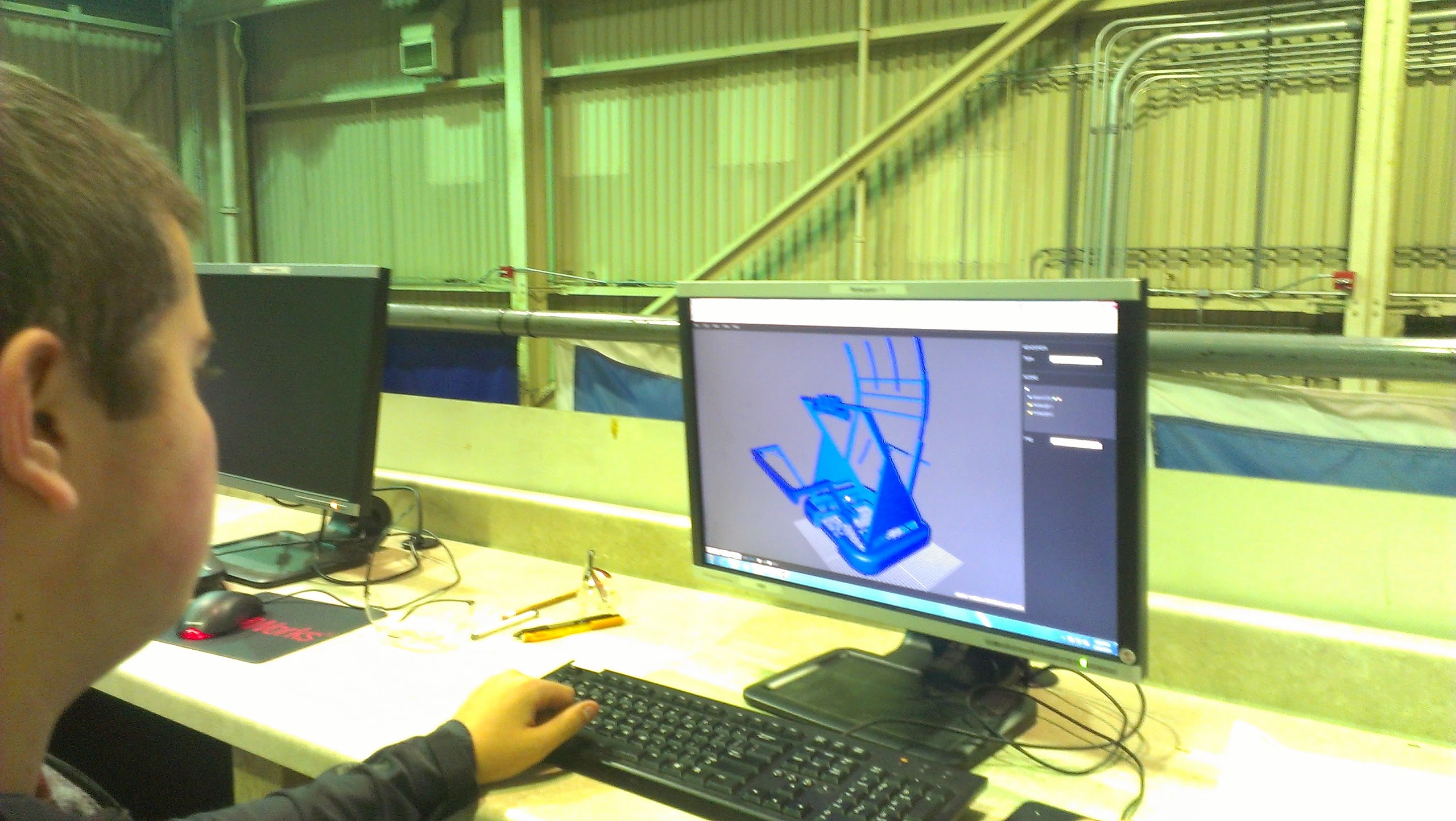

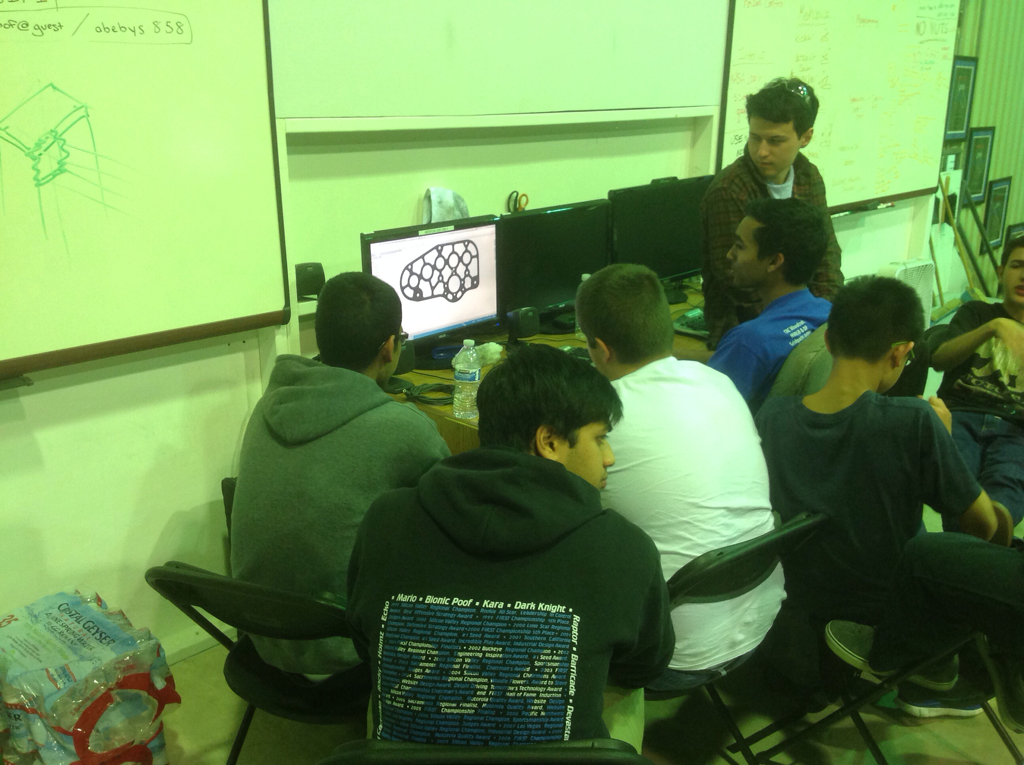

CAD

Today students attempted to add the hot goal sensor to the robot but could not find a good mounting spot. In addition, they updated the shooter design.

Awards Submissions

A group of students worked on the Chairman’s Award Essay. The outline is complete, and the first draft of the essay was finished tonight as well.

Graphic Design

Today, several people worked on graphic design projects for our team such as this semester’s shirt, the side panels for the robot, and the “Silicon Valley Invasion” T\-shirt for Waterloo \(in the spirit of 148 and 118’s “Texas Invasion”T\-shirt at last year’s Silicon Valley Regional\). A student also searched for good fonts for “The Cheesy Poofs.”

Action Items

- Check Trello

- Help Gregorio Magarelli to put together the “Silicon Valley Invasion” shirt on Illustrator

- Help Mani and EJ wire the drivebases tomorrow

- Happy Chinese New Year!

Day 25: Waiting

By Dan Ngo ’17 and Eric Wang ’17

Disclaimer

The WiFi was down in the lab, and the shipment of anodized parts was delayed until tomorrow \(1/29\). As a result, not much work was done.

Programming

Today, the programmers tested a new \(Maxbotix MB1010\) ultrasonic sensor on the robot. This sensor will be used to determine distance to the player station wall in autonomous mode. The sensor was determined to be an improvement over the Vex ultrasonic sensor and two more were ordered. The programmers also continued programming Shockwave’s firing system.

Machining

Also, members riveted the angled 1/8″ brackets to 1×1 tubes to begin constructing the final intake. Eventually, this part will be welded and powder coated. Additionally, students finished the first piece of the drill charger holder, and two more will be machined tomorrow.

Media

Students brainstormed ideas for the robot release video. If anyone wants to help, please ask Maxwell Yun.

Chairman’s Award Submission

Jeremy led a few students with the Chairman’s Award outline offline, and plan to finalize writing by the end of the week.

Action Items

- Continue brainstorming and developing video ideas with Maxwell

- Keep machining and assembling parts for back intake and superstructure

- See Trello

Day 21: Powdercoat, Programming, and Drive base Progress

by James “Mikey” Carroll ’15

Prototyping

Today, a group of students continued to work on and improve the indexer prototype. The indexer, the mechanism used to raise balls into the flywheel shooter, features a claw-like design that lifts the ball as the two arms segments of the claw come together. Furthermore, students improved upon the previous indexer design, which included one piston and two gears, by adding a second piston (one for each claw arm). The intentions of this design are to improve strength and allow each arm to move independently, thereby increasing ball stability and raising accuracy.

Manufacturing

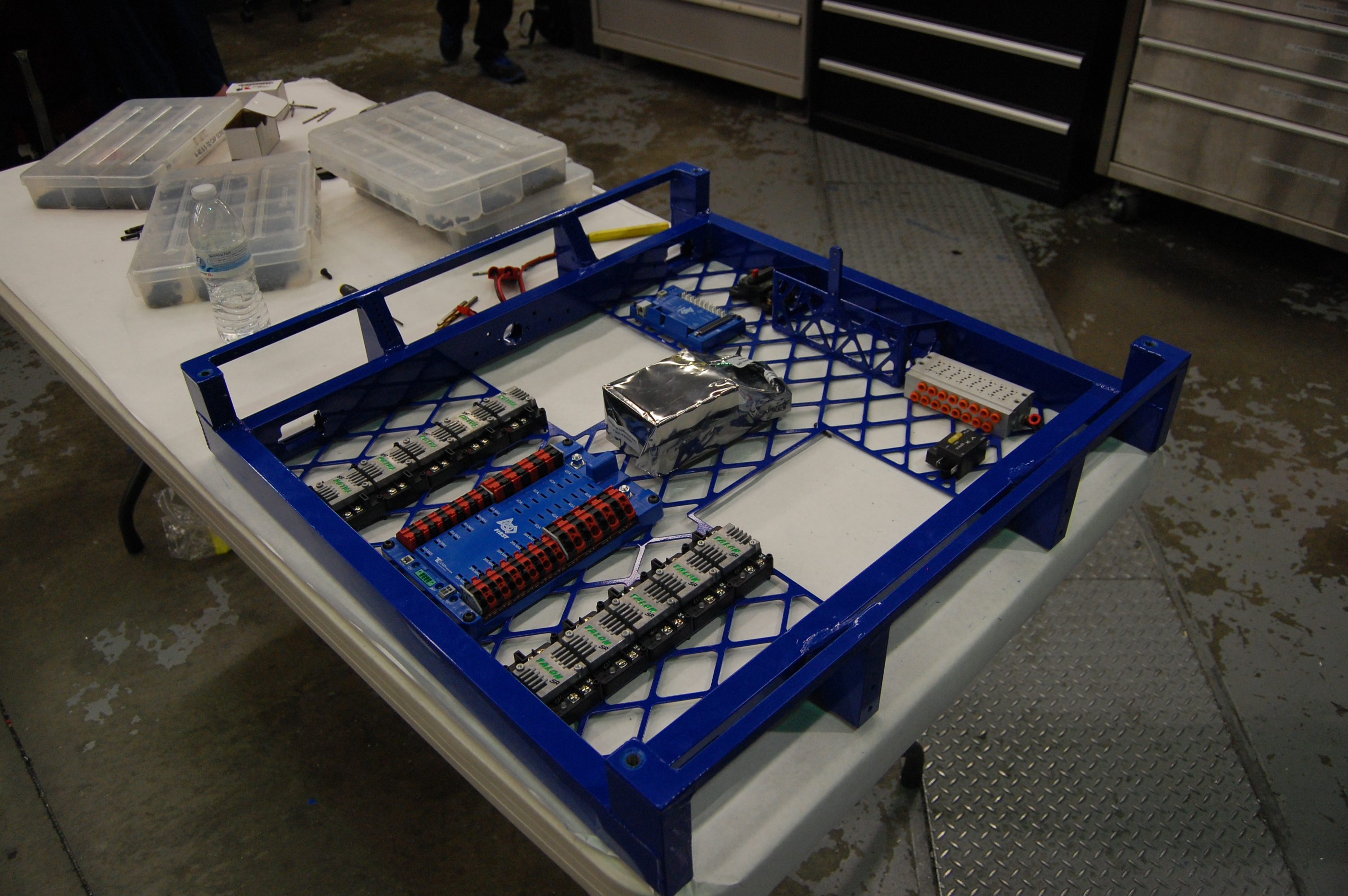

Students began to construct the drive base chassis for the finalized robot. First, students drilled and tapped holes in the chassis, then installed hardware and electronics into the base plate, in particular the main switch, the power distribution board, the digital sidecar, and the Talon motor controllers. Students are beginning wiring.

Programming

Work continued on designing and fine tuning the code for the robot data logger. This log includes information directly from the robot’s sensors, such as drive speed or intake speed. The log also provides easy visualization of all movements of the robot and quickly reveals issues with the robot, such as one motor running faster than another, in real time. Students will also use the information from this program to tune PID.

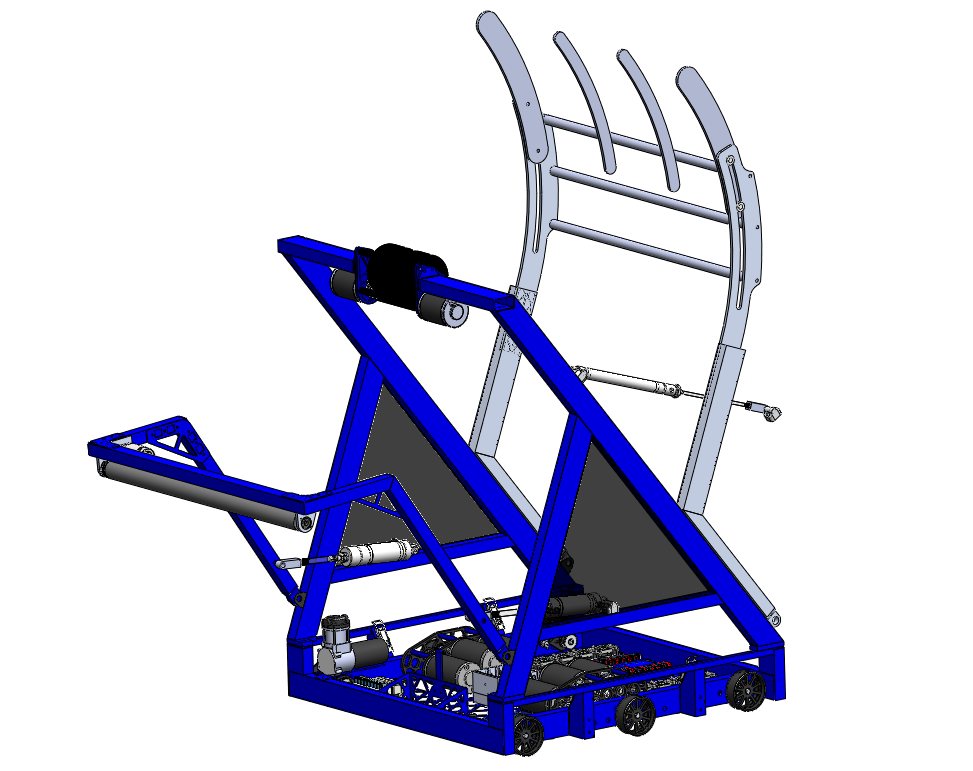

Field Construction

Work continued on the construction of the truss for the field. Students completed a CAD design for the truss.

Chairman’s Award Submission

Students resumed work on Team 254’s Chairman’s Award submission, making lots of progress on the executive summary portion and the essay portion of the entry. Work continued toward a finalized thesis for the essay portion

Action Items

- Add 4 gauge wire to both robots (Contact Mani Gnanavisam if interested)

- Connect Talon motors to PDB and digital side car (Contact Mani Gnanavisam if interested)

- Finish construction of the truss (Contact Mani Gnanavisam if interested)

- Put a backing on the shelf (Contact Mani Gnanavisam if interested)

- Check the Trello (Contact Abhi Kumar if interested)

Day 18: Prototyping, Testing, and Programming

by Chris Powers and Jack Lee

Prototyping

Today, work continued on testing the prototype robot’s lift mechanism, which uses pneumatic pistons to lift the ball from the intake of the robot to the flywheel shooter. This lift worked successfully during most of the tests. The hopper prototype uses a V-shaped mechanism to lift the ball.

Machining

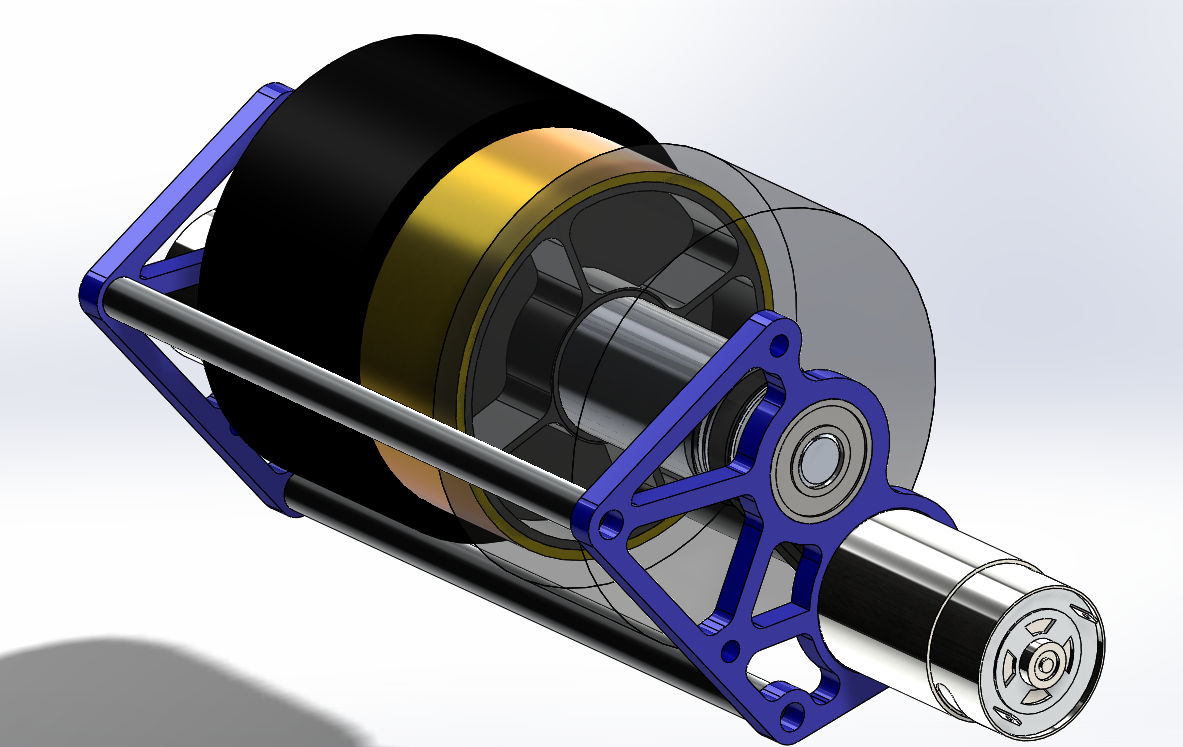

A group of students created side plates for the gearbox. After the plates were cut and deburred, they were machined on the CNC mill. All pieces for the drive base have been manufactured except for side plates.

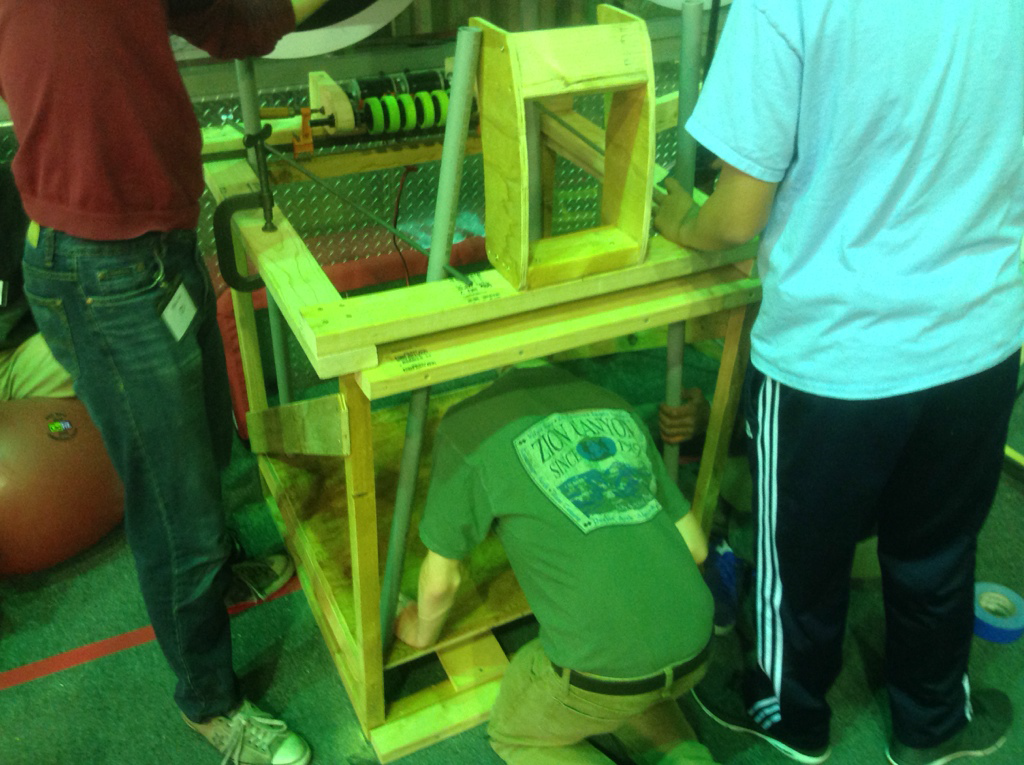

Work began on constructing a truss for the field. Also, the wooden goal was disassembled and the official goal will soon be set up.

Programming

The programmers worked to fine tune the shooter mechanism. They created a graph of the model voltage for the shooter and compared it to the actual data with equations. This will allow compensation for the variable factors that affect the input voltage, and will increase shot accuracy.

Testing

Many students contributed to testing and refining the shooter mechanism. Many different variables were adjusted to determine the best conditions for accurate and powerful shooting. The shooter speed was varied between 4000 and 5000 rpm and the wheels for the shooter were replaced with slightly larger ones to increase flywheel energy. A banner sensor was added to measure flywheel rotational speed using retroreflective tape. The new flywheels shoot 12 vertical feet, high enough to clear the truss.

CAD

We began work on the design of a new prototype shooter. This shooter will have a sturdier hood and a lighter wheel. The hood will also have a hood extension that can be attached to replicate the two-position hood on the actual robot.

To design the shooter, students learned about moment of inertia and used SolidWorks to roughly estimate the mass and moment of inertia of the current extra weights on the shooter prototype. We used those numbers to estimate the mass and moment of inertia that we can add to the flywheel in place of the metal gears currently in place on the shooter. These numbers allowed us to model a copper tube with less mass and a similar moment of inertia which will be pressed around an aluminum hub and installed on the robot. More information on moment of inertia is available online.

Action Items

- Check the Trello

- Assemble the weldment

- Start on catcher prototype with Colin

- Test the new shooter wheel and new prototypes thoroughly with Abhi: build adjustable hood for testing shooting angles: test for shot distance for hood angles and ball pressure

- Complete CAD of bumpers, superstructure, and battery cart with Andrew and Mani

- Possibly build new flywheel weight.

Day 14: Working Robot Prototype, CAD, Chairman’s Award Begun

by Christian Bagamaspad and Michael Simeon

Robot Prototype

The robot prototype changed considerably today. First, the shooter prototype was mounted to the 2013 drive base. The robot can now drive, intake, load the ball, and shoot in one test. Results were very promising and tests showed the robot can pick up and hold two balls, sequentially index and shoot them into the goal. Later, shots will need to be fired more consistently, and the “popper” piston mechanism will need to be more robust to provide better shots and prevent the ball from getting jammed. This mock up prototype of the robot could possibly be used by programmers for early autonomous testing. This is one of the first times in recent years that team has built such a large compilation of other prototypes. Due to the simplicity of its design compared to previous years, this prototype will actually be somewhat similar in functionality to that of the final robot.

CAD

Today, the CAD team worked on the ball lifter assembly and piston positioning for the 2 position hood. We also went through the drive gearbox CAD to ensure everything is in ship shape before manufacturing begins.

The team also worked to finish up the 3D model of the cordless drill holder, finalizing the hole placement and overall ascetics. Once approved, the CAD model can be sent to Good Plastics to have it routed.

Additionally, others started work on the control board CAD, starting with the process of designing the control board plates itself. They also found and selected all the screws for the control board. Next, the control board’s button layouts will need to be designed and modeled.

Award Submissions

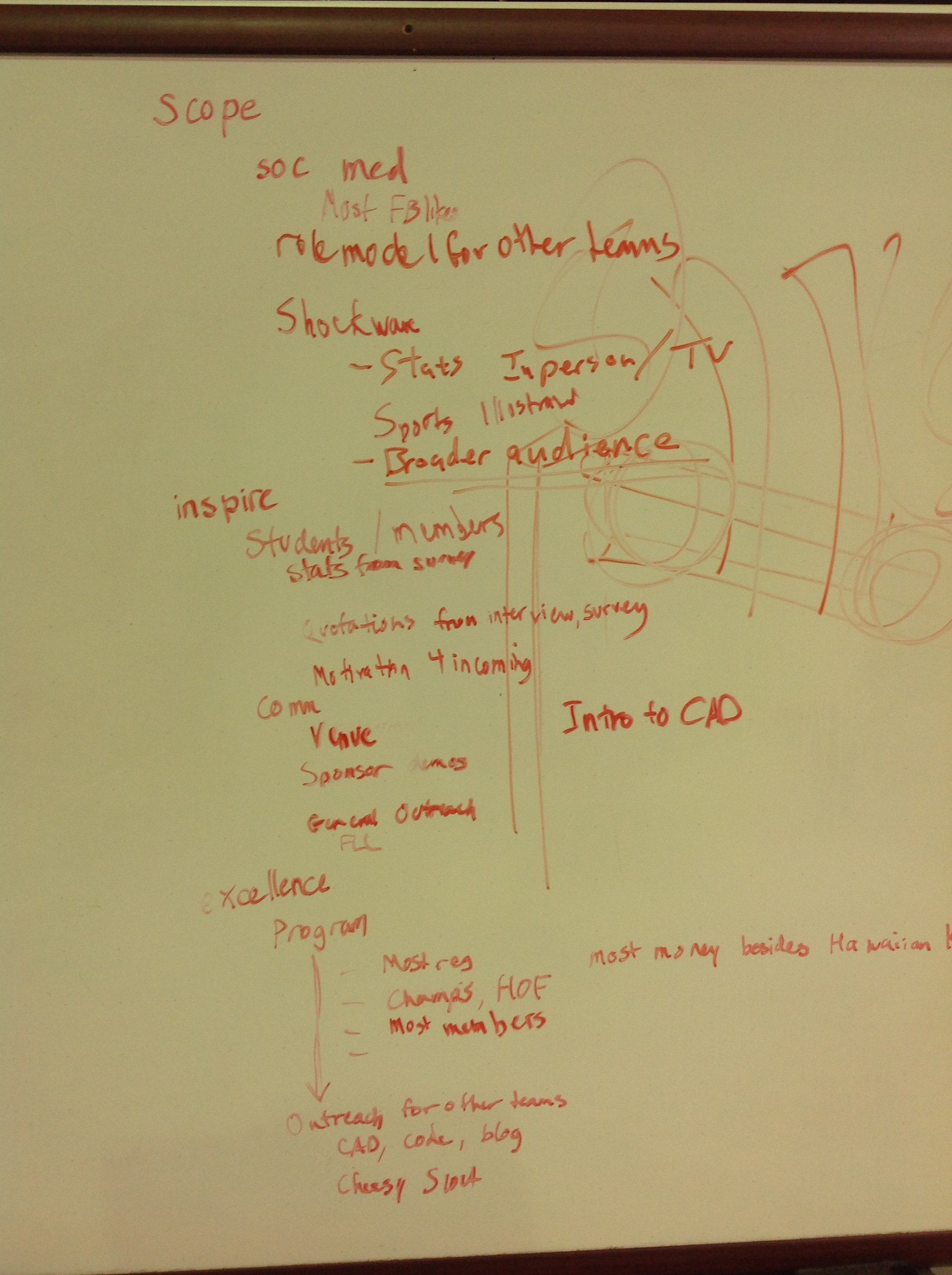

The drafting of the Chairman’s Award Essay thesis began today. Team members brainstormed and wrote tentative theses in preparation for outlining over the weekend. Additionally, they also reviewed previous submissions for the Chairman’s Award and discussed the implicit intent of the thesis. They decided that the underlying message of the essay should emphasize the development of the team since its 2004 Chairman’s Award victory and how the team has continued to set a new direction since then. The team also plans to portray how it has further emphasized outreach and how inspired others in our local community and abroad.

Manufacturing

Today was a slow day on the manufacturing front. The primary task of the day was shortening the drive gearbox piston spider standoffs.

Pit shelving

Today, students worked on organizing the pit storage shelves. Prior to today’s work, the shelf storage had been bound by tape, but now, the tape has been replaced with Velcro straps and certain beams were marked to point to the holes used in assembly. This will help save time during pit set up and tear down and prevent us from having to keep reusing expensive tape to simply bundle the segments together.

Action Items

- Check the Trello!

- Test and improve intake and shooting mechanisms on the robot prototype

- Finalize and approve the model of the cordless drill holder to be sent to Good Plastics

- Look through the website and all its pages and condense into a Google Doc a list of everything outdated, inaccurate, or otherwise unfit for the website.

- Organize outside storage area to make obtaining materials faster, simpler, and safer.

Day 13: Intake Construction, Flywheel Prototype, CAD

by Jeffrey Kaufmann

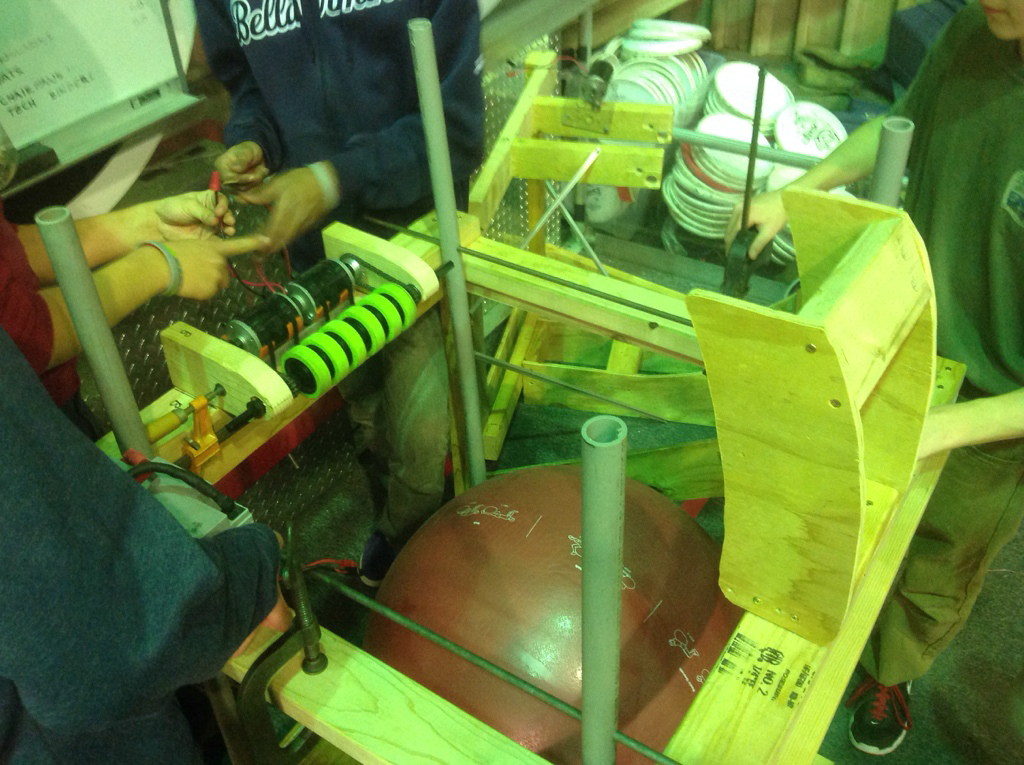

Flywheel Prototype

Today, work continued on the automated ball loading mechanism for the flywheel prototype. This “popper” will use two pneumatic pistons to quickly and precisely load balls into the shooter for more consistent and realistic testing. Tomorrow, the entire shooter will be mounted on top of the robot drive base along with the intake and to test the integration of the three systems.

Intake Construction

Other team members worked on creating a new prototype intake. This intake was created to the dimensions currently in place in the robot CAD model. It will be able to flip down with two pistons. The intake will utilize one mini CIM motor to drive the roller. When the intake is down, it can suck a ball and pull it up against the bumper. When the intake comes up while holding a ball, it pulls the ball into the robot. This will later be integrated with the shooter and “popper.”

Later in the night, the intake was finished and tested with the robot driving around. While this test did not utilize pneumatics, it did show that the intake successfully could pick up balls both while stationary and moving.

CAD

We also worked to create 3D render of the robot that can be used for the touch screens in the pit. Specifically, we worked to convert the current CAD model of the robot into a website that can be manipulated on a touch screen. This will be a fun, interactive way for visitors and judges to explore the CAD model of our robot.

In addition, we continued work on the Cordless Drill Holder. Some students were finishing up the CAD upstairs and figuring out the final dimensions so the organization unit can fit in one of our travel crates. Others were using the drill press and mill to make precise prototype holes in wood for the drill chucks to fit in. These test pieces were then used to get accurate dimensions in the CAD that will be later sent to Good Plastics to be professionally routed in blue HDPE plastic.

Action Items

- See the Trello boards!

- Continue work on Intake construction

- Keep testing 3-D render

- Finish Flywheel Shooter Prototype and integrate with Intake prototype and Overkill drive base

- Finish CAD of Cordless Drill holder

Day 12: Design Review and Further Prototyping

by Dan Ngo ’17

Design Review

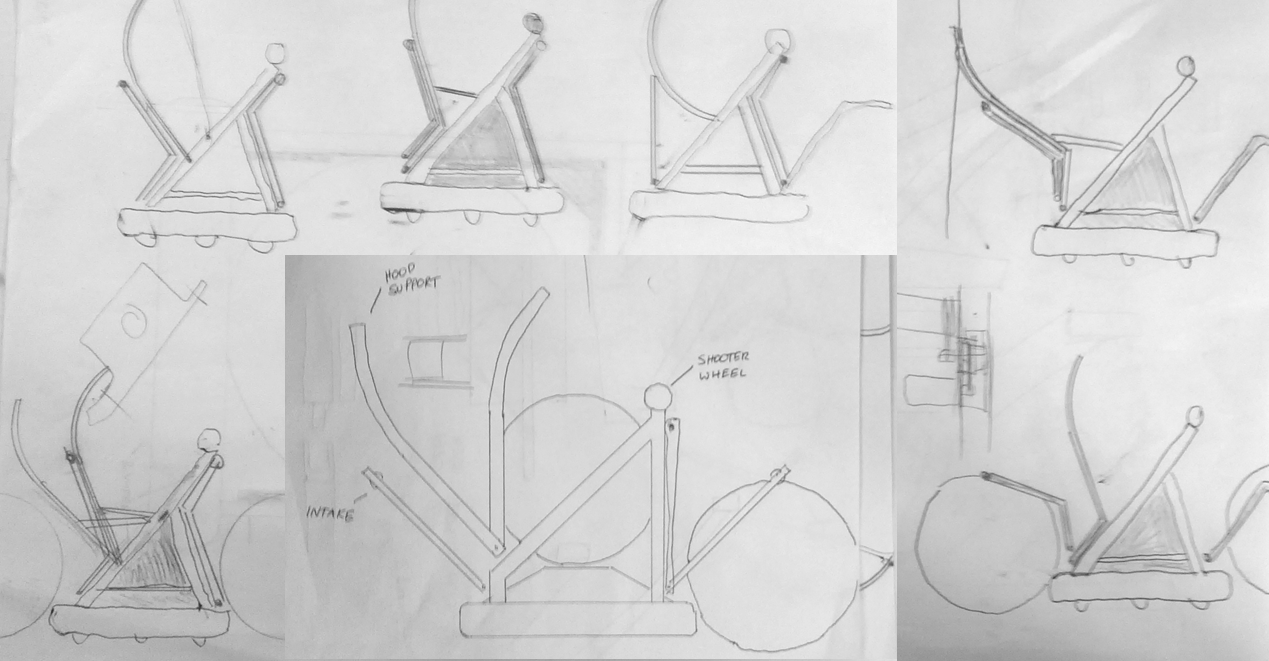

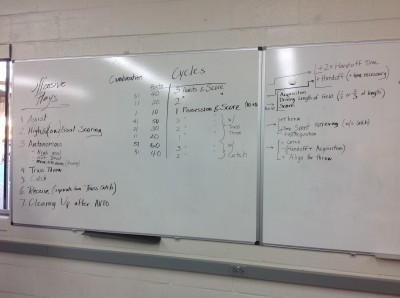

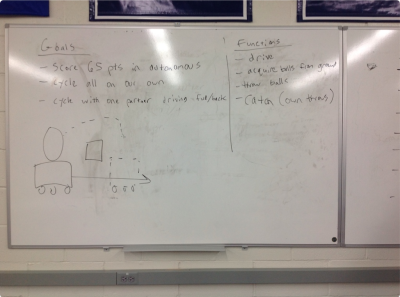

The highlight of the day was the design review, during which the team congregated to discuss and possibly finalize the strategy and conceptual robot design thus far. The team decided that its overall strategy would be aimed at being able to first self score all three balls in autonomous. This removes any risk of relying on teammates during this valuable portion of the match. Subsequently, in teleoperated mode, general scoring would be prioritized. Assisting, while useful for qualification points, will likely only become significant in elimination matches.

Regardless of strategy, we agreed that the robot should be able to perform all the tasks in the game (shooting, passing, catching, etc.). We determined that a flywheel shooter aligns with these goals and packages nicely in the robot’s envelope. Additionally, to be able to score all three balls in autonomous, the team would first need a mechanism to hold and feed them into the shooter. This is currently being prototyped.

Programming

Team members continued work on integration of the ultrasonic sensor. We also worked on making programs to remotely access feedback from the robot, to ease autonomous testing. We also installed new, smaller, joysticks on the control board. These joysticks use hall effect sensors instead of potentiometers for more reliable and precise control.

Manufacturing

Today, groups worked on machining parts for the gearbox, the ongoing arm prototype, and started the feeding mechanism prototype.

Action Items

- Continue intake prototype

- More testing and coding

- Work on the feeding mechanism prototype

Day 11: Prototyping, Design, CAD, and Testing

by Trevor Salom ’17

Programming

Today, the programmers worked on testing a VEX ultrasonic sensor to see whether the robot could use it to gauge its distance from the wall of the field. The VEX sensor was used as a temporary stand-in while the programming team awaits the arrival of the competition sensors.

In addition, they continued working on applications to graph the feedback sent by the robot.

Design

Today, we continued the design of the robot and continued detailing the main intake, the shooter wheel and the actuating hood. The shooter is powered by two mini CIM motors with power transmission through small GT2 timing belts. The front intake has a 550 motor mounted on the end of the arm with a two-stage belt reduction aimed to give a roller surface speed around 15 ft/sec. This speed was determined by estimating the average robot speed while intaking (10 ft/s) and determining the amount of time we hope for an intake to take.

Furthermore, we finalized the design of the baseplate and continued work on the design of a drill holder.

Manufacturing

Today, we began making the outer bearing housings. A large order of material arrived today from our aluminum supplier. The aluminum plate for the robot bellypan was dropped off at sponsor BAE systems for waterjet cutting. We expect the baseplate to be cut on Monday.

Furthermore, a number of team members cut tread today. This tread will be used on practice wheels for existing robots and may eventually be placed on the competition robot (once its wheels are made).

Roller Intake Prototype

Work was also started on building a more refined version of the roller intake prototype. The intake will be raised and lowered by pistons, and will be based on a CAD drawing of the final design.

Action Items

- Finalize Robot Design and CAD under Andrew Torrance and Mani Gnanasivam

- Refine Intake Prototype under Dan Judnick

- Programming and related testing with Brandon or Stephen

- Help out the Media Team under Kevin or Maxwell

- Ask a leader or mentor or request access following the instructions on the whiteboard to see what other tasks are listed on the Trello.

Day 8: Prototyping and Miscellaneous

by Christian and Michael Simeon

Catcher Prototype

Today, students lined the catching prototype with VEX field flooring tiles to help keep balls in the catcher by preventing them from bouncing off the PVC pipes and rope. Students also improved on the attached intake prototype. Additionally, they attached gyroscopes and encoders to allow the prototype to better recognize angles and ultimately better function. Students have begun testing for those encoders and gyroscopes added to the drive base. Sending data from the encoders and gyroscopes to a web browser with graphs and statistics on the robot will help with fine tuning the prototype.

The Shooter Prototype

An elevator system with metal bars and PVC has been added so that balls can be more consistently fed into the shooter. Additionally, the arch on the top of the shooter prototype has been modified. Later, metal and PVC were removed and replaced with a frisbee and cables.

CAD

Today the people working on CAD continued working on drive base. They mirrored the gear box for the other side of the robot and added it to the drive base CAD. They also added the electronics and other necessary components. Finally, they also made part drawings for spacers in the gear box.

Team members also continued thinking about packaging options for the superstructure. We have decided on having three pivoting arms for the robot’s two intakes and catching hood. All arms will be piston-actuated and are designed to fit within the 20″ extension rule. The intakes are bent to allow for rollers to contact balls as the robot spins to grab a ball. With straight bar intakes, the bars could push balls out of the way of the intakes.

We also discussed mechanisms for locking the hood in place during shots to prevent the balls from pushing against air pressure to reduce hood compression. Discussed mechanisms included an over-center piston linkage and a locking piston mechanism. We will likely move forward with the locking piston mechanism.

Miscellaneous

Students and mentors worked on the lathe to create standoffs for the gear box. Additionally, work continued on submissions for the Entrepreneurship, Chairman’s, and Media and Technology Innovation Awards.

Action Items

- Finalize entire drive train design and CAD with mentors to prepare for ordering the baseplate

- Finalize catcher prototype with Abhi

- Finalize control board design with Brandon Gonzalez, Chris Sides, and Abhi Kumar

- Work on pit display with Travis

- Brainstorm ideas for publicity releases for team social media sites for releases throughout the build season: for Jeremy, but he will not be there

- Create and maintain a Gantt chart for Mani

- Help Mani clean up

- Ask a leader for other tasks on the Trello

Day 6: Prototyping the Catcher, Building a New and Improved Flywheel, and Organizing Parts

by Jeffrey Kaufmann

New Flywheel Prototype

A team of students worked on the updated prototype of the flywheel shooter. The new prototype can shoot at an almost vertical angle, enabling the robot to toss the ball over the truss. It also allows for easier packing because its flywheel is smaller than that of the first prototype yet still retains the positives aspects of the original. Some problems occurred during the construction of the new wheel such as broken or splitting wood pieces delaying completion.

This piece had to be replaced. The team attached the curved piece of the flywheel that allows for an approximately 45 degree trajectory.

New Catcher Prototype

A group of students worked on fixing the second catcher prototype. This update will allow for a more mechanically robust device. The rope on the catcher and add a few metal pieces were overhauled today, resulting in a tighter, more stable and cleaner design.

After testing the new mechanism while driving the results were quite satisfactory. The great mobility of the drive granted the ability to quickly get underneath the ball and receive an almost perfect catch.

Programming

The programming team worked hard on the coding on day #6. Today they made it so that the robot can now serve HTML pages. Furthermore, they had to refactor some of the code. In conclusion, while they had to restructure the code, this change did not affect how the code behaved.

Organization of New Equipment

Recently, we received new equipment for the lab, such as soldering devices and other tools. Several students helped organize these new parts and categorized everything received into an Excel document, creating in effect an organized system of all the new equipment within a neat document.

Action Items

- Continue helping Abhi and Dan with catcher prototype and an add intake system.

- Continue helping Ahmed and Paul with shooter prototype improvements

- Continue testing

- Continue working on the drive base CAD with Andrew

Day 1: Kickoff and Game Analysis

Kickoff Overview

Today kicks off the 2014 FRC Season for Team 254. The mentors and students are equally ecstatic for this year’s challenge, Aerial Assist.

Google Drive PDF of the Game Manual:

https://drive.google.com/file/d/0B_TTQ23_FVkAWjM0cjBsbUw1TkU/edit?usp=sharing

Game Animation:

Team Kickoff

Today a group of students attended the 6:30 to 9:30 local San Jose kickoff at Morris Dailey Auditorium. A few others watched the NASA Live Stream from home. Subsequently, at 10, the team met for the team’s kickoff event and discussed the plan for the coming six-week build season. The team then broke up into groups and discussed strategies in terms of necessary robot qualities, priority tasks, and possible scores. The parents and mentors simultaneously discussed logistics and the build plan in more detail until the student leaders returned to present their ideas to the entire group.

Game Analysis

After lunch, about 70 students congregated in the Bellarmine Robotics Lab to examine and better understand the team rules. In particular, they discussed the definitions of assist and possession and clarified the rules for such actions and others on the playing field. For the first two and a half hours, the group went through the relevant sections of the game manual and encouraged group discussion to find possible holes and list them to check with FIRST later. The group noticed some deviations in rules from previous years: the field is two feet narrower at 25 feet, and the match is 30 seconds longer. The autonomous period is five seconds shorter at 10 seconds, and the tele-operated period is 35 seconds longer at 2:20. Andrew Torrance noted the possible issues with battery life with the 25% longer match time. In addition to discussing rules, the team also formulated questions concerning the regulations to ask FIRST:

- Can teams do assists in autonomous?

- Can teams hold balls in autonomous to do an assist later?

- Can a team throw over the truss again to try and get a catch, say, if an alliance earns a successful truss score, but does not successfully catch. Can the alliance try for a second chance? In other words, while the group recognizes that only one truss score counts per cycle, do the truss score and the associated catch score have to be earned on the first attempt?

- Do teams get points (ex. throwing and catching in the end game) immediately, or do the teams only get them once the cycle completes? This is related to the question of assisting in autonomous. Possible answer: Maybe not because autonomous shots are not cycles.

- Teams need clarification on which goalie zone to which the initial position regulations refer. In which goalie zone do teams start if they do not want to start in the white zone? Can human players help in the middle of assists?

- Can human players catch truss scores to make them legal?

- Teams need a better definition of possession for robots in general. For example, for a trough-like robot, is holding the ball as it rolls considered possession? What time period differentiates harmless “deflection” from “possession” of the opponent game object (which earns a severe technical foul penalty)

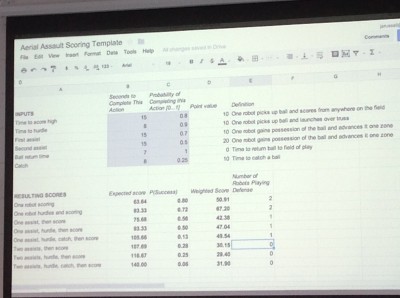

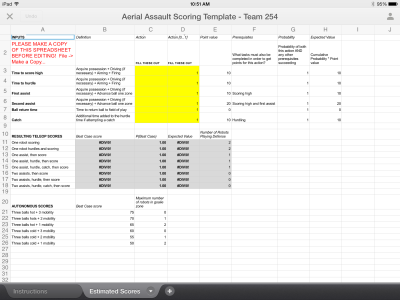

After a short break, the team’s new mentor Jared set up a Google Spreadsheet that evaluated the effectiveness of certain “assist” strategies, with combinations of 1-3 assists, a truss “hurdle,” and the truss “catch.” He took student input for the point values corresponding to each action, the expected time taken for each action, and the probability of the action being carried out successfuly. He then calculated out a rough model of the weighted point values expected from strategies in the tele-operated mode of the match. The group was then able to analyze the efficiency of certain strategies. In the process of discussing strategies, the team also created two other strategy charts and lists (pictured).

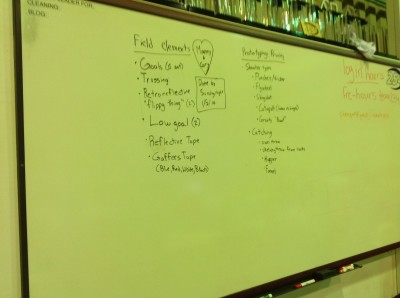

Further Analysis and Prototyping

After dinner, approximately 20 students worked with the mentors to list some possible designs and to plan out the next week’s prototyping schedule. The group prioritized the prototyping of possible modules, specifically shooter designs and catching mechanisms, with design input from students and advice from our experienced mentors. They also discussed what field elements were most necessary for prototyping for the next few weeks and listed them as well. Finally, they discussed the mathematics and physics of shooting a 25-inch, compressible, bulky, and irregular projectile into a 3-foot goal. For example, mentors noted that we might as well design a robot to shoot from farther away from the goal, since the shallower angle of entry would give greater allowance for error. Mentor Paul Ventimiglia also determined that giving the large exercise ball some backspin helped in precision, though it also required more energy to apply both linear force and rotational torque.

Tonight, we mainly focused on the building a preliminary goal with which to prototype before the field arrives and on prototyping and testing the effectiveness of a flywheel shooter and a slingshot shooter. Paul worked primarily with Godwin Vincent, James Holden, Jeremy Tanlimco, Vidur Maheshwari, Miggy Francisco, and Joncarlo Avila to design, sketch, and begin building a prototype for testing the effectiveness of a flywheel on such a large game object. They determined the best wheels with which to work based on their ability to grip the surface of the unusual game object. The prototype design was finalized and they plan to use four large wheels on the same axle hooked up to curved plywood “rims” to optimize the compression on the ball and somewhat minimize the size of the already bulky prototype. EJ Sabathia and Noah Marcel worked on the slingshot design, taping a 2013 Ultimate Ascent Frisbee to surgical tubing and hooking up the system to an alliance wall. The ball consistently bounced about 1/3 of the way down the court, given about 4 or 5 feet of backward stretch.

Lab closing time: 11:00

Action Items

Translation: Future Work Opportunities for Members

- Help Paul with the Flywheel Shooter design

- Help EJ with Slingshot Shooter design

- Help Nick Mercadante machine metal for prototypes

- Ask mentors to begin and lead prototyping projects for other designs